Scaling of Convective Heat Transfer Enhancement Due to Flow Pulsation in an Axisymmetric Impinging Jet

Full text

Figure

Related documents

Effect of nozzle spacing on heat transfer and fluid flow characteristics of an impinging circular jet in cooling of electronic components.. Performance of turbulence

Abstract — Experimental measurements for the circumferential variation of Nusselt number and effectiveness for a straight and an inclined slot jet impinging on a

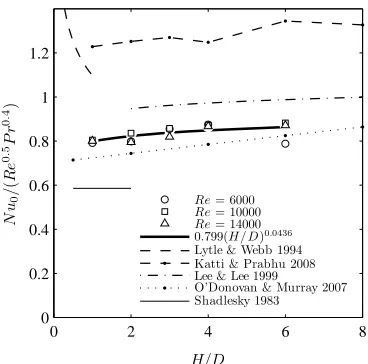

Since vortices also affect the magnitude and direction of velocity fluctuations close to the impingement surface, the vorti- cal nature of an impinging jet has a significant

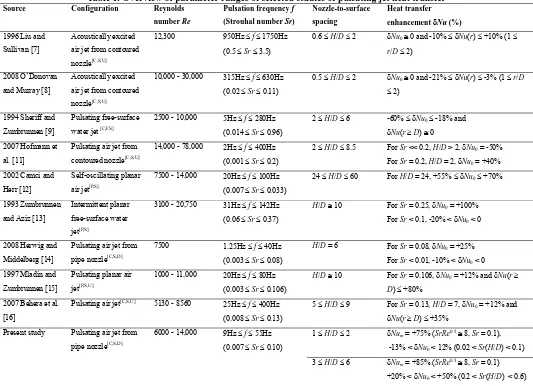

Peaks in heat transfer outwith the stagnation region of the jet were investigated and a connection between the driving frequency of the jet and changes in the rate of heat transfer

Experimental Paper on Flow and Heat Transfer Characteristics of Single Jet Impinging on Dimpled Surface by Yonghui et al., [13] stated that The local Nusselt number in

By decreasing jet-to-plate spacing and jet inlet width and increasing inlet Peclet number, the ow reversal in the vicinity of heated wall disappeared, and the local Nusselt

The factors which influence the heat transfer by jet impingement includes nozzle geometry, jet to plate distance, jet incidence angle, radial distance from stagnation

Heat transfer rates in case of impinging jets are affected by various parameters like Reynolds number, nozzle plate spacing, radial distance from stagnation point, Prandtl