2016 3rd International Conference on Information and Communication Technology for Education (ICTE 2016) ISBN: 978-1-60595-372-4

1 GENERAL INSTRUCTIONS

Recent studies suggest that natural gas is an efficient, clean energy, its huge storage capacity, the price is relatively low, the engine can be fueled with produce good economic and social benefits.

At present, natural gas, mainly in compressed gas cylinders are stored (CNG) used in gasoline vehicles. Its main application is by using a separate natural gas fuel supply piping system directly in the engine fueled with gasoline, burning this way is simple and practical, but unable to play natural gas as gaseous fuel in the engine fueled with natural Advantage. Therefore, the study and exploration of natural gas has important practical engineering in application mode on the engine.

Our vast mountainous area, transport diesel energy dependence, the use of alternative energy on the part of the natural gas and diesel fueled with diesel engines, both diesel can save valuable resources, diversification of natural gas may also be implemented on the engine application. Therefore, this article studies the calorific value when use of natural gas instead of diesel fuel on the engine part, variation of diesel power and economy, provided that the reference to the natural gas burning mode diesel engine and burning techniques.

2 OVERVIEW OF NATURAL GAS PHYSICAL AND CHEMICAL CHARACTERISTICS

[image:1.612.328.546.615.752.2]Physical and chemical properties compared to traditional gasoline and diesel fossil fuels, natural gas is different. The main component of natural gas is methane, the main hydrocarbon composed of two elements, the formula is CH4, the standard state density 0.7174kg/m3, less than air, light blue flames emit when burned. Physical and chemical properties of natural gas and diesel fuel such as are shown in Table 1. Due to the low energy density of natural gas, diesel fuel used in compression and storage often used way of compressed natural gas CNG volume before compression is about 1/600.

Table 1. Physical and chemical properties of natural gas.

Physical and chemical properties Natural

Gas Diesel

Stoichiometric Air-fuel

Ratio/kg/kg 17.25 14.3

Stoichiometric Air-fuel Ratio

V/V 9.52 9.42

RON 130 20~30

Cetane Number <10 45~65

Mixture Heat Value /(MJ/m3) 3.39 3.79

Low Heating Value/(MJ/kg) 50.0 42.5

Flame Propagation/(m/s) 34~37 -

Testing Research on Performances of Diesel Engine Fueled with

Natural Gas and Diesel Fuel Blends

Zongquan An

Wuhu Vocational and Technical College Wuhu, Anhui 241000, China

Zhaoming Huang

Hehai University Wentian College, Maanshan, Anhui 238000, China

Li Wang

Xuancheng Vocational and Technical College, Xuancheng, Anhui 242000, China

Ignition Limit/% 5~15 1.5~8.2

Ignition Temperature/℃ 537 230

As can be seen from Table 1 compares and gas research octane number higher ignition temperature higher than diesel compression ignition is not easy, so the use of blended diesel on the way, some diesel injection through the injector in the cylinder, in order to pressure from the intake manifold to ignite the fire burning supplied fuel gas and air are mixed, blended with natural gas to ensure viable.

3 TEST METHODS AND EQUIPMENT

Test fuel to 0# diesel and compressed natural gas (composed mainly of methane), on JL4JB1 diesel engine were carried out economic research and experimental than the amount of gas dynamic blending different alternatives. Substitute natural gas ratio is defined as the natural gas heat value and gross calorific value (diesel and natural gas calorific value and heat value) ratio, expressed as shown in Equation (1).

(1)

Wherein, RN/D ratio of natural gas alternative, HNatural Gas and HDieselFuel respectively calorific value calorific value of natural gas and diesel units of MJ.

[image:2.612.323.552.194.315.2]In order to achieve natural gas in diesel engines blended, the engine test bench adds a natural gas supply system, including high-pressure CNG cylinders, regulators, heat exchangers, gas meter and mixers, among mixer installation on the intake manifold to ensure that the supply of natural gas and air to form a homogeneous mixture. Natural gas supply system shown in Figure 1.

Figure 1. Fuel Supplying System of Diesel Engine.

Taking into account the natural gas supply in the form of a homogeneous mixture of diesel engine fueled with natural gas substitution ratio is too low (too lean mixture), which is due to the relatively high compression diesel engine in the compression process, the mixture is too lean gas and air will be squeeze into the face of a relatively large slot, resulting in incomplete combustion or fire, resulting in decreased economic diesel power. While natural gas air-fuel ratio is greater than diesel fuel, the high

natural gas instead of diesel engines will decline more than the excess air ratio, resulting in reducing diesel engine performance. Comprehensive analysis showed that natural gas instead of setting ratio of 0.2 to 0.8, and can ensure efficient natural gas co-firing test research.

Test equipment mainly CW160 type eddy current dynamometer, FC2210 type gas meter, FEV fuel gauge, MT20U2-developing ECU, SWK03 thermostatic cooling water systems and FEV TCM Rig system. Diesel main test parameters as shown in Table 2.

Table 2. Main parameters of diesel engine.

Type JL4JB1

Displacement/L 2.8

Bore×Stroke/mm×mm 93×102

Rated Power/Speed/(kW/ r·min-1) 65/3600

Maximum Torque/Speed/(N·m/

r· min-1) 221/1800

Mnimum BSFC/(g· (kW·h)-1) ≤224

Compressure Ratio/(-) 18.2

Combustion Chamber ω

4 TEST RESULTS AND ANALYSIS

4.1 Different alternatives to determine the ratio of the amount of natural gas supply

Diesel engine running on different operating conditions, the fuel injection quantity of each cycle vary, the amount of diesel fuel injection cycle using equation (2) calculation.

(2)

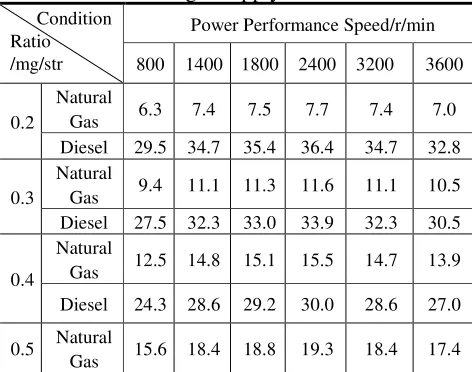

[image:2.612.69.283.505.592.2]Wherein, mDiesel diesel engine diesel injection amount per cycle, in units of mg/str; BDiesel is diesel fuel an hour, the unit is kg/h; n is the engine speed, the unit r/min; i is the number of cylinders.

Table 3. Different substitution ratio of natural gas supply.

Condition Ratio /mg/str

Power Performance Speed/r/min

800 1400 1800 2400 3200 3600

0.2

Natural

Gas 6.3 7.4 7.5 7.7 7.4 7.0

Diesel 29.5 34.7 35.4 36.4 34.7 32.8

0.3

Natural

Gas 9.4 11.1 11.3 11.6 11.1 10.5

Diesel 27.5 32.3 33.0 33.9 32.3 30.5

0.4

Natural

Gas 12.5 14.8 15.1 15.5 14.7 13.9

Diesel 24.3 28.6 29.2 30.0 28.6 27.0

0.5 Natural

Gas 15.6 18.4 18.8 19.3 18.4 17.4

/

N a t u r a l G a s N D

D i e s e l F u e l N a t u r a l G a s

H R

H H

=

+

Solenoid Valve Regulator

Mixture

Resonant

Air Filter Diesel Engine Intake

[image:2.612.317.553.568.754.2]Diesel 21.2 24.9 25.5 26.2 24.9 23.6

0.6

Natural

Gas 18.8 22.1 22.6 23.2 22.1 20.9

Diesel 18.1 21.3 21.7 22.3 21.2 20.1

0.7

Natural

Gas 21.9 25.8 26.3 27.1 25.8 24.4

Diesel 14.9 17.6 17.9 18.4 17.6 16.6

0.8

Natural

Gas 25.1 29.5 30.1 30.9 29.5 27.9

Diesel 11.8 13.9 14.2 14.6 13.9 13.1

In the diesel cycle fuel injection amount is calculated based on the combination of natural gas than the alternative definition, you can determine different substitution ratio per cycle diesel engine to determine the amount of natural gas supplied to the respective operating conditions needed using equation (3).

(3)

Where, mNaturalGas for the diesel-cycle gas injection quantity per unit of mg/str; hNaturalGas and

hDiesel respectively low calorific value gas and diesel

fuel, the unit is MJ/kg. Combining Equation (1), (2) (3) calculate the diesel engine is run in different conditions, different alternative than burning natural gas and - a hybrid diesel fuel supply amount per cycle, natural gas and diesel, as shown in Table 3.

4.2 Variation of different alternative diesel engine performance

Made diesel engine fueled with a different alternative than natural gas - in 800r / min, 1400r/min, 1800r/min, 2400r/min, 3200r/min and 3600r/min and dynamic study of a hybrid diesel fuel to run. During the experiment, always keep natural gas - diesel mixed with diesel fuel heating value of each of the original machine mode cycle fuel injection quantity of heat equal to the value. Test results are shown (dashed line in FIG original diesel engine torque level at the external characteristic of the rotational speed) in Figure.2.

(a) n=800r/min

(b) n=1400r/min

(c) n=1800r/min

(d) n=2400r/min

(e) n=3200r/min

(f)n=3600r/min

Figure 2. Fueled with a different alternative than gas - torque characteristics of diesel.

6 /

l 10

Diesel Diesel N D Natura Gas

NaturalGas

m h R

m

h

× ×

[image:3.612.58.297.33.165.2]As can be seen from Figure 2, the diesel engine fueled with natural gas - diesel blended fuels in certain alternative ratio, torque within the test speed range can exceed the original diesel engine levels of external characteristics (torque curve portion is located above the dashed line); at the same time with the speed increases, the torque characteristics than the original machine level when gas substitution ratio decreases; and low-speed alternative than small, high-speed alternative to large poorer than the burning efficiency; torque rises highest at 1800r / min, an increase of 6.8%.

Above diesel engine fueled with a different alternative than gas - diesel fuel blends performance analysis of different conditions torque variation of the view that (1) certain natural gas to replace diesel fuel with more than Replacement part, it is possible to improve the maximum combustion temperature of the cylinder to expand power stroke of the combustion cycle the temperature of the ladder, and the diesel combustion full extent improved, thereby improving the thermal efficiency, and therefore under the same heat value of the fuel supply condition, natural gas - diesel mixed fuel of torque will be higher than diesel original machine level; (2 ) when the engine low speed operation, the cylinder air movement is relatively weak, and lower power, lower average cylinder temperature, then replace the smaller lean mixture formed in the incomplete combustion is not easy to slit, whereas when the high-speed air movement is strong, resulting in high power average cylinder temperature, improve the natural gas mixture for complete combustion, the role of these factors make the rotation speed increases, natural gas - torque characteristics of diesel blended fuel exhibits exceed the original machine when the level of alternative ratios in reduced; (3) However, due to the diesel engine high speed, high load operation, the excess air ratio is relatively small, and is larger than the stoichiometric air-fuel ratio of natural gas and diesel, and therefore as the speed continues to rise, than the alternative increasing, and natural gas - diesel blended fuel excess air ratio will further decline, occur due to insufficient supply of oxygen content appear incomplete combustion phenomena, resulting in high speed, large alternative than burning efficiency is poor, torque down; ( 4) medium speed diesel engine is running, the cylinder air movement reasonable, pneumatic and thermal efficiency are high, in favor of diesel - natural gas mixed fuel combustion, and therefore the maximum torque rise.

4.3 Diesel engine fueled with natural gas - the best alternative to diesel ratio

Extraction of natural gas corresponding to the maximum torque from the experimental data of Fig. 2 - diesel hybrid alternative fuel ratio, and with the

external characteristics of the original diesel engine torque contrast, as shown in figure 3.

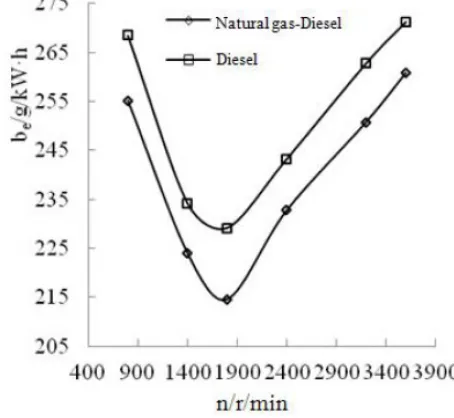

[image:4.612.318.557.106.304.2]Diesel blended fuel and diesel economy comparison Figure 4 shows the external characteristics of the diesel engine is running, the best alternative fuel than natural gas.

Figure 3. Best alternative than gas - torque characteristics of diesel.

Figure Natural Gas - The economic comparison of the external characteristics of diesel and diesel.

[image:4.612.318.545.337.546.2]5 CONCLUSION

Firstly, diesel to natural gas in the intake manifold mix blended way, can effectively improve the performance of diesel engine torque external characteristics. At different speeds, the best alternative fueled with natural gas is different than

Secondly, diesel engine is running at low speed for high replacement ratio at high speed for low replacement ratio.

Thirdly, at medium speed diesel engine fueled with natural gas sharpest increase in torque, compared to the original diesel engine maximum torque increased by 6.8%.

Fourthly, natural gas in diesel engines at a reasonable replacement for blending, can enhance engine power and economy, enhance the degree of enhancement of diesel engine.

6 ACKNOWLEDGMENT

Thanks to the supports and efforts From Natural Science Key Project of Anhui Educational Department (Project Number: KJ2016A753) for the essay work and publishing.

An Zong-quan who is an associate professor, having master degree, also appreciates for the Hefei Vocational and Technical college.

REFERENCES

[1] Jiao, Yun-jing, Dong Hong, Zhang Hui-ming, et al. Effect

of combustion chamber geometry on combustion process in spark ignition natural gas engine[J]. Chinese Internal Combustion Engine Engineering, 2009, 30(4): 28~33.

[2]Zheng, Zun-qing, YAO Ming-fa, LIN Zhi-qiang, et al.

Development of Combustion System of an Electric Controlled Lean Burn CNG Engine for Meeting China

Stage Ⅳ Emission Regulations[J]. Chinese Internal

Combustion Engine Engineering, 2009, 30(5): 7~11.

[3]Tomita E, Nobuyuki K, Piao Z Y. et al. Effects of EGR and

early injection of diesel fuel on combustion characteristics and exhaust emissions in a methane dual-fuel engine[C]. SAE Paper 2002012723, 2002.

[4]Simon K, Chen. Gas engine combustion principle and

applications[C]. SAE Paper 2001012489, 2001.

[5]Chengji Zuo, Junhua Zhao. Development of Diesel Engines

Fuelled with Natural Gas[C]. SAE Paper 2001013505, 2001.

[6]Krisada Wannatong, Nirod Akarapanyavit, Somchai

Siengsanorh. Combustion and Knock Characteristics of Natural Gas Diesel Dual Fuel Engine[C]. SAE Paper 2007012047, 2007.

[7]Roussos G. Papagiannakis, Dimitrios T. Hountalas,

Constantine D. Rakopoulos. Combustion and Performance Characteristics of a DI Diesel Engine Operating from Low to High Natural Gas Supplement Ratios at Various Operating Conditions[C]. SAE Paper 2008011392, 2008.

[8]Amrit Singh, David Anderson, Mark Hoffman. An

Evaluation of Knock Determination Techniques for

Diesel-Natural Gas Dual Fuel Engines[C]. SAE Paper

2014012695, 2014.

[9]Hideyuki Ogawa, Peilong Zhao, Taiki Kato. Improvement