Texture Control and High-Temperature Strength

of Directionally Solidified Al

2O

3/YAG/ZrO

2Eutectic Composite Rods

Yonosuke Murayama

1, Shuji Hanada

2, Jong Ho Lee

3, Akira Yoshikawa

4and Tsuguo Fukuda

4 1Niigata Institute of Technology, Kashiwazaki 945-1195, Japan

2Institute for Materials Research, Tohoku University, Sendai 980-8577, Japan

3Korea Institute of Industrial Technology, Daechondong 958-3, Bukku, Gwang Ju, 500-470, Korea

4Institute of Multidisciplinary Research for Advanced Materials, Tohoku University, Sendai 980-8577, Japan

A2O3/YAG/ZrO2 eutectic Melt-Growth-Composite (MGC) rods with two different microstructures were prepared by unidirectional

solidification using the modified-pulling-down method (MPD) under different processing parameters. Microstructure and crystallographic texture were investigated by X-ray diffraction (XRD), field emission scanning electron microscopy (FE-SEM) and electron backscattered pattern (EBSP) method. High-temperature strength was evaluated by compression tests at 1773 K and 1873 K. Geometric pattern structure and Chinese script pattern structure are evolved by controlling processing parameters. MPD rods have strong preferred growing orientations in Al2O3of

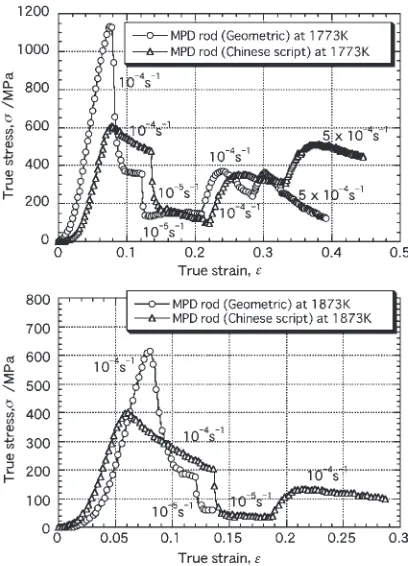

h001ifor the geometric pattern structure and ofh300ifor Chinese script pattern structure. Constituent phases in the MPD rod hold the orientation relationship. The yield stress for the geometric pattern structure is over 1 GPa at 1773 K, which is extremely higher than that for Chinese script pattern structure. High-temperature strength at 1773 K and 1873 K depends on strain rate and temperature in both the MPD rods.

(Received April 14, 2004; Accepted June 8, 2004)

Keywords: Al2O3/YAG/ZrO2 eutectic composite, melt-growth-composite (MGC), crystallographic texture, electron backscattered pattern

(EBSP), high-temperature strength, strength anisotropy

1. Introduction

Recently, the global problems such as an exhaustion of natural resources and an environmental issue are attracting a great deal of attention. The main source of CO2emission in Japan is electric power generation systems. Therefore, one indispensable technology to solve the problem is the development of high-temperature structural material to improve thermal efficiency in gas turbines.1) High-temper-ature structural material, whose operating temperHigh-temper-ature exceeds 1800 K, is required especially in an electric power generation system.1)

Melt-Growth-Composites (MGC) consisting of oxide eutectics, which are directionally solidified by Bridgman method, are candidate materials to meet the above require-ments because of their high strength, excellent oxidation resistance and microstructural stability up to near their melting temperatures.2–9)Especially, it has been reported that the eutectic MGC, which has the characteristic complex microstructure2–11)consisting of interpenetrating single crys-tal oxides,3–7) shows excellent high-temperature perform-ance.

Al2O3/YAG/ZrO2 eutectic MGC rod, which was unidir-ectionally solidified by the modified-pulling-down method (MPD) showed the characteristic complex microstructure similar to the eutectic MGC grown by Bridgman method, which is called Chinese script pattern structure. The growth direction of Al2O3 in the MPD rod ish300i,11)which is the same with Al2O3/YAG or Al2O3/YAG/ZrO2eutectic MGC grown by Bridgman type method.3–7)However, the MPD rod is anticipated to show finer microstructure and higher strength than the MGC because of a higher solidification rate and a larger temperature gradient in the MPD.

It has been revealed that the high-temperature strength of an Al2O3single crystal is the highest inh001idirection,12,13) and the strength of Al2O3-based eutectic MGC is dominated

by orientation of the constituent Al2O3phase. These results suggest that an MPD rod with the Al2O3growing direction of h001iexhibits the highest strength. Recently, we succeeded in growing MPD rods with Al2O3 growing directions of h001i and h300i by controlling processing parameters in crystal growth. So far the strength in h001i direction of constituent Al2O3phase in the MPD rod with Chinese script pattern structure has not been measured, because the MPD rod consists of eutectic grains with different growth orienta-tion. In this paper microstructure, texture and high-temper-ature strength are investigated using the MPD rods with the two kinds of growing directions in Al2O3.

2. Experimental Procedure

An Al2O3/YAG/ZrO2eutectic composite in the shape of a round rod was grown by the MPD method. The starting materials were high-purity commercial powders of-Al2O3, Y2O3 and ZrO2. The mixture of Al2O3, Y2O3 and ZrO2 powders in the mole ratio of Al2O3:Y2O3:ZrO2 = 65:16:19 for the eutectic composition as based on the Lakiza’s work14) was melted in an iridium crucible using a 30 kW radio frequency. The crucible for rod-shaped crystal growth has a circular basal plane whose diameter decides the diameter of the rod. A detailed explanation of MPD is mentioned elswhere.15) The different processing parameters for the MPD rods are summarized in Table 1.

The microstructure was observed by a field emission scanning electron microscope (FE-SEM; FILIPS XL-30) equipped with an electron backscattered pattern (EBSP) apparatus (TexSEM Laboratory). Samples for microstruc-tural observation were polished using a vibratory polisher (BUEHLER VIBROMET 2) with a solution containing alumina powder of 0.05mm. Sample surface was coated with carbon by vacuum evaporation to reduce charging in SEM observation. Since the quality of EBSPs was very sensitive to

surface preparation, samples were ion milled (GATAN 600N). The crystallographic texture was examined by X-ray diffraction and EBSP analysis.

To evaluate the high-temperature strength, compression tests were carried out using rectangular samples with the dimension of 225mm3. The compression tests were conducted in an argon atmosphere at a constant cross head speed at 1773 K and 1873 K, using an Instron testing machine (Instron 8562). A strain rate was changed during compression testing between5104s1and1105s1.

3. Results

3.1 Microstructure

Depending on the processing parameters in Table 1, two different types of microstructures were observed on the whole section perpendicular to the growth direction of an Al2O3/YAG/ZrO2 eutectic MGC grown by the MPD method. One typical example is shown in Figs. 1(a)(c)(e) and the other is in Figs. 1(b)(d)(f). The former and the latter will be called hereafter the geometric pattern and Chinese script pattern structures. In the micrograph of MPD rod with the geometric pattern structure, cell boundaries, where inter-lamellar spacing is irregular, are observed at a low magni-fication (Fig. 1(a)). In addition, rectangular maze-like eutectic structure of Al2O3 and ZrO2 is evolved at a high magnification (Fig. 1(c)). Both the phases are well elongated along the growth direction, as seen in Fig. 1(e).

SEM observation of a MPD rod with Chinese script pattern structure indicated that the cross-section was composed of several eutectic grains with different shading contrasts, as shown previously.11) Each eutectic grain consists of Al2O3, YAG and ZrO2, as seen in Figs. 1(b), (d) and (f). Although the constituent phases have a tendency to be elongated in the growth direction as shown in Fig. 1(f), their growth directions are considerably scattered, compared to those in the geo-metric pattern structure in Fig. 1(e).

3.2 Crystallographic texture

The crystallographic texture at a cross section perpendic-ular to the growth direction was evaluated by X-ray diffraction and EBSP analysis. The X-ray diffraction pattern on a cross-section perpendicular to the growth direction is shown in Fig. 2. There is a distinct difference between the geometric pattern and Chinese script pattern structures concerning the presence of peaks of Al2O3 h300i. No apparent peak of Al2O3 h300i can be seen in the geometric pattern structure, while Al2O3h006ipeak is clearly observed

The pole figures of the constituent phases at a central area of the MPD rods, which are obtained by EBSP analysis at a cross section perpendicular to the growth direction, are shown in Fig. 3. The pole figures indicate clearly that the preferred growing orientations areh001ifor Al2O3andh220i for ZrO2 in the geometric pattern structure and h300i for Al2O3andh100ifor ZrO2in Chinese script pattern structure. No definite orientation relation between Al2O3 and ZrO2 is observed in the MPD rods with the geometric and Chinese script pattern structures, but there seems to be=4rotational relation aroundh110iof Al2O3orh100iof ZrO2in both the structures.

The {800} pole figure of YAG shows that the h100i orientation deviates from the growth direction in the geo-metric and Chinese script pattern structures, althoughh400i andh800ipeaks are observed in X-ray diffraction profiles in Fig. 2. The analyzed orientations of YAG seem to scatter probably because of less reliability of EBSP analysis arising from insufficient sample surface preparation as well as intrinsic scattering in orientation. Some accumulated peaks of the growth direction are shown in the inverse pole figures in Fig. 4. The inverse pole figure of Al2O3 in Chinese script pattern structure indicates clearly that the preferred growth directions are near h100i and h010i. The formation of dominant h100i and h010i directions can be explained by twinning.10,11,13)These twins may form to minimize compat-ibility strain at the interface between the two variants during the growing process. ZrO2 indicates preferred direction of h001i. On the other hand, in the geometric pattern structure Al2O3has no preferred growing direction, but ZrO2has weak preferred direction deviated from h101i. YAG in both the structures seems to show some weak accumulated peaks in the growth direction.

3.3 High-temperature deformation behavior

[image:2.595.45.292.82.187.2]4. Discussion

4.1 Microstructure and texture

Al2O3/YAG/ZrO2 eutectic MGC consists of single crystal-like Al2O3, YAG and ZrO2. Mechanical properties of the MGC at elevated temperatures would be controlled by crystallographic orientation of Al2O3, since Al2O3 with hexagonal crystal structure exhibits significant orientation dependence of strength,16–18) while YAG and ZrO

2 with cubic crystal structure shows almost no anisotropy in strength.19–21) Therefore, in addition to microstructures the crystallographic texture of the constituent phases should be considered to understand the strength of the MGC rods.

The preferred growing direction of Al2O3in Al2O3/YAG/ ZrO2eutectic MGC has been reported to beh300iin the MPD rod with Chinese script pattern structure. Though the different processing parameter in Table 1 is found to produce either geometric pattern structure or Chinese script pattern structure, it is not clear at present which parameter determines the preferred growing orientation. A preferred growing orientation other thanh300ihas never been reported

Fig. 1 FE-SEM micrographs of MPD rods with Geometric pattern structure, (a), (c) and (e) and Chinese script pattern structure, (b), (d) and (f). (a)–(d) are cross-sections perpendicular to the growth direction. (e) and (f) are cross-sections parallel to the growth direction.

[image:3.595.97.499.70.485.2] [image:3.595.48.291.560.759.2]for Al2O3in eutectic MGC grown by Bridgman type method. This difference will be associated with a seeding process. Bridgman type method not using a seed crystal needs a lower solidifying rate and a smaller temperature gradient for the crystal growth, compared with the MPD method. Al2O3/ YAG binary eutectic MGC grown by the MPD method showedh300ipreferred growing orientation of Al2O3, even though an Al2O3seed crystal withh001iwas used. However, Al2O3/YAG/ZrO2ternary eutectic MGC grown by the MPD method showed occasionally mixed preferred orientations of h300i andh001i of Al2O3 in a cross-section. Al2O3 phase grown from a h001i seed crystal in Al2O3/YAG binary

eutectic MGC rotates toh300i orientation obeying the twin relation and forms the Chinese script pattern structure with other phases. The interphase orientation relation between Al2O3 and ZrO2 may give an important influence on the preferred growing orientation. The formation of fine eutectic

Fig. 3 Pole figures at cross-section perpendicular to the growth direction of MPD rod with Geometric pattern structure and Chinese script pattern structure.

Fig. 4 Inverse pole figures of growth direction obtained from EBSP analysis.

[image:4.595.129.469.71.347.2] [image:4.595.324.528.401.684.2] [image:4.595.49.292.402.591.2]microstructure of Al2O3/ZrO2with interphase orientation of h001iAl2O3k h110iZrO2 may make the rotation of Al2O3

impossible.

Figure 6 shows pole figures by EBSP analysis at another cross section of the same MPD rod as in Fig. 3. By comparing the pole figures in Figs. 3 and 6, it is found that the crystallographic orientation distributions are different in the same rod. The MPD rod with Chinese script pattern structure has distinct eutectic grain boundaries.11)Each eutectic grain seems to be a single crystal and has almost the same preferred growing direction. However, the crystallographic orienta-tions of eutectic grains are changed each other by rotation of the crystallographic orientation around the growth direc-tion.11)The MPD rod with the geometric pattern structure has no distinct eutectic grain boundaries, but has cell boundaries. The adjacent cells and their cell boundaries showed a very small difference in crystallographic orientation, which was confirmed by the EBSP analysis around interface boundaries. There is a definite difference between distant cells as shown in Fig. 6. However, they have almost same preferred growing direction,i.e.h001iof Al2O3in the MPD rod with geometric pattern structure and h300i in the MPD rod with Chinese script pattern structure.

4.2 Texture and high-temperature strength

The flow stress of MPD rod with geometric pattern structure decreases drastically after showing a peak stress as shown in Fig. 5. Figure 7 shows the compressed MPD rods with geometric and Chinese script pattern structures at 1873 K. The rod with Chinese script pattern structure deforms throughout the rectangular specimen, while the rod with the geometric pattern structure deforms severely only at sample edges. Moreover, in the geometric pattern structure brittle fracture occurs along the growth direction like bundled

firewood. This may be caused by preferential crack prop-agation along weak cell boundaries. However, since the severe deformation at the sample edges and the firewood-like fracture take place at a strain after the peak stress, the 0.2% proof stress measured from the stress-strain curves may be controlled by the strength of the constituent single crystals.

It has been pointed out that the strength anisotropy in the Al2O3/YAG eutectic MGC is associated with the orientation dependence of high-temperature strength of single crystal Al2O3.13) The high-temperature strength obtained in this experiment is compared with the strength of single crystals of Al2O3,16–18)YAG19)and ZrO220,21)as shown in Fig. 8. It is considered that the single crystals YAG and ZrO2with cubic crystal structure show a very small anisotropy in high-temperature strength. On the other hand, Al2O3 with hexagonal structure shows the strong anisotropy. Since the primary slip system of-Al2O3 is (001)1/3h11110ibasal slip above 1000 K,22)the strength of Al

2O3depends on the angle between testing direction and c-axis. As seen in Fig. 8, the high temperature strength of Al2O3decreases remarkably by only 6 deviation of testing direction from c-axis of Al2O3,

though the strength at c-axis is comparable to that of YAG. There are no available data on the strength of cubic ZrO2 at

Fig. 6 Pole figures of Al2O3at same cross-section. Orientation of each

phase in other eutectic grain rotates about growth direction.

Fig. 7 Appearance of specimens after compression test at 1873 K. (a) MPD rod with geometric pattern structure. (b) MPD rod with Chinese script pattern structure.

Fig. 8 Relationship between strain rate and compressive strength for Al2O3/YAG/ZrO2 eutectic composite, single crystal Al2O3, YAG and

[image:5.595.55.283.70.327.2] [image:5.595.348.507.76.185.2] [image:5.595.321.533.550.747.2]structure is on the average of the strength values of single crystals YAG and Al2O3 deformed to a-axis. The micro-structural morphology of MPD rod seems to consist of two laminates with even volume fraction, in which one laminate is eutectic layer of Al2O3 and ZrO2 and the other is YAG. Though the influence of ZrO2 on strength is vague, the strength of MPD rod seems to obey the mixture rule of the constituents composed of oriented single crystals.

5. Conclusions

Al2O3/YAG/ZrO2 eutectic MGC rods with two different microstructures and preferred growth orientations were grown by the modified-pulling-down method and high-temperature strength was investigated. The main conclusions about texture and high-temperature strength of MPD rod with are as follows.

(1) Two different microstructures, geometric and Chinese script pattern structures, are obtained by controlling processing conditions.

(2) Preferred growth orientations of MPD rod areh300iin Al2O3 and h100i in ZrO2 for Chinese script pattern structure and h001i in Al2O3 and h220i in ZrO2 for geometric pattern structure. YAG has no distinct preferred growth orientation, though several peaks are observed in the inverse pole figure.

(3) Compressive strength exceeding 1 GPa at 1773 K in the growth direction of MPD rod with geometric pattern structure is much higher than that with Chinese script pattern structure.

(4) Flow stress of MPD rod with both geometric and Chinese script pattern structures shows strain rate and deformation temperature dependence in compression tests at 1773 K and 1873 K.

(5) Strength of MPD rod is comparable to the strength of

REFERENCES

1) A. Nitta: J. JSME99(1996) 251–256.

2) T. A. Parthasarathy, T. Y. Mah and L. E. Matson: J. Am. Ceram. Soc.

76(1993) 29–32.

3) Y. Waku, N. Nakagawa, H. Ohtsubo, Y. Ohsora and Y. Koutoku: J. Japan Inst. Metals59(1995) 71–78.

4) Y. Waku, H. Ohtsubo, N. Nakagawa and Y. Koutoku: J. Mater. Sci.31

(1996) 4663–4670.

5) Y. Waku, N. Nakagawa, T. Wakamoto, H. Ohtsubo, K. Shimizu and Y. Kohtoku: Nature389(1997) 49–52.

6) Y. Waku, S. Sakata, A. Mitani and K. Shimizu: Mater. Res. Innov.15

(2001) 94–100.

7) Y. Waku, S. Sakata, A. Mitani, K. Shimizu and M. Hasebe: J. Mater. Sci.37(2002) 2975–2982.

8) B. M. Epelbaum, A. Yoshikawa, K. Shimamura, T. Fukuda, K. Suzuki and Y. Waku: J. Crystal Growth198/199(1999) 471–475.

9) J. H. Lee, A. Yoshikawa, T. Fukuda and Y. Waku: J. Cryst. Growth231

(2001) 115–120.

10) C. S. Frazer, E. C. Dickey and A. Sayir: J. Cryst. Growth233(2001) 187–195.

11) Y. Murayama, J. H. Lee, A. Yoshikawa, S. Hanada and T. Fukuda: Mater. Trans.45(2004) 303–306.

12) H. Yoshida, A. Nakamura, T. Sakuma, N. Nakagawa and Y. Waku: Scr. Mater.45(2001) 957–963.

13) Y. Murayama, S. Hanada and Y. Waku: Mater. Trans.44(2003) 1690– 1693.

14) S. M. Lakiza and L. M. Lopato: J. Am. Cerami. Soc.80(1997) 893– 902.

15) J. H. Lee: Doctoral Thesis, Tohoku University (2001).

16) D. M. Kotchick and R. E. Tressler: J. Am. Ceram. Soc.63(1980) 429– 434.

17) G. S. Corman: Ceram. Eng. Sci. Proc.12(1991) 1745–1766. 18) D. J. Gooch and G. W. Groves: J. Mater. Sci.8(1973) 1238–1246. 19) G. S. Corman: J. Mater. Sci.12(1993) 379–382.

20) T. A. Parthasarathy and R. S. Hay: Acta Mater.44(1996) 4663–4676. 21) U. Messerschmidt, D. Baither, B. Baufeld and M. Bartsch: Mater. Sci.

Eng.A233(1997) 61–74.