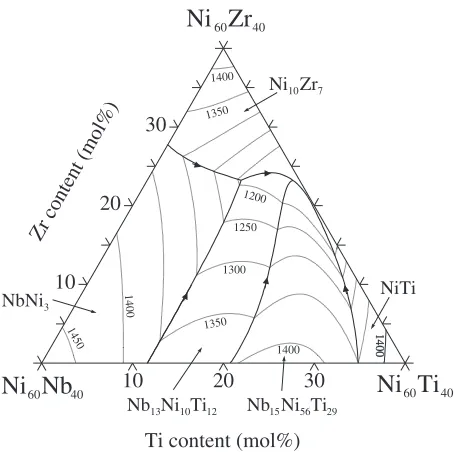

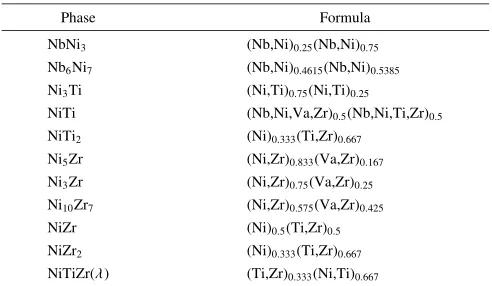

Thermodynamic Calculation of Phase Equilibria in the Nb Ni Ti Zr Quaternary System

Full text

Figure

Related documents

s in Ti-Nb alloys have been studied experimentally. M s decreases with increasing Zr 11,21) content in the Ti-Nb alloys. In the experimental works, the Nb concentration range has

In our previous study, we investigated the oxidation behav- ior and phase equilibrium of Ti-Al-Sn-Nb quaternary alloys 8). We found that the mass change during isothermal oxidation

A. The replacement of Zr by a small amount of Ti and Nb caused a distinct increase in the maximum diameter from 16 mm for Zr 65 Al 7 : 5 Ni 10 Cu 17 : 5 to 20 mm, accompanying

The thermodynamic analysis of this binary system was performed based on the experimental information above, as well as the calculated enthalpy of formation for the three types of

Recently, one of the authors found out that the Nb-Ti-Ni alloy consists of bcc-(Nb, Ti) + B2-TiNi eutectic micro- structures with an appropriate combination of

3.1 The maximum cold-rolling reduction rate, crystal structures, microstructures and hydrogen perme- ability for the as cast Nb 40 (Ti 30 x Zr x )Ni 30 alloys Figure 1 shows a

Figure 9 shows stress-strain curve obtained by tensile test up to fracture of each Ti-Nb-Ta-Zr system alloy. Each stress- strain curve shows different shape. In particular, it is

Figure 9 shows the compressive stress-elongation curves of some Cu–Zr–Ti–Ni–Nb bulk glassy alloy rods.. In addition, one can see distinct plastic elongation of 0.2 to 0.8%.