SUSTAINING SUPPLY CHAIN INTEGRATION THROUGH

PERFORMANCE MEASUREMENT SYSTEM: AN

INTEGRATED APPROACH

Abirami Radhakrishnan1, V “Sri” Sridharan2,**, and Douglas N. Hales3 1

Department of Information Sciences and Systems, 507 MM Hall, Morgan State University, Baltimore, MD 21251, USA, Phone: (443) 885-1695, E-mail: aradhak@gmail.com 2

EM-Lyon, 23 Ave Guy de Collangue, Ecully, 69130, France, Phone: 04 72 18 46 44 E-mail:

sridharan@em-lyon.com 3

College of Business Administration, Ballentine Hall, University of Rhode Island, 7 Lippitt Road, Kingston, RI 02881, USA, Phone: (401) 874-7882, Email: dhales@uri.edu

** Corresponding Author

Abstract: Supply Chain Integration is advocated as one of the important factors to attain superior

supply chain performance. Supply chain integration is not a one-time accomplishment. Sustaining supply chain integration is just as important. In order to sustain supply chain integration, supply chain-wide performance measurement system is needed. We draw on theories from a number of management disciplines to derive a set of research propositions for developing supply chain performance measurement systems.Key Words: Supply Chain Management, Supply Chain Integration, Supply Chain Collaboration; Metrics & Performance Measurement, Supply Chain Performance Management

1

Introduction

One of the important challenges facing firms is the need to integrate internal functions as well as the entire supply chain. The importance of Supply Chain Integration (SCI), which is a state of achieving both internal and external integration, can be found in the literature. SCI can help firms achieve superior performance. Growing evidence suggests that higher the degree of SCI achieved by the firm, the greater the potential benefits (Stevens, 1990; Frohlich and Westbrook, 2001; Rosenzweig, et al., 2003; Droge, et al., 2004). These studies, however, examined how SCI affect the performance of an individual firm rather than the performance of the supply chain as a whole.

Despite positive results in the relationship between SCI and the focal firm level performance, another stream of research points out that many firms that successfully implement SCI in the beginning are not able to sustain integration in a long run (Holmberg, 2000; Lapide, 2000; Lambert and Pohlen, 2001; Moberg and Speh, 2003; Lee, 2004). The deterioration of supply chain integration results in a tremendous waste of financial and temporal resources and, consequently, harms the ability of the supply chain to compete over the long term. It appears that the major impediment to sustaining SCI is lack of system-wide performance measurement system. Aforementioned authors argue that incompatible goals among participants result in local measures designed to optimize the performance of individual firms. Local performance measures cause conflicts among partners, which eventually impede sustaining SCI. To resolve the impediments, researchers recommend developing supply chain-wide performance measurement systems. These systems would help to ensure that metrics are aligned with the goals of the supply chain and are applicable to all partners. Therefore, we argue that consistent supply chain-wide performance measurement system (SCPM) resolves many of the issues that impede supply chain integration.

The purpose of this study is to provide a theoretical basis for developing SCPM in order to sustain SCI. We define a SCPM as a system that includes formal definitions of supply chain measures, measurement procedures, responsibilities and accountability of supply chain partners, and the regulation of the measurement system by supply chain partners. In developing research propositions concerning the effects that SCPM has on sustaining SCI, we draw on theories from a number of management disciplines.

The remainder of this paper is organized into the following sections: a review of the background literature on SCPM and SCI, a theoretical basis for developing SCPM to sustain SCI where we have come out with five research propositions, implications for managers and concluding comments.

2

Review of the background literature

2.1 Supply chain performance measurement (SCPM)

Several researchers have proposed various ways to measure supply chain performance. Beamon (1998) suggested a simple approach to categorize supply chain performance measures into qualitative measures (e.g. customer satisfaction) and quantitative measures (e.g. measures based on cost). She later urged using resource-based measures that are efficiency-oriented and flexibility-based measures that focus on responsiveness (Beamon, 1999). Brewer and Speh (2000) presented a prescriptive framework based on the Balanced Score Card. Gunasekaran et al. (2001) categorized both financial and non-financial measures at strategic, tactical, and operational levels of management, and related these measures to the four links (plan, source, produce, and deliver) of an integrated supply chain. They subsequently rank ordered the relative importance of these metrics using empirical results from 21 British manufacturing firms (Gunasekaran, et al., 2004). Bullinger et al. (2002) proposed a method to combine the SCOR metrics (adapted from SCOR model of the Supply Chain Council) and supply network scorecard metrics into a comprehensive, balanced measurement system. Pohlen (2005) provided an approach to link supply chain metrics to shareholder value.

A careful review of the above studies, leads us to the following two conclusions. First, the scope of the existing studies has been limited to either one dimension of performance (e.g. operational or financial performance) or, when multi-dimensional, just on the focal firm. None focused on a truly multidimensional inter-organizational system. Second, all of these studies discussed specific measures that are neither generalizable nor applicable to all types of supply chains. Moreover, as Lambert and Pohlen (2001) assert, “the goal should not be to identify specific metrics, but to provide a framework that allows management to develop the best performance measures for their situation”. These shortcomings of existing studies serve to highlight the need to develop a supply chain performance measurement system.

2.2 Supply chain integration (SCI)

Supply chain participants seeking integration tend to accomplish it in stages (Aryee, et al., 2005). Stevens (1990) found that participants typically go through four stages in series - baseline, functional, internal, and external – as they progress towards seamless integration. He concluded that the greatest benefits of SCI are realized as firms move towards external integration. In accordance with Stevens’ model we define SCI as follows: SCI is a state of achieving a high degree of both internal integration and external integration. The internal integration is defined as follows: Internal Integration comprises of coordinated cross-functional initiatives by departments or business units within a firm to strengthen the firm’s

value chain. This means that the departments within the firm work jointly in a coordinated manner in order to accomplish the organizational objectives. However, there will be little interface with suppliers and customers. The external integration is defined as follows: External integration comprises of joint initiatives by a firm and its key suppliers / customers to strengthen their value chains. It includes collaboration in the areas of demand forecasting, production planning, product design, development and delivery. By means of internal and external integration, SCI engenders superior supply chain performance. Next, we develop theory concerning the effects that SCPM have on SCI. We integrate multiple theories such as organizational theories and systems theory to develop this model.

3

Theory development – linking SCPM and SCI

Each firm that embarks on SCI moves from one stage of integration to the next. Initially, internal integration occurs through coordinated cross-functional initiatives by departments, functions or business units within the firm that ‘source’, ‘make’, and ‘deliver’ products. Subsequently, external integration occurs by joint initiatives by the firm and its immediate suppliers / customers in several areas such as demand management, demand forecasting, order fulfillment, product design, development, delivery and extends to the entire supply chain. Finally, over time, supply chain participants try to sustain integration.

In Table 1, we summarize the key concepts from goal theory, organization theory, and systems theory to show how key these tenets serve as a basis for understanding the role of a performance measurement system in sustaining integration. In turn, they help explain the effects of SCPM on SCI. The synthesis of the theories leads us to the model presented in this paper. We discuss the various aspects of our model in the following sections.

Theoretical perspective

Key Concepts Application of the key concept

Goal theory Goals regulate human action

(Linderman, et al., 2003)

For facilitating internal integration:

• Performance measurement system and

measures regulated by internal

organizational goals. For facilitating external integration:

• Performance measurement system and measures regulated by mutually agreed supply chain goals.

For sustaining supply chain integration:

• Monitoring and control of SCPM helps in sustaining supply chain integration. Organization

theory

1) Unity of effort between sub systems result in coordination (Lawrence, and Lorsch, 1967) 2) Goal congruence result in greater coordination among units (Emerson, 1962; Pfeffer, and Salancik, 1978)

3) Concept of sequential

interdependency among units and establishment of structure of relationship reduces potential for conflict (Thompson, 1967)

For facilitating internal integration:

• Establishment of business process

orientation (establishment of processes and process measures) to promote greater goal congruence, which in turn would facilitate internal integration. For facilitating external integration:

• Establishment of process based

measurement system at the supply chain level that makes partners jointly accountable and responsible.

• Alignment of the process measurement systems of various partners of supply chain to facilitate external integration.

Systems theory System as an organized unitary whole composed of many sub systems that interact to transform inputs to outputs (Johnson, et al., 1963)

Closed loop system with feedback

subsystem to regulate the

performance of the entire system (Johnson, et al.,1963)

For facilitating external integration:

• SCPM should be viewed as a single system.

For sustaining supply chain integration:

• Regulation of the SCPM to reflect

dynamic changes in external

environment.

• Monitoring and controlling joint

performances of partners to sustain SCI.

Table 1: Theories to explain the role of performance measurement system for sustainable

supply chain integration

3.1 Firm level business process orientation, goal congruence and internal integration

An organization is “a system of interrelated but distinct subsystems (departments or business units) with each subsystem performing a portion of the organizational task, and efforts of each subsystem can be integrated to achieve better organizational performance” (Lawrence and Lorsch, 1967; p. 3). According to the goal oriented approach (Linderman, et al., 2003; p. 193), an organization’s goals, such as higher efficiency and effectiveness, drive and regulate it. Generally, organizational tasks are carried out to accomplish these goals. In practice, however, each department or business unit has its own operative goals. When the goals of individual units are incompatible, the organization as a whole suffers. So, it is imperative that the goals of individual units are congruent. Firms can achieve goal congruence (extent of agreement of the operative goals among departments / business units of the firm) between their departments / subsystems by adopting a business process orientation (Mc Cormack and Johnson, 2001). Davenport (1993) defines business process as a “specific ordering of work activities across time and place, with a beginning, an end, and clearly identified inputs and outputs: a structure for action”. One example of business process is order fulfillment process. Adoption of business process orientation facilitates setting up performance measurement systems with a process focus and helps eliminate hierarchies and functional silos. Greater the degree of adoption of business processes within the firm, greater is the degree of goal congruence.

Adoption of process based performance measurement system also promotes goal congruence. This, however, requires a performance measurement system that takes a systems approach (Holmberg, 2000). Systems approach implies consideration of the system as a whole rather than concentrating on its constituent parts (Johnson, et al., 1963; Checkland, 1993). Accordingly, we argue that the emphasis should be not on measuring the performance of individual functional areas but on measuring the performance of the entire process. The choice of the most appropriate process based measure is generally based on factors such as inclusiveness, universality, measurability, consistency, and non-redundancy of the process measures (Beamon, 1999; Melnyk, et al., 2004). A process based performance measurement system emphasizes developing appropriate structures for accountability and responsibility within the firm (Eccles and Pyburn 1992).

In general a higher level of agreement between the operative goals of departments or business units within a firm promotes coordinated cross-functional initiatives. Thus, goal congruence between sub-units promotes internal integration within the organization.

In summary, Figure 1 indicates the relationship between business process orientation (adoption of business processes and establishment of process based performance measurement system), goal congruence and internal integration.

Figure 1: Relationship between business process orientation, goal congruence, and internal

integration

The above discussion leads us to offer the following three propositions:

Proposition 1: Firms that adopt a business process orientation achieve a higher level of

goal congruence than firms that do not.

Proposition 2: Firms that adopt a process based performance measurement system (at

the firm level) achieve a higher level of goal congruence than firms that do not.

Proposition 3: Firms that achieve a higher level of goal congruence achieve a higher

level of internal integration than firms that do not.

3.2 Process based supply chain performance measurement system and external integration

As noted earlier, firms move from internal integration to external integration. External integration occurs initially by joint initiatives by a firm and its immediate suppliers / customers and then extends to the entire supply chain. From the perspective of organizational theory, supply chains exhibit sequential interdependency (Thompson, 1967). The potential for conflict increases with interdependency. However, conflict can be reduced by appropriately structuring the relationship between partners – formal definition of the roles and responsibilities of each partner, metrics to track performance, measurement procedures, and regulation of the system. Structure promotes integration by reducing equivocality (i.e. the level of ambiguity in relationships between supply chain partners). Using this theoretical lens, we argue that structure is provided by the performance measurement system (SCPM). In short, adoption of SCPM promotes higher degree of external integration.

While developing a system for SCPM, partners should consider the collective system-wide (supply chain) goals rather than individualized local goals (Lee, 2004). Systems theory supports this rationale. In reality, however, developing collective system-wide goals is

Degree of adoption of the following business processes:

1. Order fulfillment 2. Procurement

3. Demand management

4. New product development

5. Customer relationship management

6. Cash to cash cycle 7. Physical distribution and

planning process

Degree of adoption of process based measurement system:

1. Definition of process measures.

2. Setting standards

3. Assigning responsibilities for achieving standards

4. Fixing accountabilities 5. Regulation of the system

Goal congruence (Internal) Internal Integration P1 P2 P3

impeded by the fact that each partner has its own organizational goals and performance measurement system. Identifying congruent goals is likely to be facilitated by when partners tailor the SCPM system to match the type of supply chain (Fisher, 1997; Lee, 2002).

In summary, Figure 2 indicates the relationship between adoption of process based supply chain level performance measurement system and external integration.

The above discussion leads us to the following proposition:

Proposition 4: Supply chains that adopt process based performance measurement

systems achieve a higher degree of external integration than supply chains that do not.

Figure 2: Relationship between adoption of process based supply chain performance

measurement system and external integration

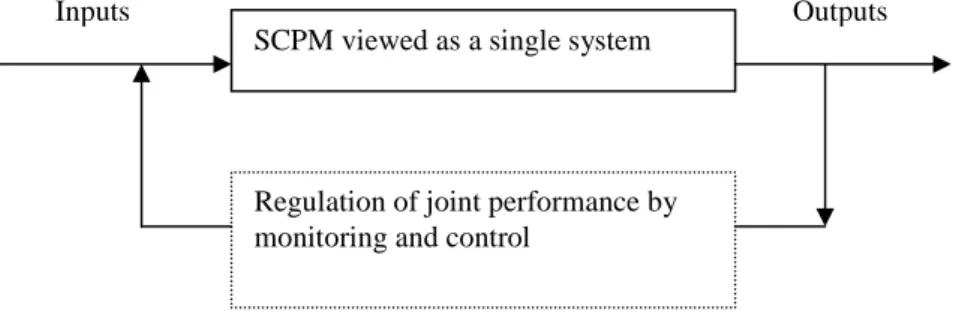

3.3 Monitoring and controlling SCPM leads to sustaining SCI

Sustaining any business initiative requires that participants agree to long term commitments (Ghemawat, 1991). The large body of strategic sourcing literature (Monzcka and Trent 1995; Narasimhan and Jayaram 1998) also supports the viewpoint that sustaining SCI requires long-term commitment of participants.

Both systems theory and goal theory literature suggest that long-term business commitment requires constant monitoring and control of SCPM. This is best achieved by means of a closed-loop system – one that provides regular, timely feedback on performance to all participants that is used to regulate the system. The closed loop systems approach is shown in Figure 3. Monitoring and control helps in improving supply chain performance where the partners continue to derive strategic benefits. As partners realize the benefits of integration, their commitment to tighter relationships with other partners increases thus leading to a higher level of supply chain integration.

Figure 3: Closed loop systems approach for regulating performance measurement system

Monitoring and control is a dynamic process that involves providing regular and timely feedback to all partners. This means that the contribution of each partner is tracked and compared to standards. Deviations are noted and corrective actions are undertaken. Any problems arising due to misalignment of performance measurement systems among the

SCPM viewed as a single system

Regulation of joint performance by monitoring and control

Inputs Outputs

Adoption of process based supply chain level performance measurement

supply chain partners are identified and resolved (Korpela, et al., 2001). This leads us to the following proposition on monitoring and control of SCPM.

Proposition 5: Supply chains that monitor and control joint performance of supply

chain partners achieve greater degree of sustained supply chain integration than those that do not.

4

Implication for managers and concluding comments

In this brief paper, we present a set of five propositions that provide a basis for a theory on how suitably structured SCPM can facilitate sustaining SCI. These propositions are testable and are based on sound multiple theoretical perspectives and prior research. We have used theoretical lens from multiple theories to explain the linkage between SCPM and SCI. These propositions can be used to develop hypotheses that may be tested using real world data. This will help in theory building and theory testing in the field of supply chain management.

While a few existing research studies prescribe what supply chain measures can be adopted by firms / supply chains, not much attention has been paid to process based supply chain measures that are applicable to different types of supply chains (such as functional, innovative, risk hedging or agile supply chains). We hope to have set the stage for further research on process based measures that are unique or common to different supply chain types.

We can draw several normative implications from this study. First, this study provides a perspective that accomplishing supply chain integration (SCI), which helps firms and supply chains derive strategic benefits, is not a one-time attainment. Sustaining supply chain integration is just as important. One of the major roadblocks to sustaining SCI is the lack of a proper supply chain performance measurement system. Development of supply chain wide performance measurement (SCPM) facilitates sustaining SCI. Second, sustaining supply chain integration requires not only the development of appropriate measures but also a system to measure, monitor, and regulate joint performance of several supply chain participants. Third, we show that while developing performance measurement system at the firm level, managers should recognize that firms should adopt a cross functional business process orientation and develop a process based measurement system at the firm level to facilitate internal integration. Fourth, while developing performance measurement system at the supply chain level, managers should recognize that supply chain participants should adopt a process based measurement system to facilitate external integration. Fifth, supply chain managers should note that monitoring and controlling the joint performance of supply chain participants helps in sustaining external integration. In summary, this paper provides the outlines of a generalized framework for establishing performance measurement systems for sustaining supply chain integration.

4

References

Aryee, G., C. Lalwani and M.M. Naim (2005). Supply Chain Integration Using a Maturity Scale: Review of Existing Frameworks. In the proceedings of: Sixteenth Annual Conference

of POMS, Chicago, IL, April 29 – May 2, 003-0056, 1-20.

Beamon, B. M. (1998). Supply Chain Design and Analysis: Models and Methods.

Beamon, B. M. (1999). Measuring Supply Chain Performance. International Journal of

Operations & Production Management, 19, 3, 275-292.

Brewer, P.C. and T.W. Speh, (2000). Using the Balanced Score Card to Measure Supply Chain Performance. Journal of Business Logistics, 21, 1, 75 – 93.

Bullinger, H., M. Kuhner and A. Van Hoof (2002). Analyzing Supply Chain Performance Using A Balanced Measurement Method. International Journal of Production Research, 40,

15, 3533-3543.

Checkland, P. (1993). Systems Thinking, Systems Practice. John Wiley and Sons, Chichester, U.K.

Davenport, T. H. (1993). Process Innovation: Reengineering work through Information

Technology, Harvard Business School Press, Boston, MA

Droge, C., J. Jayaram and S. K. Vickery (2004). The effects of internal versus external integration practices on time-based performance and overall firm performance. Journal of

Operations Management, 22, 6, 557-573.

Eccles, R.G. and P.J. Pyburn (1992). Creating a Comprehensive System to Measure Performance. Management Accounting, 74, 4, 41- 44.

Emerson, R.E. (1962). Power – Dependence Relations. American Sociological Review, 27, 1, 31-41.

Fisher, M. L. (1997). What Is the Right Supply Chain for Your Product? Harvard Business

Review, 75, 2, 105-117.

Frohlich, M. T. and R.Westbrook (2001). Arcs of Integration: An International Study of Supply Chain Strategies. Journal of Operations Management, 19, 2, 185–200.

Ghemawat, P. (1991). Commitment: The Dynamic of Strategy, The Free Press, New York, NY.

Gunasekaran, A., C. Patel, E. Tirtiroglu (2001). Performance Measures and Metrics in a Supply Chain Environment. International Journal of Operations & Production Management,

21, 1, 71-87.

Gunasekaran, A., C. Patel, and R.E. McGaughey (2004). A Framework for Supply Chain Performance Measurement. International Journal of Production Economics, 87, 3, 333-347. Holmberg, S. (2000). A Systems Perspective on Supply Chain Measurements. Internal

Journal of Physical Distribution and Logistics Management, 30, 10, 847-868.

Johnson, R.A., F.E. Kast and J.E. Rosenzweig (1963). The Theory and Management of

Systems. McGraw Hill Book Company, New York, NY.

Korpela, J., A. Lehmusvaara and M. Tuominen (2001). An Analytic Approach to Supply Chain Development. International Journal of Production Economics, 71, 1-3, 145-155. Lambert, D. M. and Pohlen, T. L. (2001). Supply Chain Metrics. The International Journal of

Logistics Management, 12, 1, 1-19.

Lapide, L. (2000). True Measures of Supply Chain Performance. Supply Chain Management

Review, 4, 3, 25-27.

Lawrence, P.R. and J.W. Lorsch (1967). Differentiation and Integration in Complex Organizations. Administrative Science Quarterly, 12, 1, 1-47.

Lee, H. L. (2002). Aligning Supply Chain Strategies with Product Uncertainties. California

Management Review, 44, 3, 105-119.

Lee, H. L. (2004). The Triple-A Supply Chain. Harvard Business Review, 82, 10, 102 – 112. Linderman, K., R.G. Schroeder, S. Zaheer and A.S. Choo (2003). Six Sigma: A

Goal-Theoretic Perspective. Journal of Operations Management, 21, 2, 193-203.

McCormack, K. and B. Johnson (2001). Business Process Orientation, Supply Chain Management and the E-Corporation. IIE Solutions, 33, 10, 33-39.

Melnyk, S.A., D.M. Stewart and M. Swink (2004). Metrics and Performance Meaurement in Operations Management: Dealing with the Metrics Maze. Journal of Operations

Management, 22, 3, 209-217.

Moberg, C.R. and T.W. Speh (2003). Evaluating the relationship between questionable business practices and the strength of supply chain relationships, Journal of Business

Logistics, 24, 2, 1-20.

Monczka, R. M. and R.J. Trent (1995). Purchasing and Sourcing strategies: Trends and

Implications, Center for Advanced Purchasing Studies, Tempe, AZ.

Narasimhan, R. and J. Jayaram (1998). Causal Linkages in Supply Chain Management: An Exploratory Study of North American Manufacturing Firms. Decision Sciences, 29, 3, 579 – 599.

Pfeffer, J. and G.R. Salancik (1978). The external control of organizations: a resource

dependence perspective. : Harper and Row, New York, NY.

Pollen, T. (2005). Supply Chain Metrics: Linking Performance with Shareholder Value.

CSCMP Explores, Spring / Summer, 1-15.

Rosenzweig, E. D., A.V. Roth and J.W. Dean (2003). The Influence of An Integration Strategy On Competitive Capabilities and Business Performance: An Exploratory Study of Consumer Products Manufacturers. Journal of Operations Management, 21, 4, 437-456. Stevens, G. C. (1990). Successful Supply-Chain Management. Management Decision Annual,

28, 8, 25-26.

Thompson, J. (1967). Organizations in Action. McGraw Hill, New York, NY.

5

Biography

Dr. Abirami Radhakrishnan is an Assistant Professor of Management at Morgan State University. She obtained her Ph.D. from Clemson University. Her research interests include performance measurement systems, supply chain integration, current trends in supply chain management and role of inter-organizational information systems in supply chains.

Dr. V “Sri” Sridharan is presently a Visiting Professor at EM-Lyon, Ecully, France. He is a Professor of Operations and Supply Chain Management at Clemson University. His current research interests concern supply chain management and revenue management. His papers have appeared in a number of journals including European Journal of Operational

Research, Journal of Operations Management, Management Science, and Operations Research.

Douglas N. Hales is an Assistant Professor of Supply Chain Management at the University of Rhode Island, USA. He has authored several peer-reviewed journal and conference articles on process improvement techniques. Prior to completing his Ph.D. at Clemson University, he spent twenty-two years in various management positions including the U.S. Marine Corps, Plastics, Construction, and Non-Profit industries.