Real-Time Demand Side Energy Management

Annelize Victor Michael Brodkorb

Sr. Business Consultant Business Development Manager Aspen Technology, Inc. Aspen Technology España, S.A.

Houston, TX Barcelona, Spain

ABSTRACT

To remain competitive, manufacturers must capture opportunities to increase bottom-line profitability. The goal of this paper is to present a new methodology for reducing energy costs – “Demand-Side Energy Management.” Learn how process manufacturers assess energy consumption and costs in real-time as decisions are made, lowering energy use, eliminating energy excursions and contract penalties. By integrating process, energy and contract information, Demand-Side Energy

Management allows immediate notification of deviations from dynamic energy targets, eliminating costly delays in identifying and resolving excessive energy use.

The opportunity to get better control over the demand side energy challenge is key to improving target profitability and contribution to the overall business. Through more effective and efficient energy management, companies are able to drive operational excellence and profitability across the entire enterprise.

EXECUTIVE SUMMARY

The demand side of energy management is focused on using the least amount of energy in the production of goods, whereas the supply side is focused on producing energy more efficiently or at the lowest cost. For process industry executives, managing the demand side of energy is a most critical issue. Profitability is being challenged by

unprecedented increases in energy costs. A 2005 Energy Information Administration report (1) states, “The industrial sector used the biggest share of total energy and showed the greatest volatility. Trends in energy supply and demand are linked with such unpredictable factors as the performance of the U.S. economy overall, advances in technologies related to energy production and consumption, annual changes in weather patterns, and future public policy

decisions.” Companies are also faced with reduced personnel and the struggle to take full advantage of plant data while responding more quickly than their competitors. With such daunting challenges in view, business leaders are finding it increasingly difficult to maintain a competitive advantage when it comes to energy.

Demand-Side Energy Management is a cost-effective means towards meeting these challenges. As a production management tool, Demand-Side Energy Management allows manufacturers to proactively manage energy by delivering key plant information in real-time, such as penalties and excursions from normal energy use. This is accomplished by integrat-ing real-time plant, energy, and financial data, and analyzing energy use and cost impacts relative to current plant conditions, dynamic energy targets and energy supply contracts. The methodology then immediately notifies responsible plant operations personnel of deviations from targets and cost impacts, including recommended actions to take. This information enables plant personnel to see deviations, take corrective action and clearly understand the financial impact of their operating decisions.

Value is derived from the ability to make better and faster business decisions regarding the real-time use of energy. This capability provides a large step improvement in value achieved versus traditional use of spreadsheets and energy monitoring.

Companies are able to achieve financial benefits quickly and sustain these benefits, often with little to no capital investment required, thereby driving operational excellence and profitability. INTRODUCTION

The process industry is being significantly impacted by the recent increases in energy costs. According to the U.S. Department of Energy, the percentage of costs attributable to energy range from about 7% to over 30% for the process industries. Because of their intensive energy use, these industries consider energy costs to be an important driver of investment and operating decisions (2). These process industries include manufacturers in chemicals, pulp and paper, metal, mining and agricultural products.

For example, the steep rise in energy and fuel prices can be expected to impact the chemicals industry. Given that energy makes up a large portion of a chemical company’s cost structure, the direction

in which energy prices head plays a key role in determining industry margins (3). Figure 1 illustrates the resulting margin pressure faced by companies in the chemicals process industry.

Figure 1. Margin Pressure in the Chemicals Industry

In addition to these economic factors, business leaders are also faced with the following challenges: • Deregulation of the energy supply market in both

the USA and Europe has generally delivered lower costs for energy; however, external factors have produced increased volatility of prices, significant penalties and even reductions in supply.

• The increased flexibility and broader choices that come with deregulation also increase the

complexity of managing the energy supply at lowest costs.

• Environmental concerns have placed tighter standards and emission regulations on manufacturers worldwide.

Energy-intensive companies must proactively manage these dynamics in order to remain competitive and drive operational profitability. OPPORTUNITIES FOR ENERGY COST REDUCTION – WHAT CAN BE IMPROVED?

Benchmarking studies typically reveal that process energy efficiency varies by about 300% – meaning that the least efficient plants consume about three times more energy than the most efficient (4). A number of factors contribute to this large

performance gap – factors that must be taken into consideration when developing an energy cost reduction strategy. However, determining where to begin presents a real challenge.

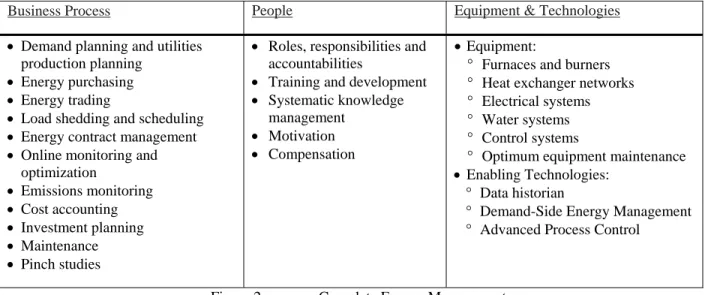

Figure 2 illustrates the numerous elements of a comprehensive energy management program, all of which represent opportunities for energy cost reduction. A plan of action could be as simple as basic housekeeping measures such as repairing steam leaks or as involved as replacing equipment or technology. Each option represents a level of financial investment, from minimal to significant. One must also evaluate whether the chosen option will provide the needed step change in energy performance to drive business profitability.

Demand-Side Energy Management presents a viable and cost-effective option for reducing energy costs. It enables companies to measure and monitor energy use in real time, comparing performance against “intelligent” dynamic targets which are varied to reflect the current operating conditions, and thereby enabling them to proactively manage their demand-side energy costs based on a clear under-

Business Process People Equipment & Technologies

• Demand planning and utilities production planning

• Energy purchasing • Energy trading

• Load shedding and scheduling • Energy contract management • Online monitoring and

optimization

• Emissions monitoring • Cost accounting • Investment planning • Maintenance • Pinch studies

• Roles, responsibilities and accountabilities

• Training and development • Systematic knowledge

management • Motivation • Compensation

• Equipment:

° Furnaces and burners ° Heat exchanger networks ° Electrical systems ° Water systems ° Control systems

° Optimum equipment maintenance • Enabling Technologies:

° Data historian

° Demand-Side Energy Management ° Advanced Process Control

standing of the financial impact of their operating decisions.

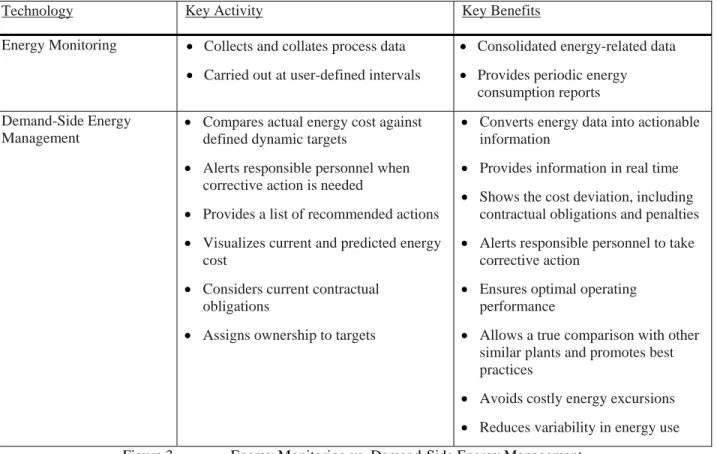

Energy Monitoring vs. Energy Management When considering energy management, it is important to distinguish between energy monitoring and true demand-side energy management. Energy monitoring is a static activity, involving the collection of process data that can be used to

determine energy performance. Demand-Side Energy Management takes this a step farther by converting the data into information/alarms/advice, thereby leading to measurable results. For this reason, Demand-Side Energy Management represents a true dynamic energy management solution.

Figure 3 provides a snapshot view of the key differentiators between energy monitoring and Demand-Side Energy Management.

THE VALUE OF DEMAND-SIDE ENERGY MANAGEMENT

Chemical industry executives must consider the ROI of an energy management program before

funding any such initiative. What is the bottom-line impact? How long will it take to realize value?

Demand-Side Energy Management enables process manufacturers to achieve significant cost and environmental benefits by helping plant sites avoid excess energy consumption in their day-to-day operations. In addition, it is a low-cost methodology to implement, requiring little to no capital expense and delivering payback in typically less than six months.

For energy-intensive chemical processing sites, customer studies show that Demand-Side Energy Management can deliver energy cost reductions in the range of 1-10%. Of course, the actual benefits derived are highly dependent on the specifics of the plant.

Technology Key Activity Key Benefits

Energy Monitoring • Collects and collates process data • Carried out at user-defined intervals

• Consolidated energy-related data • Provides periodic energy

consumption reports Demand-Side Energy

Management

• Compares actual energy cost against defined dynamic targets

• Alerts responsible personnel when corrective action is needed

• Provides a list of recommended actions • Visualizes current and predicted energy

cost

• Considers current contractual obligations

• Assigns ownership to targets

• Converts energy data into actionable information

• Provides information in real time • Shows the cost deviation, including

contractual obligations and penalties • Alerts responsible personnel to take

corrective action

• Ensures optimal operating performance

• Allows a true comparison with other similar plants and promotes best practices

• Avoids costly energy excursions • Reduces variability in energy use Figure 3. Energy Monitoring vs. Demand-Side Energy Management

A few of the primary factors that greatly influence the benefits achieved are as follows: • The energy use of the plant. The overall

efficiency of a process unit will dictate the opportunities for further energy reduction. For a large, energy-intensive process unit in which various improvement initiatives have been implemented over the years, the opportunities for further reduction may yield energy savings in the range of 1-2%. However, for a unit in which energy efficiency is low, greater opportunities for improvement can result in much greater energy savings.

• Variability in energy use. Most chemical

processes experience significant variability in their energy efficiency due to changes in process conditions, different operating strategies and poor control over wasteful practices. As a consequence, plants frequently use more energy than necessary – a situation which is often neglected because plant personnel have access only to historical performance data and cannot react until it is too late. Demand-Side Energy Management enables managers to respond in real-time to deviations from plan. The frequency of deviations will define the benefits potential.

• Use of advanced control and optimization. Use

of advanced control and optimization

technologies will inevitably reduce the amount of unplanned variation in performance. However, Demand-Side Energy Management provides the ability to manage areas of the plant not covered by advanced process control; for example, by taking into account contractual obligations and penalties, Demand-Side Energy Management provides further energy savings not attainable by advanced control.

• A pro-active vs. passive system. Without certain capabilities such as the ability to set true dynamic targets, to alert personnel who have the authority to act and to advise what to do to re-establish optimal operation, the benefits of a pro-active system can be reduced to that of passive energy monitoring.

While the actual benefits of Demand-Side Energy Management will vary from site to site depending on the above criteria, the following standard set of benefits across differing plants and industry sectors applies:

• Can be implemented with little or no capital. • Allows speedy implementation and a rapid return

on investment; typically in the order of just a few months.

• Improves corporate image and shows a commitment to both the workforce and the community in energy efficiency.

• Is a vital component of every company’s operational excellence program.

THE SIX ESSENTIAL STEPS OF DEMAND-SIDE ENERGY MANAGEMENT

Demand-Side Energy Management is the business process of identifying the factors that cause energy use to be higher than necessary and of providing the means to reduce this excess energy use, taking into account energy supply contracts, costs and penalties.

The requirements for achieving effective Demand-Side Energy Management are based on the following six essential steps:

Step 1: Online integrated monitoring of energy related plant data

Energy-related data must be measured and stored in a data historian. An important feature of the monitoring step is the visualization of the information, which should be easy to manage.

Step 2: Sensible, dynamic targets for energy use The targets must be achievable and realistic, based on a clear understanding of operating conditions and a well-defined energy management strategy. Clear ownership of these targets is also vital to ensure that performance meets targeted expectations.

Step 3: Visualization of the real value of deviations from target

By providing the financial impact of deviations in monetary terms, based on real-time contractual costs and penalties, companies are able to better under-stand the financial implications of their operating decisions.

Step 4: Alerting to key deviations sent to responsible personnel

In order to sustain an effective energy management program, alerts must be sent to responsible personnel immediately upon significant deviations from plan, enabling proactive and immediate response. These alerts must be configurable based on the financial cost value of the deviation, thereby ensuring that only deviations meeting set parameters signal an alert for action.

Step 5: Recommended corrective actions Once an alert is given, it is essential that a list of recommended corrective actions is provided, with drill-down capabilities for further analysis if required. By providing this information directly on the

operator’s screen, it helps ensure that the issue is properly and promptly addressed.

Step 6: Prediction of contract penalties

Effective energy management requires a firm under-standing of your energy contracts and the cost effect of penalties. Demand-Side Energy Management allows you to model all the details of your contracts and forecast energy demands in order to predict contract penalties. This information enables plant personnel to better manage energy and avoid unnecessary penalties.

All six elements are required for effective energy cost management. Demand-Side Energy Management enables you to see energy usage and costs in a role– specific, process–specific basis in real-time.

Awareness at the user level, in context of the process, governing contracts and targets, allows the

organization to better manage energy costs. CONCLUSION

Rising energy prices are once again forcing companies in the process industries to examine how they source and use energy. New issues such as strict emissions constraints and the deregulation of utility supply markets add greater complexity to the mix.

Fortunately, technologies exist today for tackling these tough issues. By adopting proven energy management solutions such as Demand-Side Energy Management, companies are able to improve energy efficiency and become more competitive in the marketplace.

Demand-Side Energy Management is a low-cost entry into other more comprehensive energy

management solutions offered by AspenTech. By providing state-of-the-art technologies for addressing the real-world energy management challenges of today and tomorrow, AspenTech is enabling the process industries to gain competitive advantage and maximize operational excellence.

For further information about Aspen Energy Cost Manager, please visit

www.aspentech.com/ecm/index.cfm or send an e-mail to energymanagement@aspentech.com.

REFERENCES

1. Annual Energy Review 2004, published by the Energy Information Administration (EIA), August 2005.

2. U. S. Department of Energy, Office of Industrial Technologies (OIT) Program Mission, FY2001. 3. Valuation of the Chemicals Manufacturing

Industry, Weekly Corporate Growth Report, July 25, 2005.

4. Energy Management – Now Is the Time, George S. Birchfield, Birchfield Consulting LLC, April 2002.