Effect of Fiber Length on the Mechanical

Properties of Coir and Wild Date Palm

Reinforced Epoxy Composites

Sharath G P Kishor B S

Student Student

Department of MechanicalEngineering Department of MechanicalEngineering Vidyavardhaka college of Engg. Mysuru, 570002 India Vidyavardhaka college of Engg. Mysuru, 570002 India

Vinod B Naveen Ankegowda

Assistant Professor Assistant Professor

Department of MechanicalEngineering Department of MechanicalEngineering Vidyavardhaka college of Engg. Mysuru, 570002 India Vidyavardhaka college of Engg. Mysuru, 570002 India

Abstract

Now day’s natural fibers as reinforcement have received more attention from the research community all over the world in preparing polymer composites. These natural fibers have lot of advantages over synthetic fibers. In this paper two natural fibers wild date palm and coir reinforced composites were fabricated using hand lay-up method which was a new effort and was not done elsewhere. Specimens were cut from the fabricated composite plates according to the ASTM standards. Universal Testing Machine was used for testing tensile and flexural strength of the composites. The impact strength of the composites was analyzed using Impact tester. Fiber length of 3mm, 6mm, 9mm, 12mm & 15mm was subjected to analysis. A higher tensile strength of 26.27Mpa and flexural strength of 67.35MPa was obtained for the fiber of length 12mm compared to the fiber length of 3, 6, 9 and 15mm. The Higher impact strength of 6.41 KJ/m2 was obtained for fiber of length 15mm. From this experimental study, it was observed that the fiber length greatly influences the tensile properties of reinforced composites.

Keywords: Natural fibers (coir and wild date palm), Epoxy, Tensile Strength, Flexural Strength, Impact Strength

________________________________________________________________________________________________________

I. INTRODUCTION

The interest in using natural fibres such as different plant fibres and wood fibres as reinforcement in plastics has increased dramatically during last few years. With regard to the surrounding aspects it would be very interesting if natural fibres could be used instead of glass fibres as reinforcement in some structural applications. Natural fibres have many advantages compared to glass fibres, for example they have low density, and they are recyclable and biodegradable. Additionally they are renewable raw materials and have relatively high strength and stiffness. Their low-density values allow producing composites that combine good mechanical properties with a low specific mass.

Natural fibers are classified on the basis of the origin of source, into three types 1) Plant Fibers

2) Mineral Fibers 3) Animal Fibers

Plant Fibers:

Generally plant fibers contain cellulose: examples such as cotton, pineapple, Jute, flax, banana, ramie, Sisal. Paper and cloth are manufactured by cellulose fiber. Skin fibers are the fibers are collected from the skin of the stem of their own plant. They have superior tensile strength than the other fibers.

Mineral Fibers:

Mineral fibers are obtained in nature and they are mainly tough because of less number of face defects. Asbestos is a commonly obtained natural mineral fiber. It includes wood, Quartz, and glass, A1 oxide, and silicon carbide.

Animal Fibers:

II. MATERIALS AND METHODOLOGY

Materials

Coir is a natural fiber extracted from the husk of coconut and used in products such as floor mats, doormats, brushes, mattresses, etc. Coir is the fibrous material found between the hard, internal shell and the outer coat of a coconut. Other uses of brown coir in upholstery, padding, sacking and horticulture. White coir, harvested from unripe coconuts, is used for making finer brushes, strings, rope and fishing nets. Table 1 shows physical and mechanical properties of coir fiber.

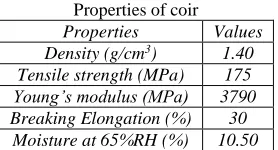

Table 1: Properties of coir

Properties Values

Density (g/cm3) 1.40 Tensile strength (MPa) 175 Young’s modulus (MPa) 3790 Breaking Elongation (%) 30

Moisture at 65%RH (%) 10.50

The wild date palm is a mono cotyledon of the family of the palmate. It is a feather palm, characterized by compound leaves with a series of leaflets on each side of a common petiole, originating from one growing point at the top of the trunk. The date palm may reach an age of over 100 years and reach up to 24m in height. Table 2 shows physical and mechanical properties of wild date palm fiber.

Table 2:

Properties of Wild Date Palm

Property Values

Density (g/cm3) 1-1.20 Tensile strength (MPa) 97-196 Young’s modulus (MPa) 2500-5400

Breaking Elongation (%) 2-4.5

Lapox L12 is a liquid, unmodified epoxy resin of medium viscosity which can be used with various hardeners for making glass fiber reinforced composite. The choice of hardener depends on the processing method to be used and on the properties required of the cured composite. Table 3 shows the properties of Lapox L12 resin.

Table 3: Properties of Lapox L12

Property Values

Tensile strength (MPa) 19 Flexural strength (MPa) 130-150

Impact strength (MPa) 17-20 Young’s modulus (MPa) 4400-4600 Compressive strength (MPa) 110-120

Methodology

Extraction of fibers:

The coir and wild date palm fiber is obtained from coir and wild date palm plant, which has been collected from local sources. The extracted coir and wild date palm fiber were subsequently sun dried for 8 hours to remove free water present in the fiber.

Chemical treatment:

Alkali treatment or mercerization using sodium hydroxide (NaOH) is the most commonly used treatment for bleaching and cleaning the surface of natural fibers to produce high-quality fibers. Modifying natural fibers with alkali has greatly improved the mechanical properties of the resultant composites. The following steps were carried out during chemical treatment.

5% NaOH solution was prepared using sodium hydroxide pellets and distilled water. Coir and wild date palm fibers were then dipped in the solution for 1hour.

After 1 hour fibers were washed with 1% HCL solution to neutralize the fibers. Then it is washed with distilled water.

It was then kept in hot air oven for 3 hours at 65-700C.

Manufacturing of composite:

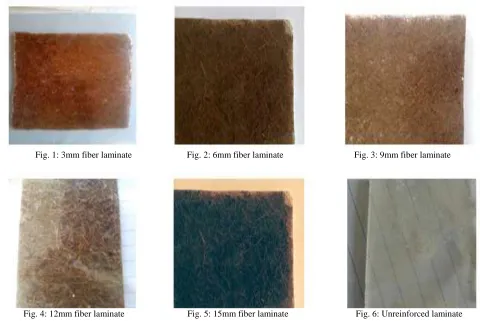

Fig. 1: 3mm fiber laminate Fig. 2: 6mm fiber laminate Fig. 3: 9mm fiber laminate

Fig. 4: 12mm fiber laminate Fig. 5: 15mm fiber laminate Fig. 6: Unreinforced laminate

III. RESULTS AND DISCUSSION

Tensile Test:

The tensile test was conducted following the standard of ASTM D638 (150*20*4mm) type IV using JJ Lloyd universal testing machine with load cell of 1KN and using crosshead speed of 5 mm/min. The test was performed until the tensile failure occurred. Figure 8 shows the Variation of Tensile strength for coir and wild date palm reinforced laminated composites with fiber length of 3, 6, 9, 12 and 15mm. From table 4 it can be observed that a slight increase of 3.94% for 3mm fiber length compared to unreinforced polymer composites. But the value increased significantly by 24.87% for 12mm fiber length and it was the highest than 3, 6, 9 and 15mm fiber length. The highest value tensile strength is 27.22MPa is obtained for laminated composite of fiber length 12mm.

Table 4: Tensile test results Fiber length

(mm) Maximum load(KN) Young’s modulus(MPa) Stress at maximum load(MPa)

3 1.27 3807.19 21.29

6 1.38 4719.11 23.12

9 1.49 6325.12 24.98

12 1.63 5996.42 27.22

15 1.51 5630.2 25.86

Fig. 7: Specimen undergoing tensile test Fig. 8: Variation of Tensile strength with fiber length

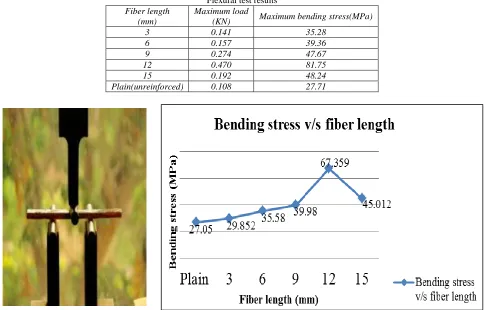

Flexural Test:

Here ASTM standard D790 (80*10*4mm) is used. Three-point loading system applied on a supported beam was utilized. The flexural test was conducted using JJ Lloyd universal testing machine with load cell of 1KN and using crosshead speed of 5mm/min. Test was performed until flexural failure occurred.

Figure 10 shows the Variation of bending strength for the coir and wild date palm reinforced laminated composites with fiber length of 3, 6, 9, 12 and 15mm. From table 5 it can be seen that the highest value of maximum bending stress is 81.75 MPa for 12mm which is 66.1% greater than the matrix material. Finally, there was a decrease in its value for 15mm fiber length but it was 42.55% greater than that of unreinforced polymer composite.

Table 5: Flexural test results Fiber length

(mm)

Maximum load

(KN) Maximum bending stress(MPa)

3 0.141 35.28

6 0.157 39.36

9 0.274 47.67

12 0.470 81.75

15 0.192 48.24

Plain(unreinforced) 0.108 27.71

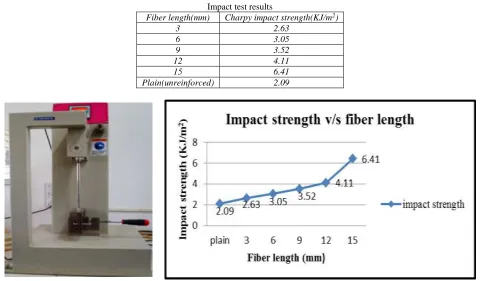

Impact test:

The impact properties of the material are directly related to the overall toughness which is defined as the ability to absorb applied energy. Impact strength is a measure of toughness. Charpy impact test was carried out on a test specimen as per ASTM standard D256 (80*10*4mm).

The table 6 shows that the highest value of Charpy impact strength is 6.41KJ/m2 for 15mm fiber length which is 67.39% greater

than the matrix material Lapox L12. Initially for fiber length of 3mm impact strength increased by 22.3%.as the length fiber length increased from 3mm to 6mm a tremendous increase from 2.09KJ/m2 to 3.05KJ/m2 was observed ( a 31.47% increases). Then its

value increased by 40.62% for 9mm and 49.14% for 12mm fiber. Figure 12 shows the Variation of Impact strength with fiber length

Table 6: Impact test results

Fiber length(mm) Charpy impact strength(KJ/m2)

3 2.63

6 3.05

9 3.52

12 4.11

15 6.41

Plain(unreinforced) 2.09

Fig. 11: Specimen undergoing impact test Fig. 12: Variation of Impact strength with fiber length

IV. CONCLUSION

The results of this present study showed that a useful composite with good properties could be successfully developed using treated coir and wild date palm as reinforcing agent for the Lapox L12 matrix. It can be seen that composites reinforced with fiber length of 12mm show better tensile strength of 27.22MPa and flexural strength of 81.75MPa than 3mm, 6mm, 9mm and 15mm length. But better impact strength of 6.41 KJ/m2 was obtained for fiber length of 15mm than 3mm, 6mm, 9mm and 12mm reinforced composites. Hence fiber length greatly influences the mechanical properties of the coir and wild date palm reinforced Lapox L12 composite.

REFERENCES

[1] Vinod B, Dr Sudev L J , Effect of fiber orientation on the Flexural properties of PALF Reinforced Bisphenol Composites: International Journal of Science and Engineering Applications Volume 2 Issue 8, ISSN-2319-7560, 2013. [7] J George, S S Bhagwan.

[2] Rajendra Prasad Verma, Vinod Kumar Verma and Ajeet Kumar Rai, Study of Mechanical Properties of Natural Fibre Composite,International Journal of Design and Manufacturing Technology (IJDMT), Volume 7, Issue 1, January-April 2016, pp. 01-06.

[3] Santosh Kumar D S, Praveen B A, Kiran Aithal S, U N Kempaiah, Development of pineapple leaf fiber reinforcing epoxy resin composites. International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056 Volume: 02 Issue: 03 | June-2015

[4] Dr. Navdeep Malhotra1, Khalid Sheikh2 and Dr. Sona Rani, A Review on Mechanical Characterization of natural fiber reinforced polymer Composites, Journal of Engineering Research and Studies E-ISSN0976-7916