Available online at

http://www.iaeme.com/IJMET/issues.asp?JType=IJMET&VType=6&IType=11 ISSN Print: 0976-6340 and ISSN Online: 0976-6359

© IAEME Publication

PERFORMANCE AND EMISSION

CHARACTERISTICS OF MAHUA

BIODIESEL IN A DI- DIESEL ENGINE

Chaitanya P

Junior Lecturer, Government Vocational Junior College, Visakhapatnam, Andhra Pradesh, India

P. V. Rao

Associate Professor, Dept. of Mechanical Engineering, Andhra University, Visakhapatnam, Andhra Pradesh, India

A. Swarna Kumari

Professor, Dept. of Mechanical Engineering, Jawaharlal Nehru Technological University Kakinada,

Andhra Pradesh, India.

ABSTRACT

This work is focused to determine the performance and emissions characteristics of a naturally aspirated direct ignition diesel engine fueled with diesel fuel (DF), mahua biodiesel (MBD) and preheated mahua biodiesel (MBD-PH). The fatty acid composition of MBD is determined and its properties like density, viscosity, cetane number, calorific value and iodine value are also determined. Engine performance tests showed that brake specific fuel consumption of MBD is higher than that of DF. The emission results from experimentations supported that MBD has substantially decreased the carbon monoxide, hydrocarbons, nitrogen oxides and smoke emissions. It is observed that MBD-PH has further reduced the emissions. Thus, mahua biodiesel can be used as an alternative fuel in automotive diesel engines.

Key words: Emissions, Performance, Mahua Biodiesel, Fatty Acid Composition, Properties.

Cite this Article: Chaitanya P, P. V. Rao and A. Swarna Kumari. Performance and Emission Characteristics of Mahua Biodiesel In A DI- Diesel Engine, International Journal of Mechanical Engineering and Technology, 6(11), 2015, pp. 123-131.

1. INTRODUCTION

Burning of fossil fuels poses a strong threat to our environment as it emits harmful gases like carbon dioxide (CO2), carbon monoxide (CO), Sulfur oxides (SOx), and

Nitrogen oxides (NOx) [1]. Several studies [2] have shown that diesel and biodiesel blends reduce smoke opacity, particulates, un-burnt hydrocarbons, carbon dioxide and carbon monoxide emissions, but nitrous monoxide emissions have slightly increased. The brake power of biodiesel was nearly the same as with petrodiesel, while the specific fuel consumption was higher than that of petrodiesel [3].

Biodiesel is referred as mono-alkyl esters of long-chain-fatty acids made from renewable lipid sources (vegetable oils, or animal fats) by a trans- esterification chemical reaction. Advantages of biodiesel include domestic origin, renewability, biodegradability, higher flash point, inherent lubricity, reduction of most regulated exhaust emissions, as well as miscibility with petrodiesel. Several scientists [4-12] have investigated the effects of biodiesel fuel on exhaust emissions, and found a significant reduction in carbon monoxide, sulfur, smoke, particulate matter and noise emissions.

2. MAHUA OIL

The inedible oil extracted from seeds of mahua as shown in figure 1, is the resource for the production of biodiesel which is abundantly available in India. It has a carbon chain between C14 and C24. It has a very high viscosity, and density. Different

methods are being used to reduce the viscosity of oils such as pyrolysis, cracking and transesterification.

Figure 1 Mahua oil Seeds

2.1. Transesterification

In a transesterification reaction, one mole of triglyceride reacts with three moles of alcohol (molar ratio of methanol to vegetable oil of 3:1) to form one mole of glycerol and three moles of the respective fatty acid alkyl esters. The process is a sequence of three reversible reactions, in which the triglyceride molecule is converted step by step into diglyceride, monoglyceride and glycerol. The process of transesterification removes glycerin from the triglycerides and replaces it with the alcohol used for the conversion process. This process decreases the viscosity but maintains the cetane number and the heating value. MBD has a higher cetane number than diesel fuel, no aromatics, no sulfur, and contains 10–11 % oxygen by weight [13].

3. FUEL PROPERTIES

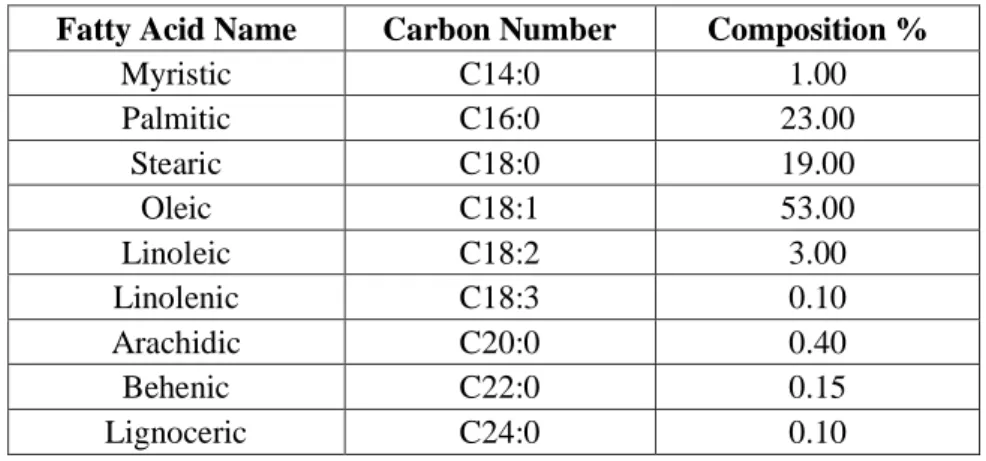

3.1. Fatty Acid Composition of Mahua Biodiesel

varying one or both of them can lead to a change in fuel properties. For biodiesel, this issue is rendered more complicated because its fatty ester composition reflects the fatty acid profile of the feedstock used for its production. The fatty acid composition of MBD is as shown in Table 1. It has a carbon chain between C14 to C24.

Table 1 Fatty acid Composition of Mahua Biodiesel Fatty Acid Name Carbon Number Composition %

Myristic C14:0 1.00 Palmitic C16:0 23.00 Stearic C18:0 19.00 Oleic C18:1 53.00 Linoleic C18:2 3.00 Linolenic C18:3 0.10 Arachidic C20:0 0.40 Behenic C22:0 0.15 Lignoceric C24:0 0.10

3.2. Physical and Chemical Properties of Mahua Biodiesel

The physicochemical properties of MBD and DF are tabulated in Table 2. 1. Viscosity

The viscosity is a measure of the internal friction or resistance of a substance to flow. As the temperature of the substance is increased, its viscosity decreases and it is therefore able to flow more readily. It increases with the increase of molecular weight and decrease as the number of double bonds increases. It affects the atomization quality, size of drop and penetration. Fuel with high viscosity tend to form larger droplets on injection which can cause poor fuel atomization during the spray, increases the engine deposits, needs more energy to pump the fuel, and wears fuel pump elements and injectors.

2. Density

Density affects the mass of fuel injected into the combustion chamber and the air–fuel ratio. This is because fuel injection pumps meter fuel by volume not by mass and a denser fuel contains a greater mass in the same volume. The biodiesel fuel has more density than diesel and hence it is less compressible. If a fuel is less compressible, the pressure will build more quickly and the fuel will be injected into the combustion chamber earlier in the compression cycle. Therefore it reaches the injector nozzle within a very short time.

3. Cetane number

The cetane number is a relative measure of the delay time between injection and auto-ignition of fuels. Fuels with a lower cetane number can be accumulated before the start of combustion, result in poor combustion characteristics and lead to excessive emissions of smoke and particulates. This leads to a sudden pressure rise followed by pressure pulses and subsequent vibrations causing diesel knock, which leads to poor thermal efficiency, excessive noise and reduced life of engine components. Higher cetane numbers improve cold starting of the engine, increase fuel economy, reduce

exhaust emissions, decrease knocking and noise, and improve the overall durability of the engine.

4. Iodine Value

Iodine value is a measure of total unsaturation within a mixture of fatty acid. It is expressed in grams of iodine which react with 100 g of the respective sample when formally adding iodine to the double bonds. The iodine value of a vegetable oil or animal fat is almost identical to that of the corresponding methyl esters.

5. Flash point

The flash point is a measure of the temperature to which a fuel must be heated such that the mixture of vapor and air above the fuel can be ignited. It is the temperature at which it will ignite when exposed to a flame or a spark. The flash point of biodiesel is higher than that of diesel fossil fuel, which is safe for handling and storage purpose. 6. Calorific value

The heat of combustion is important for estimating fuel consumption: the greater the heat of combustion, the lower the fuel consumption. The higher the calorific value, the greater is its utility as a potential fuel. The biodiesel samples have lower calorific values than that of diesel fuel but have the calorific values within the ASTM standard limits.

Table 2 Properties of Diesel [14] and Mahua biodiesel fuels

Property Units Diesel Mahua biodiesel ASTM D6751-02

Carbon Chain Cn C8-C32 C14- C24 C12-C22

Molecular Formula CHO C18H36 C18.5H36O2 ---

Molecular Weight g/mol 226 281 292

Kinematic Viscosity cSt @40 oC 2.25 4.1 1.9-6.0

Density g/cm3 0.825 884 870-900

Cetane Number --- 49 64 47 min.

Iodine Value g I2/100 g 38 70 120 max.

Flash Point Temp. oC 70 140 130 min.

Calorific Value MJ/kg 42.5 36.95 ---

4. EXPERIMENTATION

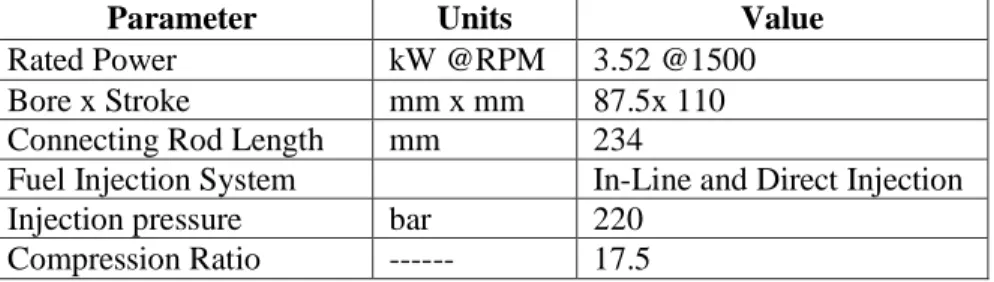

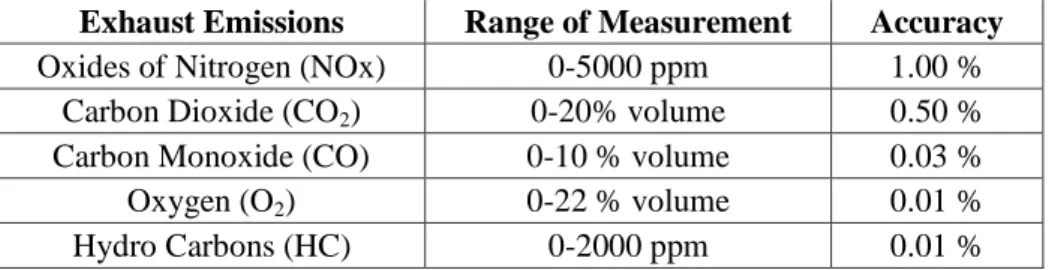

The experimentation is carried on a naturally aspirated single cylinder, four stroke diesel engine, whose technical specifications are as shown in Table 3 and the test rig setup is as shown in figure 2. The exhaust gas analyzer specifications are shown in table 4.

Table 3 Technical Specifications of Diesel engine test rig: Kirloskar- TV1

Parameter Units Value

Rated Power kW @RPM 3.52 @1500

Bore x Stroke mm x mm 87.5x 110 Connecting Rod Length mm 234

Fuel Injection System In-Line and Direct Injection

Injection pressure bar 220

Figure 2 Experimental setup: Diesel engine with Exhaust Gas Analyzer Table 4 Technical Specifications of Exhaust Gas Analyzer

Exhaust Emissions Range of Measurement Accuracy Oxides of Nitrogen (NOx) 0-5000 ppm 1.00 %

Carbon Dioxide (CO2) 0-20% volume 0.50 %

Carbon Monoxide (CO) 0-10 % volume 0.03 %

Oxygen (O2) 0-22 % volume 0.01 %

Hydro Carbons (HC) 0-2000 ppm 0.01 %

5. RESULTS AND DISCUSSIONS

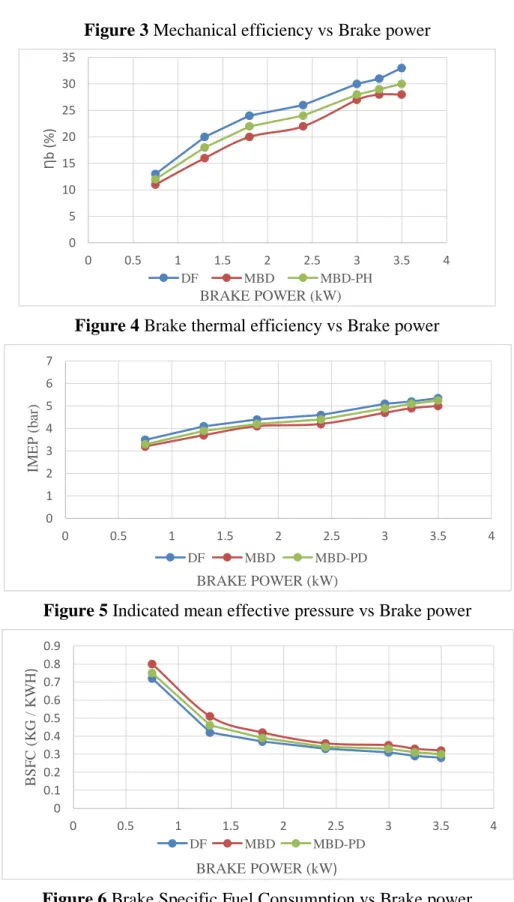

5.1. Performance characteristics

From figure 3, it is observed that with increasing brake power, the mechanical efficiency (ηm) of DF, and MBD has increased at all loads. The ηm of MBD is higher

than that of diesel DF. And a further increase in the ηm is observed when MBD is

preheated. From figure 4, it can be seen that the Brake thermal efficiency (ηb ) of

MBD is lower than that of diesel fuel. The main factor that contributes to this decrease is higher viscosity of MBD. It is also seen that ηb MBD-PH is in between

that of MBD and DF because preheating of the biodiesel has reduced the viscosity which inturn increased efficiency. From the figure 5, it can be seen that the indicated mean effective pressure (IMEP) has decreased with the usage of MBD. The brake specific fuel consumption (BSFC) of MBD is observed to be higher than that of DF as shown in figure 6. This is because of the higher viscosity and lower calorific values of the MBD. 0 10 20 30 40 50 60 70 80 0 0.5 1 1.5 2 2.5 3 3.5 4 Ƞ m (%) BRAKE POWER (kW) DF MBD MBD-PH

Figure 3 Mechanical efficiency vs Brake power

Figure 4 Brake thermal efficiency vs Brake power

Figure 5 Indicated mean effective pressure vs Brake power

Figure 6 Brake Specific Fuel Consumption vs Brake power

5.2. Emission Characteristics

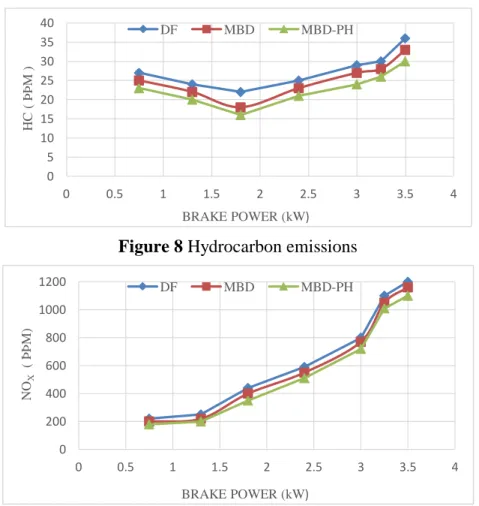

Figure 7 shows the variation of CO with brake power for DF and MBD. It is observed that CO emissions from MBD are lower. The presence of oxygen in MBD promotes the combustion process and leads to decrease in CO and HC emissions. At full load the reduction in the HC is believed to be due to the presence of oxygen in the fuel which promotes the combustion process [15]. The decreasing trend of unburnt HC as

0 5 10 15 20 25 30 35 0 0.5 1 1.5 2 2.5 3 3.5 4 Ƞ b (%) BRAKE POWER (kW) DF MBD MBD-PH 0 1 2 3 4 5 6 7 0 0.5 1 1.5 2 2.5 3 3.5 4 IM E P ( b ar ) BRAKE POWER (kW) DF MBD MBD-PD 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0 0.5 1 1.5 2 2.5 3 3.5 4 B S F C ( K G / K W H ) BRAKE POWER (kW) DF MBD MBD-PD

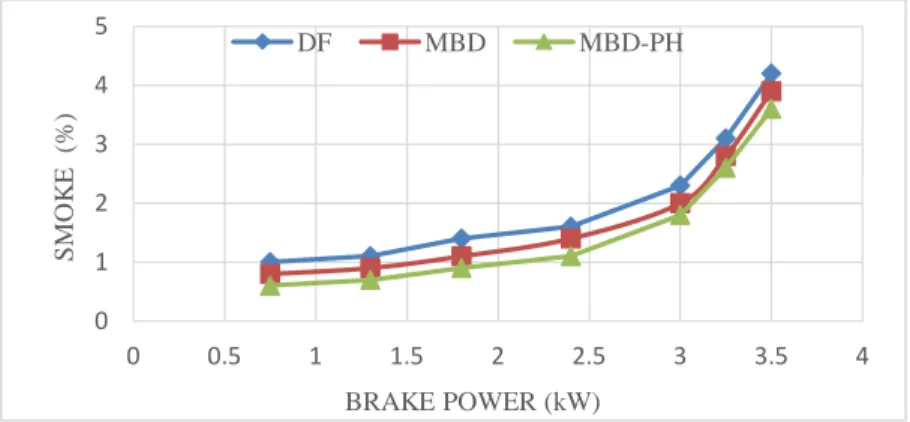

shown in Figure 8 can also be due to the reduction in ignition delay. From figure 9 it is observed that NOx emissions have reduced while using MBD. The NOx emissions

are affected by the time the fuel takes to vaporize and mix with the compressed hot air. Fuels with higher cetane numbers reduce the ignition delay and there by result less mixture to being involved in premixed combustion. Hence a lower NOx emissions

are observed in MBD due to its high cetane number. Further oxidation is improved because of the presence of oxygen in the MBD which reduced NOx. From the figure

10, it is observed that there is a decrease in the smoke emitted from MBD. A decrease in smoke levels is observed at all brake power conditions.

Figure 7 Carbon monoxide emissions

Figure 8 Hydrocarbon emissions

Figure 9 Nitrogen oxides emissions

0 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0 0.5 1 1.5 2 2.5 3 3.5 4 CO (% ) BRAKE POWER (kW) DF MBD MBD-PD 0 5 10 15 20 25 30 35 40 0 0.5 1 1.5 2 2.5 3 3.5 4 H C ( ÞÞM ) BRAKE POWER (kW) DF MBD MBD-PH 0 200 400 600 800 1000 1200 0 0.5 1 1.5 2 2.5 3 3.5 4 NO X ( ÞÞM) BRAKE POWER (kW) DF MBD MBD-PH

Figure 10 Smoke emission

6. CONCLUSIONS

The experimentation was carried out with mahua biodiesel with and without preheating. A considerable decrease in the emission levels of carbon monoxide, hydrocarbons, nitrogen oxides and smoke were observed. A similar and a slightly lower efficiency were noted for mahua biodiesel when compared with that of diesel fuels. But a higher specific fuel consumption is observed for mahua biodiesel which can be taken care by pre heating the biodiesel. Thus mahua can be a considered as a sustainable renewable fuel which helps reduce emissions with a similar performance as that of a diesel engine.

REFERENCES

[1] Verma NM, Mehrotra S, Shukla A, Mishra BN (2010) Prospective of biodiesel production utilizing microalgae as the cell factories: a comprehensive discussion. Afr J Biotechnol 9(10):1402–1411

[2] Agarwal AK, Das LM. Biodiesel development and characterization for use as a fuel in compression ignition engines. Am Soc Mech Engrs J Eng, Gas Turb Power 2000; 123:440–7.

[3] Ayhan Demirbas. Progress and recent trends in biodiesel fuels: Energy conversion and management, Elsevier: 50 (2009) 14-34.

[4] Jayed M, Masjuki H, Saidur R, Kalam M, Jahirul M. Environmental aspects and challenges of oil seed produced biodiesel in South East Asia. Renewable and Sustainable Energy Reviews 2009; 13: 2452 – 62.

[5] Murugesan A, Umarani C, Chinnuswamy T R, Krishnan M, Subramanian R, Neduzchezhain N. Production and analysis of bio-diesel from non – edible oils – a review. Renewable and Sustainable Energy Reviews 2009; 13: 825 – 34. [6] Patil P D, Deng S. optimization of biodiesel production from edible and non –

edible vegetable oils. Fuel 2009; 88: 1302 – 6.

[7] Basha S A, Gopal K R, Jebaraj S. A review on biodiesel production, combustion, emissions and performance. Renewable and Sustainable Energy Reviews 2009; 13: 1628-34.

[8] Sun J, Caton J A, Jacobs T J. Oxides of nitrogen emissions from biodiesel – fueled diesel engines. Progress in Energy and Combustion Science 2010; 36:677 – 95.

[9] Szulczyk KR, Mc Carl BA. Market Penetration of biodiesel. Renewable and Sustainable Energy Reviews 2010; 14: 2426 – 33.

0 1 2 3 4 5 0 0.5 1 1.5 2 2.5 3 3.5 4 SMO K E (% ) BRAKE POWER (kW) DF MBD MBD-PH

[10] Qi D, Chen H, Geng L, Bian Y. Experimental studies on the combustion characteristics and performance of a direct injection engine fueled with biodiesel/ diesel blends. Energy Conversion and Management 2010; 51: 2985 – 92.

[11] Chauhan B S, Kumar N, Cho H M. A study on the performance and emission of a diesel engine fueled with Jatropha biodiesel oil and its blends. Energy 2011. [12] Xue J, Grift T E, Hansen A C. Effect of biodiesel on engine performances and

emissions. Renewable and Sustainable Energy Reviews 2011; 15: 1098 – 116. [13] P V Rao. Effect of properties of karanja methyl ester on combustion and NOx

emissions of a diesel engine. Journal of Petroleum Technology and Alternative Fuels, vol: 2, 2360-8560, pp: 63-75.

[14] P V Rao and Basava V A Rao. Influence of Physical and Chemical Properties of two biodiesel fuels on performance, combustion and exhaust characteristics in a DI- CI engine. Proceedings of ASME 2008 Internal Combustion Engine Division Spring Technical Conference. pp: 115-128.

[15] Nwafor OMI, Rice G, Ogbonna AI. Effect of advanced injection timing on the performance of rapeseed oil in diesel engines. Journal of Renewable Energy 2008; 21:433-44.

[16] R. Senthil Kumar and M. Prabu. Experimental Investigation of A Di Diesel Engine Using Tyre Pyrolysis Oil-Diesel Blends As A Biodiesel, International

Journal of Mechanical Engineering and Technology, 5(2), 2014, pp. 74 - 90.

[17] Shankar Suthar, Mangesh Kumar Chauhan and Dr. Mohammad Israr. Investigation and Analysis of Diesel Engine Using Bio Diesel, International

Journal of Mechanical Engineering and Technology, 6(2), 2015, pp. 56 - 61.

[18] Dr. Rajeshkumar U. Sambhe and Dr. Pankaj N. Shrirao. Performance Analysis of Single Cylinder (Di) Diesel Engine by Air Swirl Induction with Internally Threaded Inlet Manifold, International Journal of Mechanical Engineering and

Technology, 5(7), 2014, pp. 144 - 150.