ICR07-B2-1565

Controlling a 2-phase CO

2loop using a 2-phase accumulator

Bart VERLAATNational Institute for Nuclear Physics and High Energy Physics (NIKHEF) P.O. Box 41882, 1009 DB, Amsterdam, the Netherlands

Email: bverlaat@nikhef.nl

Telephone: +31 20 592 2095/ Fax: +31 20 592 5155

ABSTRACT

Mechanically pumped 2-phase fluid loops often have the problem of insufficient sub-cooling to operate the pumps without cavitation. This paper describes the use of 2-phase accumulators for controlling CO2 loops to obtain forced

sub-cooling and accurate evaporator control. The technique of using 2-phase accumulators for loop control was first applied in satellite cooling.

Two accumulator controlled loops have been successfully developed at NIKHEF. One CO2 loop for cooling the AMS

particle detector which will study cosmic radiation onboard the International Space Station and a second CO2 loop is

developed for cooling the LHCb-VELO particle detector which will study CP-violation at the CERN laboratory in Geneva (Switzerland).

A 2-phase accumulator has the advantage of controlling the evaporator and condenser pressures independent of the primary cooler temperature. It is therefore possible to create as much sub-cooling for the pump as desired. It is even possible to operate the loop in single phase, a feature which turns out to be very convenient during start-up and cooling-down procedures. A 2-phase accumulator for evaporator pressure control in combination with an internal heat exchanger between the liquid feed and the 2-phase return line creates a very stable evaporator with a guaranteed evaporation at low vapor qualities. In this way the evaporator heat transfer can be tuned and evaporator dry-out is prevented.

1. INTRODUCTION

The semiconductor silicon tracking detectors of the Alpha Magnetic Spectrometer (AMS) (Borgia, 2005)on the

International Space Station (ISS)and the LHCb-VErtex LOcator Experiment (VELO)(LHCb collaboration, 2001) at the CERN’s Large Hadron Collider (LHC) require accurate thermal control of the silicon sensors. The readout electronics of the sensors produce the heat which a cooling system should remove. Construction material used inside silicon detectors must be of low mass and tolerant to ionizing radiation. To suppress radiation damage of the silicon detectors, the silicon must be kept cold to sub-zero temperatures at all times (Rose collaboration, 1999). A silicon tracking detector consists of multiple silicon sensors which are uniformly spread over the detector volume. All the silicon sensors need to have equal temperatures within 1 or 2 degrees to avoid thermal stresses. The discussed requirements for a silicon detector cooling system such as: low mass, multiple heat sources, small temperature gradients and radiation resistance, give design constraints to the cooling system which are different from conventional cooling systems.

The requirements of the cooling system for the LHCb VELO detector have led to the use of CO2

as evaporative cooling fluid (Boer Rookhuizen et al. 1999). CO2 was selected as coolant because of

the radiation hardness and the proper 2-phase temperature range. Feasibility tests have shown excellent thermal performance of CO2 in small

diameter evaporators, which is a welcome feature for a cooling system were low mass is required. The development of CO2 evaporative cooling at

NIKHEF was simultaneous to the developments of CO2 cooling in the commercial refrigeration

industry.

The AMS Silicon Tracker required a cooling system which can keep the evaporator section at a constant temperature. In space the background temperature is around 4 Kelvin, heat can be rejected to space from radiator panels. These radiators have a fluctuating temperature due to the changing exposure to the sun and earth.

At NIKHEF a mechanically pumped CO2 loop was developed for the cooling of the AMS Silicon Tracker. This cooling

system is named AMS-Tracker Thermal Control System (AMS-TTCS), (Verlaat et al. , 2002). The temperature in the evaporator is controlled by a 2-phase accumulator control mechanism which is used in capillary pumped loop systems, which were under development for satellite cooling (TPX Space Shuttle experiment), (Delil, et al. 1997). The 2-phase accumulator keeps the pumped loop at a constant system pressure. The evaporator temperature is therefore fixed, as long as saturated liquid is flowing through it. The temperature variation in the sub-cooled liquid from the condenser is heated by the internal heat exchanger. In this way it is possible to keep the evaporator constant at a fluctuating heat sink, without additional heating or mechanical control. This is important in space, because power is limited and mechanical actuators have a too large risk of failure.

The method of controlling a 2-phase loop with a 2-phase accumulator as it was done in the AMS-TTCS is well suited for the use in the cooling cycle of the LHCb-VELO detector. This cooling system is named VELO Thermal Control System (VTCS) (Verlaat, 2005). The cold radiator of the AMS-TTCS is replaced by a conventional refrigeration system. This combination allows temperature control of the VELO detector at a large distance (~50m), without any control actuators in the radiation area, resulting in a complete passive evaporator system. This paper describes the design and testing of a 2-phase accumulator controlled loop (2PACL) developed for the VELO Thermal Control System.

Figure 1.1: The AMS experiment on the ISS

27 VELO modules Evaporator with 27

parallel connections

Figure 1.2: The LHCb VErtex LOcator

2. THE 2-PHASE ACCUMULATOR CONTROLLED LOOP FOR THE VTCS

2.1 PRINCIPLE OF A 2-PHASE ACCUMULATOR CONTROLLED LOOP (2PACL)Figure 2.1 shows the schematic diagram of the 2PACL as it is applied in the VELO. A mechanically pumped CO2 loop

is cooling the VELO detector by evaporating low quality CO2 (9-10). The vapor is condensed by a chiller with R404a

as refrigerant (13-1). The condensed liquid is pumped by a liquid pump back towards the detector (2-3-8). The evaporator and condenser work at the same pressure, because the pressure drop of the vapor return line is low. The CO2

pressure is controlled by the 2-phase accumulator (14) which is parallel connected between the condenser and the pump (1). The accumulator contains a saturated CO2 liquid-vapor mixture. The temperature of the saturated mixture in the

accumulator is regulated, controlling the accumulator pressure hence the condenser and evaporator pressure. The pressure regulation of the accumulator is a combination of heating and cooling. An electrical heater is evaporating liquid CO2 causing the pressure to increase, an evaporator branch of the primary R404a chiller is condensing CO2 vapor

causing the pressure to decrease.

In order to ensure sub-cooling of the CO2

before the liquid pump, the accumulator temperature must be above the condenser temperature. The sub-cooled state will prevent the pump from cavitation, a common problem in mechanically pumped 2-phase loops. The sub-cooled liquid is however too cold to be injected into the evaporator, because evaporators require saturated liquid. To heat the liquid up to saturation, a heat exchanger between the liquid inlet (4-5) and vapor outlet (11-12) of the evaporator is used. The absorbed heat in the evaporator is used to heat the sub-cooled flow so no extra heat is needed. Figure 2.2 shows the schematic of figure 2-phase gas R404a chiller 1 2-phase 2-phase liquid 2-phase Condenser Evaporator Concentric tube Pump Restriction Accumulator liquid 2 3 4 10 9 8 7 6 5 11 12 14 13 2-phase gas Transfer lines (Ca. 50m)

Cooling plant area VELO area Inside VELO

Heater 2-phase gas R404a chiller 1 1 2-phase 2-phase liquid 2-phase Condenser Evaporator Concentric tube Pump Restriction Accumulator liquid 2 2 3 3 44 10 10 9 9 8 8 7 7 6 6 5 5 11 11 12 12 14 14 13 13 2-phase gas Transfer lines (Ca. 50m)

Cooling plant area VELO area Inside VELO

Heater

Figure 2.1: Schematic of the VELO Thermal Control System

Figure 2.2: Operation of a 2PACL in the P-h diagram of CO2

-450 -400 -350 -300 -250 -200 -150 5x 102 103 104 2x 104 h [kJ/kg] P [kPa] -40°C -30°C -20°C -10°C 0°C 10°C 0.2 0.4 0.6 Te rtia ry V TCS in P -H dia gr am 1 2 3 4 5 6 7 Accumulator pressure = detector temperature

Internal heat exchanger brings evaporator pre-expansion per definition right above saturation

(3-5)=-(10-13) Saturation line

Capillary expansion brings evaporator in saturation Detector load (9-10) 10 13 9 8 5 3 1

Pump is sub cooled

-450 -400 -350 -300 -250 -200 -150 5x 102 103 104 2x 104 h [kJ/kg] P [kPa] -40°C -30°C -20°C -10°C 0°C 10°C 0.2 0.4 0.6 Te rtia ry V TCS in P -H dia gr am 1 2 3 4 5 6 7 -450 -400 -350 -300 -250 -200 -150 5x 102 103 104 2x 104 h [kJ/kg] P [kPa] -40°C -30°C -20°C -10°C 0°C 10°C 0.2 0.4 0.6 Te rtia ry V TCS in P -H dia gr am 1 2 3 4 5 6 7 Accumulator pressure = detector temperature

Internal heat exchanger brings evaporator pre-expansion per definition right above saturation

(3-5)=-(10-13) Saturation line

Capillary expansion brings evaporator in saturation Detector load (9-10) 10 13 9 8 5 3 1

2.1 in the P-h diagram of CO2. The indices of the diagram correspond to the nodes in figure 2.1. The exchanged heat in

the internal heat exchanger is the enthalpy difference of node 3 and 5. As a minimum this heat must have been absorbed in the evaporator (9-10). If the evaporated heat is sufficient to overcome the sub-cooling, the evaporator inlet (Node 9) is 2-phase and close to the saturated liquid curve, otherwise the inlet of evaporator remains sub-cooled causing degraded heat transfer.

A 2PACL does only require a controlled accumulator. The 2PACL condenser temperature may vary, as long as the maximum temperature is lower than the accumulator set-point. The chiller may therefore run maximal cold, without any chiller evaporator regulation. The 2PACL pump flow may be constant as well; a sufficient overflow of the pump will make the system heat load independent and prevent the 2PACL against evaporator dry-out.

A useful feature of the 2PACL is the ability of turning the 2-phase loop into a single phase loop. Significantly increasing the accumulator’s pressure will suppress any formation of vapor anywhere in the loop. This feature is very useful at start-up. It is used as start-up procedure in both the AMS-TTCS and the LHCb-VTCS systems.

2.2 VELO THERMAL CONTROL SYSTEM DESIGN.

The cooling plant contains the chillers, the pumps, the accumulators and valves. The detector with evaporator is away from the cooling plant and situated in a hostile radiation environment which makes it inaccessible. The transfer of cooling fluid from the plant to the evaporator is via a concentric transfer tube. The liquid feed line is inside the vapor return line and bridges the 50 meter distance from the plant to the evaporator. The transfer tube is concentric so the environmental heat will only affect the return flow. The concentric tube is the necessary internal heat exchanger to overcome liquid sub-cooling.

The silicon wafers in the detector need to be kept cold at all times. This is also required even if the detector is switched off. In paragraph 2.1 it was discussed that a heat load is needed in the evaporator to overcome the sub-cooling. If no sufficient heat load is available, sub-cooled liquid will enter the evaporator and the accumulator is no longer able to control the temperature of evaporator. The evaporator can become colder than the accumulator set-point leading to an uncontrolled and too cold detector. The

transfer tube’s isolation is tuned such that enough heat from the environment is entering the loop at all time to overcome the sub-cooling, the evaporator does not need a heat load in this case. The concept of environmental heat leak is chosen over electrical heating, because of reliability issues.

The evaporator has flow restrictions to distribute the flow evenly over the 27 parallel cooling connections. At start-up these restrictions can cause large pressure drops in the system when vapor has to pass through. At start-up it is also not guaranteed that the pumps are primed with liquid. The pumps are not self priming and they will not start up if there is no

Figure 2.3:VTCS CO2 plant

liquid inside. A nice feature of the accumulator control is that the 2-phase loop can be turned into a single phase liquid loop by heating-up the accumulator. The VTCS-accumulator will be heated to 27ºC prior to start-up. The pressure in the loop is above the saturation pressure of the environment, causing the CO2 in the loop to be liquefied. The pump can

now start-up without problems and the restrictors are fed with liquid, keeping the pump head pressure low.

2.3 VTCS SIMULATION RESULTS.

A simulation model of the VTCS loop has been made to study the thermal equilibriums of the different operational states in transient modes. Figure 2.5 shows the simulation results of several situations from start-up to cold operation. The model calculates the energy and pressure balance of the nodes of figure 2.1. Environmental heat leak is included and calculated between each node. Prior to start-up, the whole loop is at room temperature. It is not defined where the liquid or vapor is situated. The start-up situation (A) in the P-h diagram is somewhere along the 20ºC isotherm in the 2-phase region. At start up the accumulator is heated to 27ºC and the system pressure increases to the corresponding saturation pressure of 67 bar. The loop is still at room temperature and will be filled with liquid. Once the loop is filled, the pump can be switched on. Sub-cooled liquid of 20ºC is now circulated and cooling from the primary R404a chiller is not yet needed. The loop operates as situation “B” in the P-h diagram. Once liquid circulation is achieved the primary chiller can be switched on. The accumulator is kept at high pressure so all the liquid will stay sub-cooled. In paragraph 2.1 it was discussed that the primary R404a chiller does not need any temperature regulation, therefore it will cool the liquid flow to its minimum temperature. After cooling down in liquid mode the situation of “C” has been reached. The pump flow will be about -40ºC, the evaporator (with liquid only!) is about -22ºC. The thermal gradient is due to the heat leak of the transfer tube. After having cooled down the loop in liquid mode, the accumulator can be cooled down by the primary chiller to the desired set-point of -30ºC. The system is now at situation “D”, which is indicated by the small squares in figure 2.5. The unloaded evaporator (node 9-10) is now in the 2-phase region, so its temperature is now controlled by the accumulator.

Once the situation of “D” is stabilized, the detector power is switched on. In the diagram this means that node 10 is moved away from node 9, ending up in situation “E”. The circuit of “E” also shows a change of the sub-cooled temperature of node 1 with respect to situation “D”. This increase is due to the behavior of the primary R404a chiller. An increased heat load causes the compressor suction pressure to increase, and hence the primary evaporator pressure and temperature.

The simulation clearly shows the

independence of a varying sub-cooling. As long as node 1 is on the left of the saturation line, the system works properly. The inlet of the evaporator (node 9) is controlled to stay 2-phase and near the saturation line, assuring the evaporator being fed with a low quality 2-phase flow.

5 0 1 0 0 1 5 0 2 0 0 2 5 0 3 0 0 3 5 0 4 0 0 5 x1 00 1 01 1 02 2 x1 02 h [kJ/kg] P [bar] -40°C -20°C 0°C 20°C 40°C 0.2 0.4 0.6 0.8

VTCS sta rt -up and o pe r atin g cycle s

1 3,5 8 10,13 1 3 5 8 9,10,13 1 3 5 8 9,10 13 1 3 5 8 9 1 0 1 3 C B D E A 5 0 1 0 0 1 5 0 2 0 0 2 5 0 3 0 0 3 5 0 4 0 0 5 x1 00 1 01 1 02 2 x1 02 h [kJ/kg] P [bar] -40°C -20°C 0°C 20°C 40°C 0.2 0.4 0.6 0.8

VTCS sta rt -up and o pe r atin g cycle s

1 3,5 8 10,13 1 3 5 8 9,10,13 1 3 5 8 9,10 13 1 3 5 8 9 1 0 1 3 C B D E A

2.4 VTCS ACCUMULATOR DESIGN

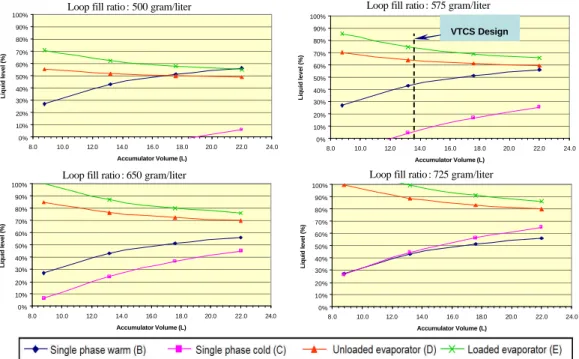

The accumulator must be partially filled with liquid at all operational situations. Figure 2.6 show the simulation results of different liquid fillings in the accumulator as a function of accumulator volume for several fill ratios of the accumulator and loop together. It shows that the 2 extreme accumulator liquid levels appear at the single phase cold (C) for the minimum level and the loaded evaporator (E) for the maximum level (C and E are the situations of figure 2.5). The chosen VTCS design parameters are indicated in the 2nd graph by a vertical dashed line; for a VTCS loop volume of 8.8 liter a fill ratio of 575 gram per liter with an accumulator volume of 13.6 liter are sufficient to comply with all the operational scenarios.

Figure 2.6: Accumulator liquid levels as a function of accumulator volume and fill ratios for a loop volume of 8.8 liter. 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0 Accumulator Volume (L) Liquid level (%) . 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0 Accumulator Volume (L) Liquid level (%) . 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0 Accumulator Volume (L) Liquid level (%) . 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% 8.0 10.0 12.0 14.0 16.0 18.0 20.0 22.0 24.0 Accumulator Volume (L) Liquid level (%) . VTCS Design

Loop fill ratio : 500 gram/liter

Loop fill ratio : 650 gram/liter Loop fill ratio : 725 gram/liter

Figure 2.9: Accumulator cooling coils Figure 2.8: Thermo siphon

heater Figure 2.7: Accumulators in

the VTCS plant

Figure 2.10 shows the mechanical design of the VTCS accumulator. The heater must be submerged in the liquid to avoid partial dry-out. In practice this means that the heater needs to stay below the minimum level of situation “C” at the design parameter line of figure 2.6. The capacity of the heater is driven by the required speed of pressurizing. A rod element heater of 1 kW was chosen. The heater is at the bottom of the accumulator in a concentric thermo-siphon lay-out. The evaporated CO2 on the

heater surface is going up, sucking new liquid via the outer annulus to the heater. Care must be taken at heating near the critical point of CO2. The difference

in the density of liquid and vapor becomes small, decreasing the liquid flow. The decreased liquid flow causes a dry-out with high heater temperatures as a result.

A lowering of the system pressure is achieved by condensing the vapor content in the accumulator. In the VTCS accumulator this is achieved with a coiled tube inside the accumulator volume (figure 2.9). The coil is cooled with R404a by the primary chiller. This coil is situated at the upper part of the accumulator. A large part of the coil needs to be above the maximum level of situation “E” at the design parameter line of figure 2.6. A submerged part of the spiral is no problem, it only decreases the condensation surface and hence the cooling down speed. At the VTCS the liquid level is monitored using a dielectric probe.

2.5 VTCS TEST RESULTS.

Figure 2.11 shows some test results of the VTCS test system. The loop was started up from stand still to cold operation. Time “A” was the start-up time. The loop was still cold from earlier tests. The saturation temperature of the loop was 10ºC, while the pump was at room temperature. The pump was filled with vapor only and could not start-up. The accumulator was heated to pressurize the system such that the saturation temperature of the system became above room temperature. At time “B” the accumulator heater was reduced to avoid heater dry-out; pressurization is now going slower. At time “C” the system was sufficiently filled with

-40 -30 -20 -10 0 10 20 30 40 50 60 6:21:36 6:50:24 7:19:12 7:48:00 8:16:48 8:45:36 9:14:24 Time (hh:mm:ss)

Temperature (ºC), Pump flow (g/s) .

-30 -20 -10 0 10 20 30 40 50 60 70 Pressure (Bar) Pump liquid (ºC)

Evaporator Saturation Temperature (ºC) Evaporator Temperature (ºC) Massflow (g/s) Accu Pressure (Bar) Evaporator Pressure (Bar)

A B C D E F G H -40 -30 -20 -10 0 10 20 30 40 50 60 6:21:36 6:50:24 7:19:12 7:48:00 8:16:48 8:45:36 9:14:24 Time (hh:mm:ss)

Temperature (ºC), Pump flow (g/s) .

-30 -20 -10 0 10 20 30 40 50 60 70 Pressure (Bar) Pump liquid (ºC)

Evaporator Saturation Temperature (ºC) Evaporator Temperature (ºC) Massflow (g/s) Accu Pressure (Bar) Evaporator Pressure (Bar)

A B C

D E

F G H

Figure 2.11: VTCS Test results Figure 2.10: VTCS Accumulator mechanical design

liquid so the pump could start-up. The pump was rapidly cooling down while the evaporator temperature was staying behind. The accumulator was maintained on pressure making the system cooling down in sub-cooled liquid state. At time “D” the accumulator cooling started at a set-point of -25ºC. At time “E”, the evaporator was no longer sub-cooled; the accumulator had taken over control of the evaporator’s temperature. At time “F”, the evaporator had reached the set-point temperature of -25ºC and the detector power was switched on. At time “G” the accumulator set-point was lowered to -30ºC, reaching the -30ºC evaporator temperature at time “H”. This was the minimum reachable evaporator temperature with the VTCS test system, because the pump sub-cooling had become marginal. Note that the accumulator and evaporator pressures were the same during the entire test.

3. CONCLUSION AND DISCUSSION

The 2-phase accumulator controlled loop (2PACL) method is a good solution for controlling mechanically pumped 2-phase loops. It can operate at a large dynamic evaporator pressure range and is virtually independent of heat load and condenser temperature. The accumulator pressure is the only accurate controlled parameter in the system. This makes the system robust, stable and easy to operate.

The 2PACL method is a good alternative for controlling the current secondary pumped loops. The accumulator method can also be used for 2-phase loop systems which do not need controlled evaporators but only need to transfer heat from A to B. One can think of an accumulator maintaining a slight over-pressure with respect to the pump sub-cooling, just enough to avoid pump cavitation. Different types of accumulators can be considered, such as a spring acted bellow accumulator with secondary 2-phase loading at the loop temperature, or an accumulator with a secondary fluid mixture having slight over pressure properties to the loops working fluid. An active pneumatic controlled accumulator is also an option. The LHCb-VTCS and the AMS-TTCS both use CO2 as working fluid, but the principle is expected to work

for any 2-phase fluid pumped systems.

4. REFERENCES

1. B.Borgia, 2005, The Alpha Magnetic Spectrometer on the International Space Station, IEEE Transactions on Nuclear Science, Vol. 52, No. 6, p. 2786-2792

2. The LHCb Collaboration, 2001, The LHCb VELO Technical Design Report, CERN/LHCC note, 2001-0011

3. The ROSE Collaboration, 1999, R&D On Silicon for future Experiments, CERN/LHCC note, 2000-009

4. Boer Rookhuizen H. et al, 1999, Preliminary Studies for the LHCb Vertex Detector Cooling System, LHCb note, 99-046/VELO

5. Verlaat, B., Krijger, E., 2001, Performance Testing of the AMS TTCS CO2 Evaporator., NIKHEF note, ASR-T-

001/MT 01-02.

6. Verlaat, B. et al. 2002, Feasibility Demonstration of a Mechanically Pumped Two-Phase CO2 Cooling Loop for

the AMS-2 Tracker Experiment, Conference on Thermophysics in Microgravity, in the Space Technology & Applications International Forum (STAIF-2002), Albuquerque, NM, USA

7. Delil, A.A.M. et al., 1997, In-orbit demonstration of two-phase heat transport technology - TPX II reflight,

European Space Agency, SP-400, p.355

8. Verlaat, B., Woering, A., Pauw, A., Delil, A.A.M., 2003, AMS-2 Tracker Thermal Control System: design and thermal modeling of the mechanically pumped two-phase CO2 loop, AIAA Aerospace Sciences Meeting & Exhibit,

Reno, NV, USA, (AIAA-2003-0345)

9. Verlaat, B., 2003, Thermal Performance Testing of the VTCS Evaporator and VELO Module, NIKHEF note, MT