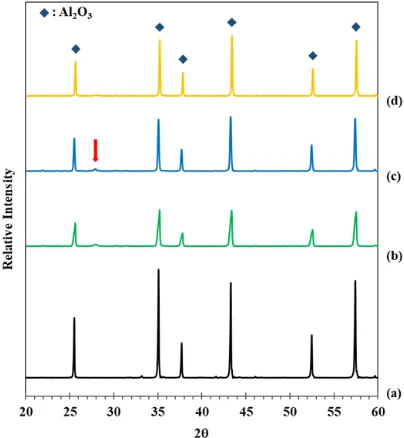

Effect of the Sintering Temperature on the Fabrication of Alumina Beads

Full text

Figure

Related documents

In our previous work 16 , we developed three sculpting tools ( 3D eraser , 3D digger and 3D clipper ) following the virtual hand interaction technique, using

Eight normal infants were studied before and after administration of ammonium chloride. and MO.) fed either evaporated milk diluted with an equal volume of water or homogenized

1) Providing lift core as shear wall is always beneficial in order to increase the lateral resistance of building with utilising the lift service of buildings. Location of lift

[ 41 ] for cryopreservation of the diverse genetic resources of the genera Musa and Ensete and has been widely used for cryopreservation of a huge number of plant species [ 20

This study aimed to assess the prevalence of anxiety and depression and to identify their associated factors including metabolic components among people with type 2 diabetes..

Coordinated through the market Willingly Elaborate mechanism Communication device Functioning remarkably well. Source: Authors’ graphic

Gunasekaran and Ngai (2008) considered perceived benefits of e-Procurement, perceived barriers of e- Procurement, critical success factors of e-Procurement