PROCESS OPTIMIZATION FOR EXTRACTION OF NATURAL DYE

FROM

M. PHILIPPINENSIS

FRUITS AND ITS APPLICATION ON

DIFFERENT FABRICS

Rakesh Kumar* and Y. C. Tripathi and Prasoon K. Kaushik

Chemistry Division, Forest Research Institute, New Forest, Dehradun – 248006

(Uttarakhand) India.

ABSTRACT

The present study was aimed at optimizing conditions such as material

to liquor ratio (MLR), alkalinity of the extractant and extraction time

for maximum extraction of natural dye from M. philippinensis fruits.

The extracted dye was applied for dyeing different kinds of fabrics

including silk, wool and cotton and colourfastness of dyed fabrics

against various colour-fading factors including light, washing, rubbing,

perspiration, etc. was determined. Also, CIE L*, a*, b*, C*, h0 and K/S values were studied by standard methods. Based on the highest optical

density, the optimum conditions, MLR (8.5 g/100 mL), alkali content

(sodium carbonate 0.3 g/100 mL) and extraction time (70 min) for dye

extraction was determined. Extraction of dye with optimized

parameters resulted in significantly high i.e. 12.8% recovery of natural

dye from the plant as compared to conventional method. Further, different types of dyed

fabrics exhibited high fastness score in the range of 4-5 that signifies their very good to

excellent colourfastness property. The research outcome may contribute to the scale-up of M.

philippinensis fruits dye production and is useful for textile industries. It is also an efficient

approach towards natural dye extraction from the plant. M. philippinensis fruit dye having

high medicinal and antimicrobial activity can be used in production of textiles for medical

application and protective clothing.

KEYWORDS: M. philippinensis, Natural dye, Process optimization, Fabric dyeing, Colourfastness.

Volume 5, Issue 4, 927-945. Research Article ISSN 2277– 7105

*Correspondence for

Author

Rakesh Kumar

Chemistry Division,

Forest Research Institute,

New Forest, Dehradun –

248006 (Uttarakhand)

India.

Article Received on 25 Jan 2016,

Revised on 15 Feb 2016, Accepted on 07 Mar 2016

INTRODUCTION

Dyeing with natural colourants has been one of the oldest techniques practiced by the ancient

human civilization. However, advent of the first synthetic dye changed the situation and

synthetic dyes received faster acceptability due to ease in dyeing, high colourfastness, low

cost and wide range of applications. Nevertheless, production and use of synthetic dyes pose

serious problem to environment and living biota.[1] Water pollution due to discharge of non-biodegradable coloured effluents from dye manufacturing and textile-dyeing has become one

of the major environmental concerns.[2] During the last few decades, use of synthetic dyes is gradually decreasing due to their toxicity, non-biodegradability, associated serious health

hazards like allergic and carcinogenicity and increased environmental awareness. There is a

movement across the world to return to the natural dyes that offer much more advantages

including renewable sources, minimal health hazard, mild reaction conditions, no disposal

problems and harmonization with nature.[3] There is a wide spread interest in the natural dyeing because of their better biodegradability and high compatibility with the environment,

which has prompted researchers to look for eco-friendly dye products.[4] As a result, a number of plants have so far been investigated as a source of natural dyes.[5-9]

Despite several advantages of natural dyes, their world-wide consumption is just 1% of the

synthetic dye due to some technical limitations including low yield, complexity of dyeing

process, limited and non-reproducible shades, blending problems and inadequate fastness

properties.[10] Of which, the major challenge is to increase the yield of natural dyes through proper research intervention. Although the Indian subcontinent possesses large plant

resources, only little has been exploited so far.[11] The present work has been aimed to address this issue through optimization of extraction process to obtain maximum possible quantity of

dye from M. philippinensis.

M. philippinensis Muell. Arg. (Fig.1&2) commonly known as Kamala or Senduri is a large

woody multipurpose tree up to 10-12 meters in height under family Euphorbiaceae, naturally

found in Sal and certain mixed forests and widely distributed throughout tropical India along

with the Himalaya from Kashmir east wards up to 1500 m . It has traditionally been regarded

as a popular dye-yielding plant and a rich source of biologically active compounds.[12] Several medicinal properties are attributed to the plant in Indian System of Medicine. All parts of the

tree can be applied externally to treat parasitic infections of the skin like scabies, ringworm,

antifungal tape worm eye-disease, cancer, diabetes, diarrhoea, jaundice, malaria,

urino-genital infection, swellings of joints from acute rheumatism and testes from suppressed

gonorrhoea, etc.[14] Pharmacological studies have revealed purgative, anthelmintic,[15] antioxidant,[16] insecticidal, anti-microbial,[17-19] anti-lithic [20], antifertility[21], antitumour,[22] heptoprotective [23] activities. On account of its wound healing and antimicrobial properties, M. phillippinensis dye could be used in production of skin friendly protective fabrics. The

plant has been investigated for different groups of phytochemicals including amino acids,

carbohydrates, flavonoids, gum, oil and resins, proteins, phenolic groups, saponins, steroids,

tannins and terpenoids.[24] The chemical constituents such as betulin, friedelin, kamaladiol‐3‐acetate,[25] lupeol, tannic acid, 3α‐hydroxy‐D‐A-friedoolean‐3‐en‐2‐one, 2β‐hydroxy‐D‐A‐friedooleanan‐3‐one and 3α‐hydroxy‐D‐A ‐friedooleanan‐2‐one, were

reported from the stem bark.[26-36]

The colouring matter is present in the red glandular pubescence covering of the ripe capsules

and is usually collected in February-March when the fruits ripen. The granules which cover

the ripe fruit are used in India as a dye (Kamala powder) for textile dyeing. The red granules

are usually separated by beating and shaking the ripe fruits, or by stirring the fruits vigorously

in water when the dye settles down as sediment. The sediment is then collected, dried and

pieces of pericarp and other refuse separated by sifting.[37] The dyeing material, known in trade as Kamala, Kamala Powder or Kamala Dye, is used in the dyeing of silk and wool that

produces a bright orange or flame colour.[38] Kamala dye is insoluble in cold water, slightly soluble in boiling water and freely soluble in alkalies, alcohol and ether forming deep red

solutions. The principal colouring constituents, salmon-coloured rottlerin (C30H28O8) and its

[image:3.595.99.501.333.546.2]yellow isomer, isorottlerin together constitute c. 11 % of the powder. In addition, it also

contains a small amount of homo-rottlerin, a low-melting yellow resin (5%), wax (c. 2%),

traces of a volatile oil, tannins, gum and citric and oxalic acids.[36,39]

The yield of kamala powder is only 1.4-3.7 % of the fruits.[39] Low yield of dye by traditional extraction method makes the product very expensive and commercially unfeasible. Present

research work was designed to address this issue through optimization of extraction process

so as to get maximum possible yield of dye from M. philippinensis fruits.

MATERIALS AND METHODS Plant Materials and Fabrics

Fruits of M. philippinensis were collected from the premises of Forest Research Institute,

Dehradun, India. The collected fruits were properly cleaned and then allowed for air drying in

shade. Pure silk, wool and cotton textile fabrics were purchased from Gandhi Ashram, an

authorized outlet of KVIC Dehradun, India. The fabrics were washed with nonionic detergent

(1% owf) for 30 min, rinsed and dried at room temperature. The scoured material was wetted

in water for 30 min prior to dyeing or mordanting.

Chemical and Analytical

All the chemicals viz., acetic acid, alum, copper sulphate, ferrous sulphate, potassium

dichromate and stannous chloride used as mordants were of L.R. grade and were procured

from local dealers. The optical density (OD) of dye extracts were recorded on a UV-Vis

spectrophotometer [Chemito make (Model 2700)], IR spectra were recorded on a FT-IR

(Shimadzu) spectrophotometer. Colour fastness of the extracted dye on different types of

dyed fabric against washing, light, perspiration and rubbing were measured by using

Laundrometer (Make: Metrex Scientific Instrument (P) Ltd.), Digital Light Fastness Tester

(Make-Labin Scientific Instruments and Calibration Pvt Ltd.), Perspirometer and Crockmeter

(Make-Globe–Tex Industries) respectively. The CIEL*a*b*, hue, chroma and K/S values

were determined on a Reference Bench-top Spectrophotometer (Make-Gretag Mac Beth;

Colour-Eye 7000A).

Optimization of Dye Extraction Parameters

Optimization of the conditions such as combination of plant material and extractant (material

to liquor ratio i.e. MLR), alkali content of the extraction medium and extraction time was

extraction experiment was done in 500 mL beaker containing 100 mL of distilled water with

(0.1g-0.7g) of sodium carbonate (Na2CO3) and different amounts of dried fruits of M.

philippensis ranging from 2-12 g and then heated at 95-980 C for varying time ranging from 15 to 80 minutes. The dye extracts obtained from each of the experiments were cooled,

filtered and made to 100 mL. 1 mL of aliquot from each of the extracts were diluted to 100

mL and subjected to optical density (OD) measurement. Each of the extraction experiments

were replicated thrice. Based on the highest value of OD, optimum values of MLR, alkali

content and time for dye extraction were determined. Natural dye from fruits of M.

philippinensis was extracted using calculated values of MLR, alkali content and time.

Optimization of Dyeing Parameters for Different Fabrics

Natural dye extracted under optimum extraction condition was used for dying silk, wool and

cotton fabrics by using fabric to dye solution ratio 1:20 - 1: 50 for 30-75 min. Dyeing of silk,

wool and cotton samples was done by post mordanting method to produce improved shades

in terms of hue and darkness. The dye bath was set with optimum fabric to dye solution ratio

and was heated maintaining the solution level for optimum time calculated for different

fabrics. The dyeing temperature was maintained at 80-850 C for silk and wool and 95-980 C for cotton. The dye bath was cooled to room temperature and the dyed fabrics were directly

transferred to mordant bath for mordanting.

Mordanting of Dyed Fabrics

Most of the natural dyes are mordant dyes and require a mordant for fixing it to the fabric.

Post mordnating method was adopted for mordantoing of dyed fabrics. Common mordants

like alum, copper sulphate, potassium dichromate, iron salts and tin salts have the affinity for

both dye and fabrics and form an insoluble precipitate in combination with dye on the fibre.

For mordanting of dyed fabrics, optimization of mordant concentration, fabric to mordant

solution ratio and mordanting time were done through series of experimental trials. Varying

concentration (0.25, 0.5, 0.75 and 1.0 %) of different mordants, fabric to mordant solution

ratio (1:20-1: 50) and mordanting time 30, 45 and 60 min for silk and wool and 45, 60 and

75 min for cotton were trialled so as to achieve best possible mordating.

After standardizing the mordanting conditions, the dyed samples were directly immersed in

the mordant bath. Mordanting of dyed fabrics was done as per standardized condition of

fabric to dye solution ratio and time. Mordants used for study were metallic salts like: alum,

like Terminalia chebula fruit pericarp powder and Phyllanthus emblica fruit powder was also

employed for mordanting of dyed textile fabrics. The dyed textile samples mordanted

separately with different mordants were codified as MPD 1 (without mordant), MPD 2

(Alum), MPD 3 (Copper Sulphate), MPD 4 (Ferrous Sulphate), MPD 5 Potassium

dichromate), MPD 6 (Stannous chloride), MPD 7 (Phyllanthus emblica) and MPD 8

(Terminalia chebula). Numeric values are indicative of mordant treatments for the three

types of fabrics i.e. silk, wool and cotton for further studies.

Determination of Colourfastness of Dyed Fabrics

Colourfastness of dyed textile fabrics signifies their resistance by which the fabrics opposes

to changing or losing its shade when subjected to the action of various agents such as light,

washing, rubbing, perspiration, staining of the other textiles, etc. Usually, a textile fabric

faces many external conditions which can affect the colour of the textiles. Therefore the

samples of dyed fabrics were tested for their colour fastness properties against washing, light,

crocking/rubbing and perspiration. Colour fastness of dyed fabrics to light, wash, crocking

and perspiration was carried out by standard methods; IS: 2454: 1985, IS-687:1979 IS-766:

1988 and IS-971: 1983 respectively.[40] The tested samples were assessed against the standard grey scales for change of colour and staining on adjacent and rubbing fabrics, while for light

fastness, comparison up to Blue wool standard 5 was done.

Determination of Colour Coordinates

All the dyed and mordanted silk, wool and cotton samples were tested for their L*, a*, b*,

C*, h0 and K/S values using Reference Bench Top Spectrophotometer. CIE stands for Commission Internationale de l’Eclairage system of colour analysis, an international clearing

house for colour research. The terms, L*, a*, and b* signify respectively the luminosity or

lightness, redness or greenness and yellowness and blueness of a sample. Positive a* stands

for red and negative a* for green where as positive b* stands for yellow and negative b* for

blue. Other aspects, like hue, chroma and K/S ratio of the dyed fabrics were also studied so as

to get a more precise result of the colour coordinates.

Hue

Hue is the attribute by which a sample differs from achromatic (i.e. hueless) colour of same

Chroma

Chroma is the colourfulness of an area judged in proportion to the brightness of a similarly

illuminated area that appears to be white or highly transmitting.

K/S Values

Kubelka-Monk equation defines a relationship between spectral reflectance (R in %) of the

sample and its absorption (K) and scattering (S) characteristics, represented as follows:

[1 – 0.01 R2] K/S =

2[0.01 R]

K/S grows to infinity as reflectance decreases to zero

RESULTS AND DISCUSSIONS

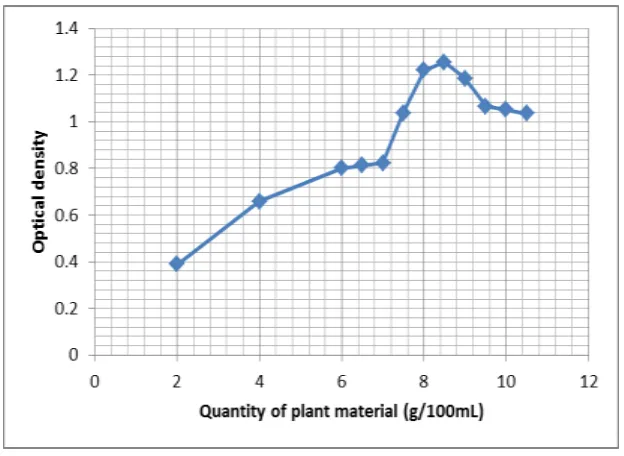

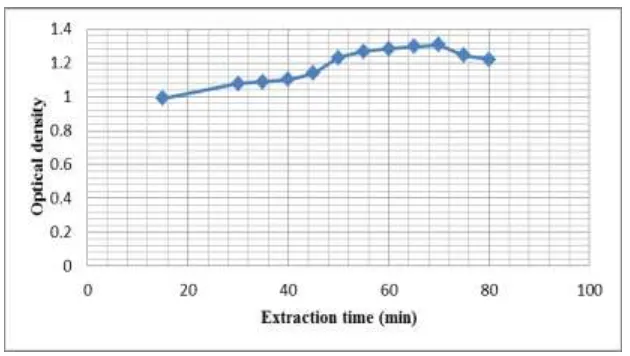

Optimization of Dye Extraction Parameters

Extraction parameters viz., MLR, alkali content and time were optimized based on optical

density (OD) of extracted dye with different levels of the three variables. The highest optical

density 1.256, 2.471 and 1.306 was recorded for MLR of 8.5 g/100 mL (Fig. 3), alkali

[image:7.595.142.454.428.656.2]content of 0.3 g/100 mL sodium carbonate (Fig. 4) and extraction time of 70 min (Fig. 5).

Fig. 4: Standardization of alkali content (pH)

Figure 5: Standardization of extraction time

Based on the highest optical density the optimum conditions MLR (8.5 g/100 mL), alkali

content (sodium carbonate 0.3 g/100 mL) and extraction time (70 min) for extraction of dye

from fruits of M. philippinensis was determined.

Dye Yield with Optimum Extraction Condition

Natural dye was extracted from M. philippinensis with optimized condition of MLR,

alkalinity of extractant and extraction time. The yield of the dye was recorded to be 12.8 %

on moisture free basis. It is, therefore obvious that the yield of natural dye obtained under

optimized conditions is considerably high as compared that obtained by traditional extraction

method.

Dye Absorptivity and Dyeing of Fabrics

Experimental trials were carried out to determine optimal quantity/concentration of dye

[image:8.595.141.456.281.459.2]0.4, 0.6, 0.8, 1.0, 1.2 and 1.4 g/100 mL of dye solution was recorded to be 38.35, 39.83,

41.67, 43.63, 43.86, 34.20 and 32.26 % for silk; 31.32, 32.86, 34.63, 36.86, 43.20, 35.14 and

30.34% for wool and 24.07, 27.57, 22.79, 31.60, 32.92, 29.56 and 27.94% for cotton

respectively. It is evident from absorption percentage data; maximum absorption took place

in case of 1.0g/100mL of dye solution for all the test fabrics i.e. silk (43.86 %), wool

(43.20%) and cotton (32.92%).

Dyeing and Mordanting of Fabrics

Dyeing of silk and wool with M. philippinensis dye was carried out in 1.0 % dye solution

with material to liquor ratio of 1:40 for 45 minutes at a temperature of 80-850 C, while cotton fabric was dyed with the same MLR at 90-950C for 60 minutes. Mordant concentration of 0.5 g/100 mL and mordanting time 30 minutes for silk and wool and 45 minutes for cotton were

found to be optimum by visual observations of dyed and mordanted samples. The criteria for

evaluation were the depth of colour, evenness of dye and brightness of shade. The dyed

samples were directly immersed in the mordant bath by keeping the fabrics to liquor ratio of

1:40. The bath was heated to a temperature of 80-850C for 30 minutes for fixing the dye on silk and wool samples. For cotton samples the mordanting was continued for 60 minute at a

temperature of 95-980C. The samples were taken out from the cooled bath, washed with water and dried in shade. Mordants including metallic salts viz., alum, copper sulphate,

ferrous sulphate, potassium dichromate, stannous chloride and two natural mordants,

Phyllanthus emblica and Terminalia chebula were used for mordanting experiments.

Determination of Colourfastness of Dyed Fabrics

Different types of fabrics i.e. silk, wool and cotton, dyed using M. philippinensis dye were

subjected to colour fastness studies against washing, perspiration, rubbing and light and

determination of colour coordinates including CIEL*a*b* and K/S values as per Indian

Standards (IS).

Colourfastness to Washing

The data regarding colourfastness of dyed and mordanted fabrics to washing are given in

Table 1. The data showed that change in colour on grey scale in silk fabrics in sample

MPD1, MPD2, MPD3, MPD5, MPD6, MPD7 and MPD8 were 4-5 and in MPD4 it was 4/5.

In wool MPD1, MPD2, MPD4 and MPD6 were 4 and in MPD3, MPD5 and MPD7: 4-5

while MPD8 exhibited 3-4. In cotton the change in colour on grey scale in MPD1, MPD2,

respectively. Staining on adjacent fabrics 1 and 2 and in silk, wool and cotton was 4-5 in all

the samples.

Table 1: Colourfastness to washing (As per IS 687: 1979)

The data of colourfastness to washing properties indicate that the washing fastness of silk and

wool is very good to excellent in all the samples however due to weaker affinity of dye with

cotton fabrics the washing fastness is lower in cotton fabrics in comparison with silk and

wool fabrics.

Colourfastness to Light

Colour change of the dyed fabric samples were assessed against the grey scale and the blue

wool standard 5. Light fastness values of all dyed and mordanted samples of silk, wool and

[image:10.595.99.493.134.325.2]on grey scale as well as blue wool scale are summarized in Table 2.

Table 2: Colourfastness to light method (As per: IS: 2454: 1985) S. No Test

Fabric

Change in Colour of Test Fabric on Blue Wool Standard

Silk Wool Cotton

1. MPD1 4 4 3-4

2. MPD2 4 4 4

3. MPD3 4 4 4

4. MPD4 4 4 4

5. MPD5 4 4 4

6. MPD6 4 4 4

7. MPD7 4 4 3-4

8. MPD8 3-4 4 4

The data revealed that change in colour of test fabric on blue wool standard of silk fabrics for

fabrics exhibited change in colour of test fabric on blue wool standard: 4 for the test

specimens viz. MPD1, MPD2, MPD3, MPD4, MPD5, MPD6, MPD7 and MPD8. However

cotton fabrics exhibited lower rating of colour fastness to light in comparison with wool and

silk fabrics. Various tests of light fastness of natural plant based dyes have shown that the

majority have a maximum rating of four (4).[41-43] Results of this study therefore are in conformity with the minimum performance requirements for application of the dye in textile

industry.[44]

Colourfastness to Rubbing

Determination of colourfastness of silk, wool and cotton samples to rubbing and their staining

on adjacent fabrics 1 and 2 was carried out in dry and wet conditions. The staining of the

rubbing fabrics were assessed with grey scale for assessment of staining. The results of

rubbing fastness studies presented in Table-3 revealed that silk fabrics under dry and wet

rubbing test showed 4-5 and 4/5 for all the test samples viz. MPD1, MPD2, MPD3, MPD4,

[image:11.595.78.515.406.569.2]MPD5, MPD6, MPD7 and MPD8.

Table 3: Colourfastness to rubbing (as per IS: 766: 1988) S. No. Test

Fabric

Staining on rubbing cloth Dry rubbing

Staining on rubbing cloth Wet rubbing

Silk Wool Cotton Silk Wool Cotton

1. MPD1 4-5 4-5 4 4-5 4-5 4

2. MPD2 4/5 4-5 4-5 4/5 4/5 4-5

3. MPD3 4-5 4 4-5 4-5 4-5 4-5

4. MPD4 4-5 4-5 4 4/5 4-5 4

5. MPD5 4-5 4-5 4 4-5 4-5 4-5

6. MPD6 4/5 4-5 4-5 4/5 4/5 4-5

7. MPD7 4-5 4-5 4 4-5 4-5 4-5

8. MPD8 4-5 4-5 4-5 4-5 4-5 4-5

Dry rubbing of test fabrics of wool: MPD1, MPD2, MPD4, MPD5, MPD6, MPD7, MPD8

MPD3 exhibited 4-5 while MPD3 exhibited: 4. Rubbing in wet conditions wool fabrics

exhibited 4-5 and 4/5 for all the test samples. Dry rubbing of cotton revealed the rubbing

fastness of 4-5 for MPD2, MPD3, MPD6, MPD8; while dry rubbing fastness for MPD1,

MPD4, MPD5, MPD7, were 4. Colourfastness to rubbing under wet conditions, cotton

fabrics showed 4-5 for MPD2, MPD3, MPD5, MPD6, MPD7, MPD8; and 4 for MPD1 and

MPD4. Silk and wool fabrics exhibited better rubbing fastness properties over cotton. Good

rubbing fastness indicated no unfixed dyes left on the fibre surface after soaping and

fibres, associated with ionic interactions or hydrogen bonding or by complexation with

mordant or with functional groups of dyes.[45]

Colourfastness to Perspiration

Dyed samples were tested for their colourfastness against perspiration (Table-4).

Table 4: Colourfastness to perspiration (Silk) As per IS 971: 1983

Colour change on grey scale and staining on adjacent fabric 1 & 2 by acidic perspiration on

silk indicated that colour change for test sample of MPD2, MPD4, MPD5, MPD7 and MPD8

exhibited colourfastness of 4-5; MPD1 and MPD6: 4 and MPD3: 4/5. Staining on adjacent

fabrics-1 were 4-5 in the case of test sample MPD1, MPD2, MPD4, MPD5, MPD7, MPD8;

MPD3 exhibited 4/5 rating and MPD6 exhibited 4 on grey scale. Staining on adjacent

fabrics-2, the rating for all the samples were 4-5 except MPD3 in which it was 4/5. In

alkaline perspiration change of colour on grey scale were found to be 4-5 for test samples

MPD1, MPD2, MPD5, MPD6, MPD7, MPD8, and 4/5 for test samples MPD3 and MPD4.

The staining on adjacent fabrics 1 and 2 was 4-5 and 4/5 for the all test sample under

investigation.

For wool samples (Table-5) the change in colour on grey scale in acidic perspiration, the

rating for test samples: MPD2, MPD4, MPD5, MPD7, MPD8 were 4-5; MPD3: 4/5; MPD1,

Table 5: Colourfastness to perspiration (Wool) as per IS 971: 1983

Change in colour on grey scale in alkaline perspiration, the colourfastness were 4-5, 4-5, 4/5,

4/5, 4-5, 4, 4-5 and 4-5 for the test samples MPD1, MPD2, MPD3, MPD4, MPD5, MPD6,

MPD7 and MPD8 respectively. The staining on adjacent fabrics 1 and 2 was 4-5 and 4/5 for

the all test sample of alkaline perspiration.

Cotton fabrics exhibited change in colour on grey scale for test sample MPD1 and MPD6-4;

MPD3-4/5 and for rest of the samples: 4-5 (Table-6).

Table 6: Colourfastness to perspiration (Cotton) as per IS 971: 1983

Staining on adjacent fabrics 1 and 2 were 4, 4-5 and 4-5 for all the test samples. The data of

perspiration fastness specify the very good colour fastness to perspiration for silk, wool and

cotton fabrics which are acceptable for textile dyeing.

CIEL*a*b* and K/S Values of Dyed Fabrics

CIEL*a*b* and K/S values of dyed silk, wool and cotton fabrics are summarized in Table 7

The values of L*, a* and b* dyed silk fabrics was calculated as L*: 45.68, 44.89, 49.42,

29.18, 42.25, 49.60, 45.56 and 46.40; a*: 10.35, 9.08, 8.99, 2.74, 10.89, 9.32, 9.53 and 9.17;

b*: 26.78, 25.82, 28.59, 9.43, 28.12, 27.01, 25.47 and 26.09 for MPD1, MPD2, MPD3,

14.84, 16.02, 16.87, 15.52, 12.95, 15.20 and 14.62. The data for variation in ‘L’ values

indicated maximum dark shade (L=29.18) in MPD4 which is mordanted with ferrous

sulphate in silk. Highest value of redness (a*=10.89) in silk was obtained by mordnated with

potassium dichromate (MPD5) while highest value of yellowness (b*=28.59) in silk was

obtained by mordanting with copper sulphate (MPD3). K/S value (16.87) in silk fabrics was

highest in the sample which was mordanted with ferrous sulphate (MPD4). As per

Kubelka-Monk equation as the value of K/S grows, reflectance decreases thereby absorbance

increases, hence it indicates that MPD4 has maximum absorbance.

Table 7: CIEL*a*b* and K/S values of dyed and mordanted fabrics

S.No. Mordant L* a* b* C* h0 K/S

Silk

1. MPD1 45.68 10.35 26.78 28.71 68.86 15.41

2. MPD2 44.89 9.08 25.82 27.37 70.62 14.84

3. MPD3 49.42 8.99 28.59 29.97 22.54 16.02

4. MPD4 29.18 2.74 9.43 9.82 73.78 16.87

5. MPD5 42.25 10.89 28.12 30.15 68.82 15.52

6. MPD6 49.60 9.32 27.01 28.58 70.96 12.95

7. MPD7 45.56 9.53 25.47 27.20 89.50 15.20

8. MPD8 46.40 9.17 26.09 28.27 71.04 14.62

Wool

1. MPD1 49.74 9.26 27.58 29.09 71.44 18.02

2. MPD2 49.42 8.99 28.59 29.97 72.54 16.02

3. MPD3 38.13 5.60 22.72 23.40 76.16 23.16

4. MPD4 29.68 1.12 8.76 8.83 82.72 21.74

5. MPD5 32.91 8.68 25.43 26.87 71.14 29.68

6. MPD6 52.64 9.55 30.75 32.20 72.75 17.74

7. MPD7 44.24 10.26 27.35 29.21 69.43 23.16

8. MPD8 42.42 7.80 24.90 25.16 72.44 18.20

Cotton

1. MPD1 66.29 4.02 16.56 17.04 76.35 4.29

2. MPD2 66.73 3.00 20.41 20.63 81.65 4.00

3. MPD3 60.78 2.98 23.26 23.45 82.69 6.53

4. MPD4 47.91 1.68 7.79 7.97 77.81 6.17

5. MPD5 60.56 4.70 22.56 23.05 78.23 5.74

6. MPD6 71.26 3.55 16.14 16.53 77.58 2.40

7. MPD7 64.03 3.74 17.15 17.55 77.69 4.52

8. MPD8 65.56 3.07 18.77 19.07 80.30 3.98

L*, a* and b* for wool fabrics were L*: 49.74, 49.42, 38.13, 29.68, 32.91, 52.64, 44.24 and

42.42; a*: 9.26, 8.99, 5.60, 1.12, 8.68, 9.55, 10.26 and 7.80; b*: 27.58, 28.59, 22.72, 8.76,

25.43, 30.75, 27.35 and 24.90 for MPD1, MPD2, MPD3, MPD4, MPD5, MPD6, MPD7 and

17.74, 23.16 and18.20 respectively for MPD1, MPD2, MPD3, MPD4, MPD5, MPD6, MPD7

and MPD8. The values of L* indicate that dyed wool fabric, mordanted with ferrous sulphate

(MPD4) has maximum dark shade (L=29.68) which is close to silk fabric. Highest values of

redness (a*=10.26) and yellowness (b*=30.75) was in wool fabrics in MPD7 and MPD6

respectively. K/S values for wool fabrics were 18.02, 16.02, 23.16, 21.74, 29.68, 17.74, 23.16

and18.20 for MPD1, MPD2, MPD3, MPD4, MPD5, MPD6, MPD7 and MPD8 respectively.

It shows that MPD5 has maximum absorbance in wool fabrics.

Cotton fabrics appear less dark than silk and wool. The data of L*a*b* and K/S for cotton

fabrics are:- L*: 66.29, 66.73, 60.78, 47.91, 60.56, 71.26, 64.03, and 65.56; a*: 4.02, 3.00,

2.98, 1.68, 4.70, 3.55, 3.74 and 3.07; b*: 16.56, 20.41, 23.26, 7.79, 22.56, 16.14, 17.15 and

18.77; K/S: 4.29, 4.00, 6.53, 6.17, 5.74, 2.40, 4.52 and 3.98 for MPD1, MPD2, MPD3,

MPD4, MPD5, MPD6, MPD7 and MPD8 respectively. Analysis of the data indicate that

cotton fabric mordanted with ferrous sulphate (MPD4) has darkest shade (L=47.91). Highest

values of redness (a*=4.70) and yellowness (b*=23.26) in cotton fabrics was in MPD5 and

MPD3 respectively.

CONCLUSION

In the present study the extraction procedure for extraction of natural dyes from M.

philippinensis fruits was optimized leading to significantly high recovery of natural dye from

the plant as compared to conventional method. Different kind of fabrics including silk, wool

and cotton dyed with extracted dye exhibited excellent fastness properties against various

colour-waning factors, thus establishing commercial significance of the dye. A systematic

study of extraction and characterization of the M. philippinensis fruits dye is must to

minimize the cost investment, yield maximization and dye purity. The research outcome may

contribute to the scale-up of M. philippinensis fruits dye production useful for textile

industries. Further, the overall research effort is also a very good example of efficient

approach towards extraction operation in the area of natural dye production.

On account of their environment friendliness and non-toxicity to living biota, natural dyes are

gaining world-wide acceptance. However, dye manufacturing units and industries using

natural dyes are facing raw material crisis and availability of limited range of colours. The

outcome of the research work has led to the development of protocol for extraction of dye in

higher yield from M. philippinensis fruits exhibiting tremendous fastness traits on different

philippinensis fruit dye have high medicinal value in general and antimicrobial activity in

particular, thus can be used in production of textiles for medical application and protective

clothing.

ACKNOWLEDGEMENTS

Authors would like to express sincere gratitude to the Director, Forest Research Institute,

Dehradun, India for providing necessary facilities. Authors are also thankful the Indian

Council of Forestry Research and Education (ICFRE, an autonomous body under

MoEF&CC, Govt.of India), for funding support.

REFERENCES

1. Uddin MG, Ghosh NC, Reza MS. Study on the performance of ecoalkali in dyeing of

cotton fabric with reactive dyes. International Journal of Textile Sciences, 2014; 3:

51-58.

2. Patil PD, Rao CR, Wasif AI. Revival of natural dyes: Smart use of biodiversity.

Colourage., 2012; 10: 33-38

3. Teli MD, Paul R, Pardeshi PD. Natural Dyes: Classification, chemistry and extraction

methods, Part–I: Chemical classes, extraction methods and future prospects. Colourage.,

2000; 47(12): 43-48.

4. Prusty AK, Das T, Nayak A, Das NB. Colourimetric analysis and antimicrobial study of

natural dyes and dyed silk. J. Cleaner Prod., 2010; 18: 1750-1756.

5. Dayal R, Dobhal PC. Natural dye from Indian Plants. Colourage, 2001; 48(8): 33-38.

6. Harivaindaran KV, Rebecca OPS, Chandran S.. Study of optimal temperature, Ph and

stability of dragon fruit (Hylocereus polyrhizus) peel for use as potential natural

colorant. Pak. J. Biol. Sci., 2008; 11: 2259-2263.

7. Mansour HF, Gamal AM. Environmental assessment of osage orange extraction and its

dyeing properties on protein fabrics Part I: Standardization of extraction. J. Environ. Sci.

Technol., 2011; 4: 395-402.

8. Boyo AO, Shitta MBO, Oluwa T, Adeola S. Bitter leaf (Vernonia amygdalin) for dye

sensitized solar cell. Trends Applied Sci. Res., 2012; 7: 558-564.

9. Sinha K, Saha PD, Ramya V, Datta S. Improved extraction of natural blue dye from

butterfly pea using microwave assisted methodology to reduce the effect of synthetic

10. Sekar N. Application of natural colourants to textiles– principles and limitations.

Colourage, 1999; 46(7): 33-34.

11. Gulrajani ML. Present status of natural dyes. Indian Journal of Fibre and Textile

Research, 2001; 26(12):191-201.

12. Sharma J, Varma R. Historical review on Mallotus philippienensis (Lam.) M.Arg.

endangered plant. International Human Research Journal, 2014; 2(2): 1-9.

13. Gangwar M, Dalai A, Chaudhary A, Tryambak D, Singh SK, Goel RK, Nath G. Study

on activity of alcoholic extract of glands and hairs of fruits of M. philippinensis in

murine cestodal infection model. International Journal of Pharmacy and Pharmaceutical

Sciences, 2012; 4: 643-645.

14. Zafar R, Yadav K. Pharmacognostical and phytochemical investigations on the leaves of

M. philippinensis Muell. Arg., Hamdard Medicus, 1993; 36(3): 41-45.

15. Verma P,GuptaSS, Aggarwal SK. Purgative and anthelmintic activity in Mallotus

philippinenesis. Ind. J. Pharmacol., 1983; 13(1): 103.

16. Muhammad Arfan, Hazrat Amin, Karamać Magdalena, Kosińska Agnieszka,

Wiczkowski Wiesław and Amarowicz Ryszard. Antioxidant activity of phenolic

fractions of M. philippinensis bark extract. Czech Journal of Food Sciences., 2009; 27:

109-117.

17. Moorthy K, Srinivasan K, Subramanian C, Mohanasundari C, Palaniswamy M.

Phytochemical screening and antibacterial evaluation of stem bark of M. philippinensis

var. Tomentosus. African Journal of Biotechnology, 2007; 6: 1521-1523.

18. Sharma A, Chandraker S, Patel VK, Padmini R. Antibacterial activity of medicinal

plants against pathogens causing complicated urinary tract infections. Indian Journal of

Pharmaceutical Sciences, 2009; 71: 136-139.

19. Velanganni J, Kadamban D, Tangavelou AC. Phytochemical screening and antimicrobial

activity of the stem of Mallotus philippinensis (Lam.) Muell. Arg. Var. Philippensis

(Euphorbiaceae). International Journal of Pharmacy and Pharmaceutical Sciences, 2011;

3(2): 160-163.

20. Gupta SS, Verma P. Lithontriptic effect of M. philippinensis Muell.Arg. (Kamala). J .

Res. Ayur. Siddha, 1989; 10(3): 175-178.

21. Thakur SC, Thakur SS, Chaube SK, Singh SP. An ethereal extract of Kamala (M.

philippinensis (Moll.Arg) Lam.) seed induce adverse effects on reproductive parameters

22. Arya Vikrant. A Review on Anti-Tubercular Plants. International Journal of PharmTech

Research CODEN (USA), 2011; 3: 872-880.

23. Ramakrishna S, Geetha KM, Bhaskar Gopal PVVS, Ranjit Kumar P, Charan Madav P,

Umachandar L. Effect of Mallotus philippienensis Muell. Arg leaves against

hepatotoxicity of Carbon tetrachloride in rats. International Journal of Pharma Sciences

and Research, 2011; 2: 74-83.

24. Kadam VB, Ahire PP. Biochemical evaluation of three endangerd taxa of south Gujrat

forest. Plant Archives. 2007; 7: 897-898.

25. Nair SP, Rao JM. Kamaladiol‐3‐acetate from the stem bark of M. philippinensis.

Phytochemistry, 1993; 32: 407‐409.

26. Bandopadhyay M et al. Triterpenoid and other components of M. philippinensis,

Euphorbiaceae. Phytochemistry, 1972; 11: 1511.

27. Ahluwalia VK, Sharma ND, Mittal B, Gupta SR. Novel prenylated flavonoids from M.

philippinensis Muell. Arg., Indian J. Chem., 1988; 27B(3): 238-241.

28. Saijo, R. et al. Tanins and related compounds. LXXXVIII. Isolation and characterization

of hydrozable tannins from Mallotus japonicum (Thumb) Muller Arg., Mallotus

philippensis (Lam.) Muller Arg., Chem. Pharm. Bull., 1989; 37: 2940-2947.

29. Tanaka T, Ito T, Iinuma M, Takahashi Y, Naganawa H. Dimeric chalcone derivatives

from Mallotus philippienensis. J. Phytochemistry, 1998; 48(8): 1423-1427.

30. Pandey BP. People and Plants of India: Tannins and Dyes. New Delhi: S. Chand &

Company Ltd, 1981.

31. Cragg GM, Newman DJ. Biodiversity: A continuing source of novel drug leads. Pure

Appl Chem., 2005; 77: 7‐24.

32. Khare CP. Indian Medicinal Plants: An Illustrated Dictionary. Germany:

Springer‐Verlag Berlin/Heidelberg, 2007.

33. Reiko T, Tomoko N, Chiharu Y, Shun‐Ichi W, Takeshi Y, Harukuni T. Potential

Anti‐Tumor‐Promoting activity of 3a‐Hydroxy‐D: A‐friedooleanan‐2‐one from the Stem

Bark of Mallotus philippensis. Planta Medica, 2008; 74: 413‐416.

34. Rivie`re Hoai N, Dejaegher B, Tistaert C, Nguyen Thi T, Kim J, Quetin-Leclercq.

Mallotus species from Vietnamese mountainous areas: Phytochemistry and

35. Likai Xia.,Young Rok Lee. Efficient Synthesis of Biologically Interesting Natural

Pyranochalcones from Mallotus philippienensis and Their Unnatural Derivatives.

Bull.Korean Chem. Soc., 2011; 32(8): 2921-2927.

36. Gangwar MR. Goel RK, Gopal N. M. philippinensis Muell. Arg (Euphorbiaceae):

Ethnopharmacology and Phytochemistry Review. Bio. Med. Research International,

2014; 1-13.

37. The Ayurvedic Pharmacopoeia of India, Part-I. Department of AYUSH, Ministry of

Health and Family Welfare, Govt. of India, New Delhi, 1989; 1: 55.

38. The Wealth of India, Raw Materials, Vol. VI. Publications and Information Directorate,

CSIR, New Delhi, 1992; 229-233.

39. The Wealth of India. A Dictionary of Indian Raw materials & Industrial Products. First

supplement series (Raw materials), (J-Q), National Institute of Science Communication

and Information Resources (CSIT-NISCAIR), New Delhi, 2003, 9-32.

40. Handbook of Textile Testing, 1989; 4(15-4): 127, 137,157 & 193.

41. Tim P, Sheila L. The lightfastness of the natural dyes. Stud. Conserv, 1966; 11(4):

181-198.

42. Kunio Y, Patricia CC. Characteristics of fading of wool cloth dyed with selected natural

dyestuffs on the basis of solar radiant energy. Dyes & Pigments, 2003; 58: 199-204.

43. Patricia CC The fading rates of some natural dyes. Stud. Conserv, 1987; 32(2): 65-72.

44. Kadolph JS. Identification of plant residue with commercial potential as natural

dyestuffs. Leopald Centre for Sustainable Agriculture Progress Report, Iowa State

University, 2005; 14: 56.

45. Anna H, Christian RV. The potential use of organically grown dye plants in the organic

textile industry. Experiences and Results on the Cultivation and Yields of Dyers

chemimile (Anhemis tinctoria L.), Dyers Knotweed (Polygonum tinctoria Ait) and Weld