Available Online at www.ijpret.com 228

INTERNATIONAL JOURNAL OF PURE AND

APPLIED RESEARCH IN ENGINEERING AND

TECHNOLOGY

A PATH FOR HORIZING YOUR INNOVATIVE WORK

DESIGN AND FABRICATION OF IMPROVED WHEELCHAIR FOR DISABLED

DEVENDRA JANGID, PROF. SATISH G. SONWANE,SHUBHAM BHUJADE, NITIN SINGHDepartment of Mechanical Engineering., Dr. Babasaheb Aambedkar College of Engineering & Research, Wanadongri, Hingna Road, Nagpur- 441110, Maharashtra. INDIA

Accepted Date: 15/03/2016; Published Date: 01/05/2016

\

Abstract: Now-a-Days everyone needs a medium to transport or move from one place to another. Healthy and fit people can manage to use their legs to move or even they can use a vehicle to cover long distances. But some unfortunate people like the disabled or the people suffering from paraplegia, partial paralysis, Polio and other such dreadful diseases which lock their daily essential motion in their life and make them dependent on others to even move a muscle. So as a provision for them to become Self-reliant in terms of efficient movement from one place to other or for their locomotive purpose, we have come up with this idea of improved wheelchair for the disabled. According to WHO there are about one billion people who are suffering from many disabilities, so it’s a very eyebrow raising figure and we engineers should use our knowledge to help this unfortunate people. So we have designed and are fabricating one such self-operated wheelchair powered by lever and chain sprocket drive mechanism. As all people can’t afford electrical wheelchairs as they are expensive, so we have come up with this project which is really economical and affordable even by the poor.

Keywords: Mechanical advantage; Effort; Lever; Roller chain.

Corresponding Author: MR. DEVENDRA JANGID

Access Online On:

www.ijpret.com

How to Cite This Article:

Available Online at www.ijpret.com 229 INTRODUCTION

This Paper describes the technical feasibility and social benefits of how can the wheel sprocket application can surpass the expensive electrical motor system and cut the high construction cost and provide an affordable improved wheelchair with same or more efficiency which a normal electrical wheelchair will give. The project completely aims on fulfilling the following objectives.

To develop a wheelchair which will require less effort to maintain same speed and will be able to operate on road and off-road rough terrains.

To develop a low maintenance and economic design of wheelchair affordable by all.

To develop a robust design of wheel, sprocket, lever mechanism to open a provision in future development of such mechanisms even for automobile applications to find a substitute for conventional energy sources and eco friendly applications.

METHODOLOGY

The various stages of development of a lever drive system are described. The use of both roller and friction clutches are discussed and the means for controlling forward, reverse, and braking are included. The current system allows good maneuverability without requiring hand skills and may be effective for quadriplegics.

Available Online at www.ijpret.com 230 motion and by finger pressure for reverse. Neutral or freewheeling occurred when no pressure was applied. The concept proved to be quite effective, but the only braking possible was by engaging reverse, which locked the drive wheels. This did not allow speed and directional control while descending slopes.. Handgrip levers proved ineffective. Rotation of the handgrip was more promising, but a second hinge point on the lever that utilized inward motion of the hands proved to be a satisfactory control means and promised to be useful for quadriplegics and others with limited use of the hands. Further experiments showed that selecting neutral (i.e., releasing the roller clutch) was not easily achieved; and the operator was never quite sure if the system was in forward, neutral, or reverse until the stroke was engaged. Meanwhile the clutch system was greatly improved; it required little force and motion to engage or disengage. Brubaker suggested disconnecting the roller clutch and using the friction clutch for all three functions: forward, reverse, and braking. The current prototype is based on this concept. When the levers are in the normal or rest position, the clutch is disengaged. Inboard movement of the levers engages the clutch, allowing propulsion in either direction or use as a brake. The clutch currently in use is a brake drum using external brake shoes with no asbestos brake lining. Propelling the wheelchair is similar to rowing or sculling a boat, with the lateral motion of the levers comparable to feathering the oars so that they do not drag on the return stroke. This requires some practice for effective use, but once achieved allows maneuverability that is comparable to hand rims.

FABRICATION AND CHARACTERISTICS

The design of the wheelchair body is simple and robust in, easily fabricated and no requirement of a high mechanized workshop to run the manufacturing process.

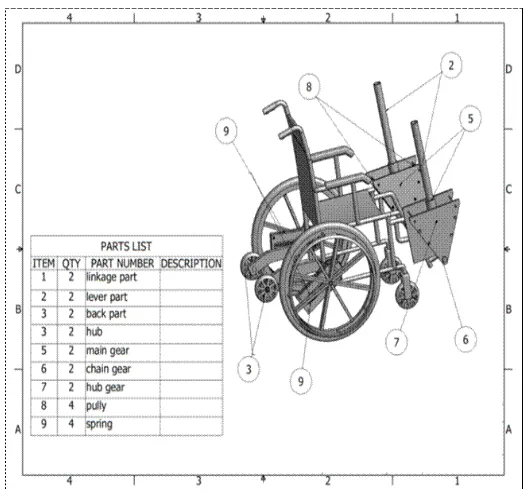

The different parts of the wheelchair assembly are given below:

Lever

Sprocket

Foot rest

Caster wheel

Tires with rim

Chain

Available Online at www.ijpret.com 231 Body

Hand brake

Main gear

Hub gear

Hub

Fig. 1 PRO-E design of Improved wheelchair

DESIGN ANALYSIS AND CALCULATION

The design is totally practical and precisely modified for efficient working and the respective phenomena including the model testing and final application for finishing is completely verified. The design is totally emphasized on low maintenance objective and high performance and high tool life.

The stress analysis and testing on computer-aided software and it slides are presented below.

Design parameters

Available Online at www.ijpret.com 232 Design power = Rated power * load factor

Tooth load =design power / Pitch line velocity

Length of chain in pitches = Lp=(T1+T2)/2+2C/p + p(T1-T2)²/40C.

Well the design analysis showed above are totally definite and practically applicable.

Fig. 2 Creo simulate results

Fig. 3 Creo simulate results

Available Online at www.ijpret.com 233 ADVANTAGES AND APPLICATION

Provide mechanical advantage through lever.

Provide new product line in the market.

Cost effective

Less effort.

Low Maintenance cost.

Able to operate on rough terrains.

There are no electrical components associated with this device

REFERENCES

1. BENNEDIK R, ENGEL P, HILDEBRANDT G: Der Rollstuhl-Schindele-Verlag Rheinstetien, 1978. 2. BRUBAKER CE, MCCLAY IS, MCLAURIN CA: Effect of seat position on wheelchair propulsion efficiency. Prue 2nd Int Conj. Rehab Eng, Ottawa, Canada, June 1984.

3. BRUNING T, MCLAURIN CA, HENDERSON J: Wheelchair Mobility. University of Virginia Rehabilitation Engineering Center, 1976-1981, p . 107.

4. SEELIGER KLAUS: Birkenkopfstrasse 10 3500, Kassel, W. Germany, November 1984.

5. Glaser RM, Sawka MN, Young RE, Suryaprasad AG. Applied physiology for wheelchair design. J Appl Physiol 1980: 48(1): 41-4.