Optimum Oil Yield from Egyptian Jatropha Seeds

Using Screw Press

Said M.A. Ibrahim

a, K.A. Abed

b, M.S. Gad

b, H.M. Abu Hashish

b* aMechanical Engineering Department, Faculty of Engineering, Al-Azhar University, Cairo, Egypt. b Mechanical Engineering Department, Engineering Research Division, National Research Centre, Giza, Egypt.

* Corresponding author: HM.AbuHashish@nrc.sci.eg

Abstract-- There is heavy dependence on fossil fuels for energy production. These are not only depletable but also are the main cause of emissions and global warming. Renewable energy and biofuels can play significant role in this concern. This research is concerned with the efficient production of biodiesel from Jatropha seeds. We designed and operated an efficient screw press for continuous production of biodiesel. The effects of many parameters which affect the oil yield from the press were studied in order to determine the optimum operating conditions for maximum yield.

The objective of this paper is to obtain the optimum speed and preheating temperature of our screw press to get improved properties of extraction oil, minimum extraction time and minimum motor power. The present screw press is specially designed on laboratory scale. The influence of different motors speeds of 20, 60, 100 and 140 rpm and preheating temperatures 50, 75, 100 and 125 °C on oil extraction yield were investigated.

The results show that extraction Jatropha oil by screw press is more efficient in producing Jatropha yield than other methods. There is a limiting minimum extraction temperature for reducing free fatty acid percentage in the produced oil. An extraction temperature of 75 or 100 °C at motor speed of 20 or 60 rpm give the maximum Jatropha extraction yield. These conditions also are related to low motor power and torque.

Index Term-- Screw press - Jatropha Yield – Temperature – Speed – Power

1. INTRODUCTION

Due to the oil crisis and global warming, a lot of research has been directed to find suitable alternative fuels to petroleum oil. Jatropha trees can be cultivated in deserts and sewage bonds. Jatropha oil can be extracted chemically or by using mechanical presses. Edible vegetable oil has higher price, so we move to produce biodiesel from non-edible vegetable oils. Biodiesel is becoming now environmental and attractive alternative to fossil fuels with a lot of benefits [1].

Jatropha oil is in edible nature without detoxification is the best of its attractive points to be used as substitute energy source and fuel. Jatropha plant is a multipurpose shrub belonging to Euphorbiaceae group, but it is growing best in tropic and sub-tropic parts in Africa and Asia. Jatropha oil can be converted to biodiesel by using transesterification process, or as oil directly in diesel engines or burners [2, 16].

The old extraction methods for extracting oil from seeds use manual and simple implements; these now are of less use. Jatropha oil extraction may be done mechanically (by pressing the kernels), chemically and enzymatically [3, 4, 5]. Nowadays, there are new methods such as ultra-sonication and using chemicals in aqueous enzymatic

treatment. The maximum yield for aqueous enzymatic method is around 74%. Oil expellers have been used for oil extraction from Jatropha seeds. The most known types of expellers are Sundhara (or Sayari) oil expeller and Komet expeller. Electrician expellers such as single screw Komet expeller also extract oil from Jatropha seeds. It is rather important to design the screw press for producing higher yield and acceptable oil physical properties [6, 7].

In Ref [8, 15] the cooked seeds were screw pressed immediately after cooking using a heavy-duty laboratory screw press. The main screw was driven by a 20 hp motor equipped with a variable frequency drive. The cored main barrel (or cage) had a diameter of 8.9 cm. The barrel’s length/diameter (L/D) ratio was 8.3. The cage had four drainage sections of 14.0 cm/section [8]. Oyinlola et al [9] employed a stationary screw press with cylindrical barrel and helical screw supported on a conical shaft supported by bearings with the shaft rotating in it. The hopper fed the screw with the oil seed to be pressed inside the cylindrical barrel and the cake is passed from the other end of the barrel and the oil is discharged through small holes in the barrel bottom [9].

Experiments were conducted to determine the effects of moisture content, cooking temperature, and cooking time on the yield of oil mechanically expressed from Jatropha seed using a screw press expeller. A maximum oil recovery of 73.14% was obtained when Jatropha seeds were conditioned to a dry basis, moisture level of 9.69% and cooked at 110 °C for 10 minutes [10]. Screw press oil recovery, residual oil, pressing rate, and oil sediment content were measured at different moisture contents for uncooked and cooked seeds. At optimum processing conditions, oil recovery from cooked seed was 7% higher than that of uncooked seed [10].

The influence of pressure, temperature and moisture content on the oil yield for sesame, linseed, rapeseed, palm kernel, Jatropha and Egyptian Jatropha were studied. Yield is increased with increase in pressure and temperature [11]. For both sesame and linseed, maximum oil yield was obtained at a moisture content of about 4 wt. %. Maximum yields obtained were 45–55 wt.% (oil/oil) for hulled seeds such as linseed, rapeseed, palm kernel, Jatropha and 70–75 wt.% (oil/oil) for dehulled seeds such as sesame and Jatropha. Rate of extraction increased with an increase in temperature and a decrease in moisture content. Furthermore, the rate of pressing was described by the Shirato model. The increased creep, and thus decreased rate of pressing, observed with increased moisture content was satisfactorily described by the Shirato model [11].

conventional methods have many in common with Soxhlet, in the sense that they are time consuming and require large amount of solvents. On the other hand, they are relatively simple both in performance and fundamentals, so their development does not require specialized personnel. Finally, these methods are cheap, which favored significantly their widespread use particularly both in industries and laboratories [12]. Solvent extraction of edible oil from oil seeds can be carried out through two traditional processes which are mechanical and solvent extractions. For seeds with high oil content such as sunflower seeds, groundnuts, palm kernels or rapeseed. Seeds of lower oil content, such as soybeans, can be directly solvent extracted [13].

The pretreatment of Jatropha seeds for oil extraction contributes to 24% of the total internal energy destroyed for solvent extraction processes and 66% for mechanical extraction. The pretreatment unit alone degrades so much quality energy in the Jatropha seeds before actual oil extraction. When the pretreatment unit processes are improved, mechanical extraction would be more efficient. Solvent extraction of Jatropha Seeds oil is 79% efficient based on thermodynamics. Mechanical extraction of Jatropha seeds oil is 96% efficient. Mechanical extraction is therefore found to be more efficient than solvent extraction [10]. One of the most future options for alternative of fossil fuels is the use of liquid fuels produced from transesterification process of Jatropha oil to produce biodiesel [14].

The objective of this work is to find the effect of mechanical extraction method using screw press on the yield and psychochemical properties of the extracted oil. A screw press was designed, manufactured and tested for this purpose. The main goal is to produce Jatropha oil from Jatropha seeds with the higher possible extraction yield. The effects of screw motor speed and extraction temperature on extraction yield, time of extraction and screw power were investigated. The results give the optimum screw motor speed and extraction temperature to achieve the maximum extraction yield. A new design of screw press was manufactured to produce maximum oil yield from Jatropha seeds cultivated in Egypt. It is important to paint out that our research is applied to Egyptian Jatropha since the origin of the seeds affect their properties and hence their oil yield could differ significantly. The oil extraction conditions also differ.

2. MATERIALS AND METHODS

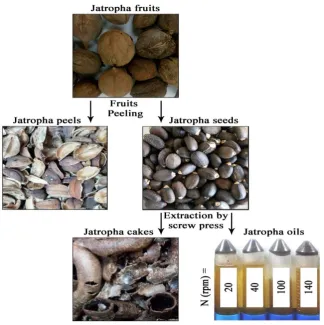

Our Jatropha fruits were obtained from the Agriculture Research Center, Giza, Egypt. Jatropha seeds come from upper Egypt, where it is cultivated in high temperature dry weather conditions. The seeds were handpicked and grouped into good maturity according to its skin brown color. Jatropha was peeled manually, Jatropha peels and its cake were used as animal feed stuff after removing poisonous materials. The sequence of oil extraction from Jatropha fruits to the final products in depicted in Fig. 1.

Fig. 1. Schematic diagram of Jatropha oil extraction process. 2.1 Mechanical Pressing Extraction Method

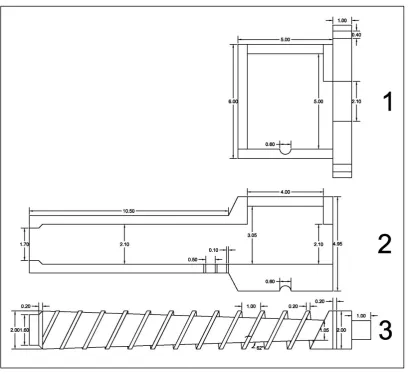

The present screw press is comprised of three main parts: the base, the housing and the screw. These

base and housing have holes on top of each other to feed the seeds to the rotating screw. The oil is collected from a hole

in the housing from underneath.

Fig. 2. The main components of the screw press. (1) Base, (2) Housing, (3) Screw. Mechanical pressing is a continuous extraction

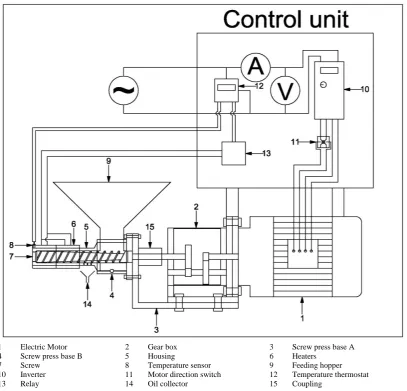

method. It produces a large amount of oil from the seeds of up to 20%. Because of its higher yield as an extraction process, the screw press is considered a continuous process. This led to the design and manufacturing of a screw press used for the production of Jatropha oil by continuous method. The present screw press is driven by an electric motor supported with a gearbox to decrease its rotational

speed. The rotational speed is varied by a frequency inverter; a direction switch is used to inverse the motor speed direction. Heaters are used to preheated Jatropha seeds and a temperature thermostat is used for temperature control. A photograph of the press and associated parts is given in Fig. 3. Figure 4 shows a diagram of the present

screw press and its intimate parts.

1 Electric Motor 2 Gear box 3 Screw press base A

4 Screw press base B 5 Housing 6 Heaters

7 Screw 8 Temperature sensor 9 Feeding hopper

10 Inverter 11 Motor direction switch 12 Temperature thermostat

13 Relay 14 Oil collector 15 Coupling

1 Electric Motor 2 Gear box 3 Screw press base A

4 Screw press base B 5 Housing 6 Heaters

7 Screw 8 Temperature sensor 9 Feeding hopper

10 Inverter 11 Motor direction switch 12 Temperature thermostat

13 Relay 14 Oil collector 15 Coupling

Fig. 4. Main parts of the screw press and associated parts. 2.2 Experimental procedure

The oil extraction was performed using a specially designed laboratory scale mechanical screw press. The experiments were conducted in factorial arrangement, with four speeds of 20, 60, 100 and 140 rpm, at extraction temperatures of 50, 75, 100 and 125 °C. The effect of motor

rotational speed and extraction temperature on the oil extraction yield was studied. Figure 5 illustrates the color of the extraction oil from the press for different preheated seed temperatures, T, and press speed, N. It is important to mention that the preheating temperature is limited to 100 °C in order not to increase the undesirable fatty acids in the oil.

Fig. 5. Color of extracted oil for different T and N.

3. RESULTS AND DISCUSSIONS

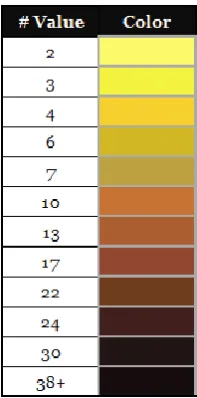

The extraction temperature changes the oil color and hence the oil quality as show in Fig. 5. Oil extraction color is represented by Lovibond scale as indicated in Fig. 6. Oil extraction colors at different motor speeds and extraction temperatures are presented in Table 1. The chemical and

physical properties are affected by the extraction temperature. The oil extraction is hydrolyzed and oxidized according to the applied temperature. Higher speeds and higher extracting temperatures have darker color oil. The darker color of the extracted oil at higher temperature is caused by oxidation during the extraction process.

Table I

The effect of Speed and temperature on color of Jatropha oil.

No. Speed

(RPM)

Temperature (°C)

Lovibond scale value

Jatropha oil samples

1 40 50 3

2 60 50 6

3 100 50 10

4 140 50 13

5 20 75 4

6 60 75 6

7 100 75 10

8 140 75 13

9 20 100 7

10 60 100 6

11 100 100 10

12 140 100 7

13 20 125 24

14 60 125 13

15 100 125 10

16 140 125 17

3.1 Effect of extraction temperature and screw speed on oil extraction yield

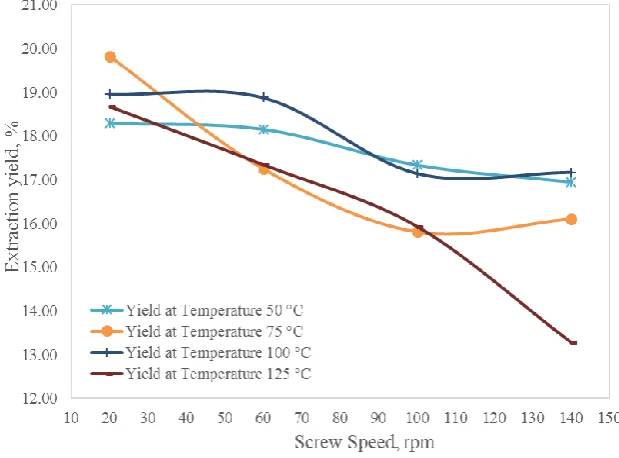

Jatropha oil yield by a mechanical expeller can extract more than 80% mass fraction of oil in comparison with the reference Soxhlet method. Soxhlet extraction method is ideal because it can extract 95 to 98% mass fraction of available oil in Jatropha seeds [1]. Maximum extraction yield from Egyptian Jatropha by Soxhlet is only about 25%. Egyptian Jatropha contains little oil as a species in caparison of seeds from other origins. The results given in Fig. 7 suggest that the present maximum oil yield is about 20 %,

which corresponds to 80% mass fraction of oil in seeds in comparison with Soxhlet method and it is obtained at a motor speed of 20 rpm and preheating temperature of 75 °C. This proves that the present screw press is efficient and well designed for getting a good oil extraction yield from Jatropha seeds. However, at these extraction conditions, much time is consumed associated with higher motor power and torque. The maximum yield is obtained for temperatures between 75-100°C. For a speed of 60 rpm the yield is slightly less but the power and torque are much less as will be discussed later.

Fig. 7. Effect of extraction temperature and rotational speed on oil extraction yield. 3.2 Effect of extraction temperature and screw speed on

oil extraction time

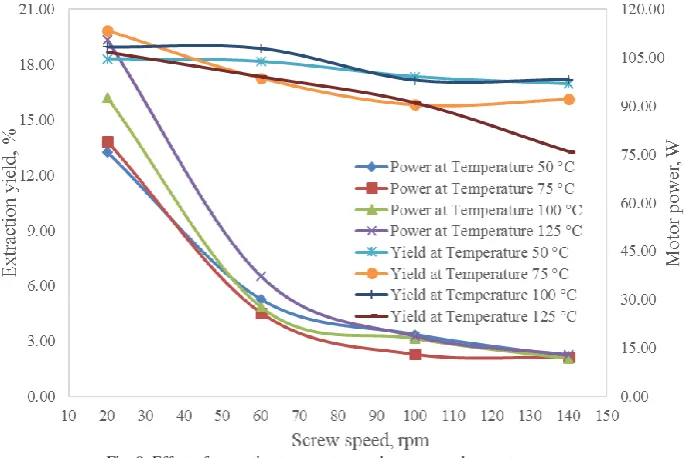

Extraction time is almost the same for all extraction temperatures at screw speeds between 60 to 125 rpm.

Fig. 8. Effect of extraction temperature and screw speed on oil extraction time.

3.3 Effect of extraction temperature and screw speed on motor power

Motor power is nearly the same for all extraction temperatures at screw speeds between 60 to 125 rpm. Motor

power increases as the extraction temperature increases at lower speeds. The less power is obtained for maximum yield at speed of 60 rpm and extraction temperature of 100 °C as show in Fig. 9.

Fig. 9. Effect of extraction temperature and screw speed on motor power.

3.4 Effect of extraction temperature and screw speed on motor torque

Motor torque is the same for all extraction temperatures at screw speeds between 60 to 125 rpm. The

Fig. 10. Effect of extraction temperature and screw speed on motor torque.

3.5 Optimum extraction yield of screw press

The maximum extrication yield from measurements is 19.83% at a screw speed of 20 rpm and extraction preheating temperature of 75 °C. Increase of screw speed and extraction temperature led to decrease of motor power, extraction time and extraction yield. Lower screw speeds and medium extraction temperature produced higher extraction yield.

The minimum extrication yield from measurements is 13.29% at a screw speed of 140 rpm and extraction

temperature of 125 °C. Higher screw speeds and higher extraction temperature resulted in lower extraction yield.

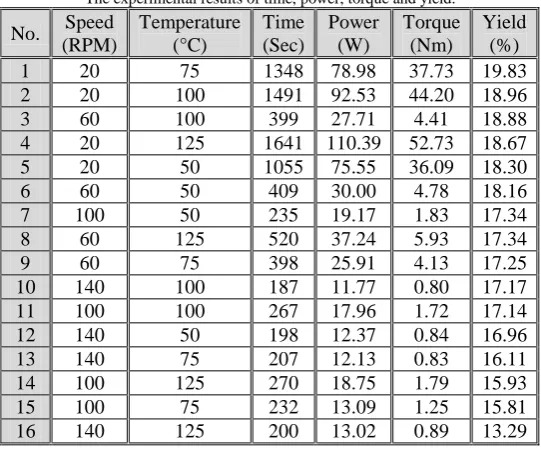

The present screw press was designed, manufactured and operated to produce the maximum extraction oil yield. We studied the effect of screw speeds of 20, 60, 100 and 140 rpm and extraction temperature of 50, 75, 100 and 125 °C. Increase of screw speed from 20 to 140 rpm and increase of extraction temperature from 50 to 140 °C, led to decrease of extraction yield by 35% as shown in Table 2.

Table II

The experimental results of time, power, torque and yield.

No. Speed (RPM)

Temperature (°C)

Time (Sec)

Power (W)

Torque (Nm)

Yield (%)

1 20 75 1348 78.98 37.73 19.83

2 20 100 1491 92.53 44.20 18.96

3 60 100 399 27.71 4.41 18.88

4 20 125 1641 110.39 52.73 18.67

5 20 50 1055 75.55 36.09 18.30

6 60 50 409 30.00 4.78 18.16

7 100 50 235 19.17 1.83 17.34

8 60 125 520 37.24 5.93 17.34

9 60 75 398 25.91 4.13 17.25

10 140 100 187 11.77 0.80 17.17

11 100 100 267 17.96 1.72 17.14

12 140 50 198 12.37 0.84 16.96

13 140 75 207 12.13 0.83 16.11

14 100 125 270 18.75 1.79 15.93

15 100 75 232 13.09 1.25 15.81

16 140 125 200 13.02 0.89 13.29

The absolute results as grouped in Table II do not in fact give the optimum conditions for maximum oil yield as far as the effective studied variables are concerned for instance if we looked at conditions 1 and 3 in Table 2, we observe clearly that the time consumed for 60 rpm and 100 °C is almost 3 times less than that for conditions 1 which gives the maximum yield for a little difference of yield of 0.87%.

exceeding 60 rpm and 100 °C respectively. These are abundantly significant conclusions of the present research.

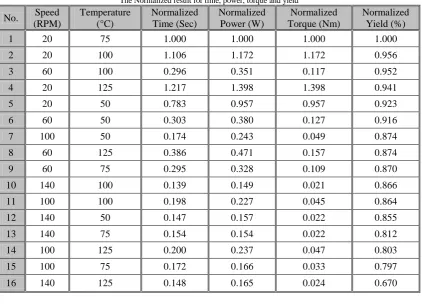

To put our results into prospective the normalized time, power, torque and yield are determined and are given in Table 3. The normalized values are obtained relative to

the reference values of condition 1 in Table 2. The users of our results can choose the favorite conditions for their applications bearing in mind the limiting prementioned speeds and temperatures.

Table III

The Normalized result for time, power, torque and yield

No. Speed (RPM) Temperature (°C) Normalized Time (Sec) Normalized Power (W) Normalized Torque (Nm) Normalized Yield (%)

1 20 75 1.000 1.000 1.000 1.000

2 20 100 1.106 1.172 1.172 0.956

3 60 100 0.296 0.351 0.117 0.952

4 20 125 1.217 1.398 1.398 0.941

5 20 50 0.783 0.957 0.957 0.923

6 60 50 0.303 0.380 0.127 0.916

7 100 50 0.174 0.243 0.049 0.874

8 60 125 0.386 0.471 0.157 0.874

9 60 75 0.295 0.328 0.109 0.870

10 140 100 0.139 0.149 0.021 0.866

11 100 100 0.198 0.227 0.045 0.864

12 140 50 0.147 0.157 0.022 0.855

13 140 75 0.154 0.154 0.022 0.812

14 100 125 0.200 0.237 0.047 0.803

15 100 75 0.172 0.166 0.033 0.797

16 140 125 0.148 0.165 0.024 0.670

4. CONCLUSIONS

The present results lead to these conclusions:

1. Our screw press proved successful and reliable to extract oil from Egyptian Jatropha seeds with optimum yields for different operating conditions

2. The optimum yield should be related to time, temperature, motor power and motor torque.

3. There are limiting temperatures of 75 -100 °C and speeds of 20 – 75 rpm. These are in order to obtain oil with the proper properties, better yield and favorable screw operating conditions.

4. Lower extraction temperature and screw speed also increase oil yield but will increase extraction time, motor power and torque.

5. Higher extraction temperature and screw speed also decrease oil yield but will decrease extraction time, motor power and torque.

6. This study indicated that the maximum applicable extraction temperature and screw speed for extraction Jatropha oil is 100 °C and 60 rpm. These conditions give also low motor power and torque.

7. Increasing extraction temperature increase free fatty acid but 100 °C is normal free fatty acid from Lovibond scale.

REFERENCES

[1] Raja, S.A., Smart, D.S.R. and Lee, C.L.R. Biodiesel production

from jatropha oil and its characterization. Research Journal of Chemical Sciences, 2011. 1(1): p. 1-7.

[2] Achten WMJ, Verchot L, Franken YJ, Mathijs E, Singh VP,

Aerts R, et al. Jatropha biodiesel production and use. Biomass Bioenerg 2008;32(12):1063e84.

[3] Koh, M.Y. and Ghazi, T.I. Mohd. A review of biodiesel

production from Jatropha curcas L. oil. Renewable and Sustainable Energy Reviews, 2011. 15(5): p. 2240-2251.

[4] Shah S, Sharma A, Gupta MN. Extraction of oil from Jatropha

curcas L. seed kernels by enzyme assisted three phase partitioning. Ind Crop Prod 2004;20(3):275e9.

[5] Shah S, Sharma A, Gupta MN. Extraction of oil from Jatropha

curcas L. by combination of ultrasonication and aquaeous enzymatic oil extraction. Bioresour Technol 2004;96:121e3.

[6] Kumar A, Sharma S. An evaluation of multipurpose oil seed

crop for industrial uses (Jatropha curcas L.): a review. Ind Crops Prod 2008;28(1):1e10.

[7] Sirisomboon P, Kitchaiya P, Pholpho T, Mahuttanyavanitch W.

Physical and mechanical Properties Of Jatropha curcas L. fruits, nuts, and kernels. Biosyst Eng 2007;97:201e7.

[8] Evangelista, R.L., T.A. Isbell, and S.C. Cermak, Extraction of pennycress (Thlaspi arvense L.) seed oil by full pressing. Industrial Crops and Products, 2012. 37(1): p. 76-81.

[9] Oyinlola, A., A. Ojo, and L.O. Adekoya, Development of a

laboratory model screw press for peanut oil expression. Journal of Food Engineering, 2004. 64(2): p. 221-227.

[10] Pradhan, R.C., et al., Oil expression from Jatropha seeds using a

screw press expeller. Biosystems Engineering, 2011. 109(2): p. 158-166.

[11] Willems, P., N.J.M. Kuipers, and A.B. De Haan, Hydraulic

of yield and pressing rates. Journal of Food Engineering, 2008. 89(1): p.61-8 .

[12] u ue de astro . . and . . arc a-Ayuso, Soxhlet

extraction of solid materials: an outdated technique with a promising innovative future. Analytica Chimica Acta, 1998. 369(1–2): p. 1-10.

[13] Sriti, J., et al., Oil extraction from coriander fruits by extrusion and comparison with solvent extraction processes. Industrial Crops and Products, 2011. 33(3): p. 659-664

[14] Ofori-Boateng, C., L. Keat Teong, and L. JitKang, Comparative

exergy analyses of Jatropha curcas oil extraction methods:

Solvent and mechanical extraction processes. Energy

Conversion and Management, 2012. 55: p. 164-171.

[15] Evangelista, R.L., Cermak, S.C., 2007. Full-press oil extraction

of cuphea (PSR23) seeds. J. Am. Chem. Soc. 84, 1169–1175.

[16] Tambunan, A.H., Situmorang, J.P., Silip, J.J., Joelianingsih, A.,

Araki, T., Yield and physicochemical properties of mechanically extracted crude Jatropha curcas L oil, Biomass and Bioenergy 43 (2012) 12-17