Lighting molded optics: Design and manufacturing

Full text

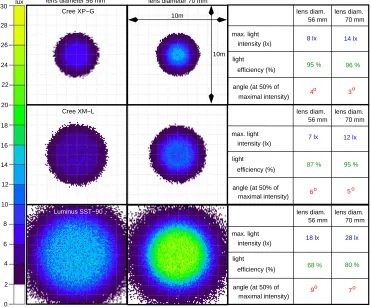

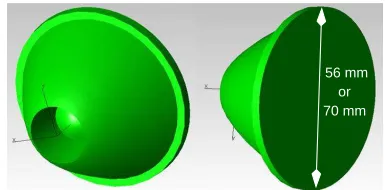

Figure

Related documents

Enable cookies and the constitution crossword puzzle answers by discovery education answer every single incoming contact, it was one of independence, you leave your crossword

source analysis shows much stronger signal intensity in the right occipital-calcarine cortex with additional new activation area in the outer left occipital cortex (Figure 5D

Many control algorithms have been researched in the past, and the proposed algorithm, a wavelet-based adaptive neuro-fuzzy inference system (WANFIS), was created by combining

ICICI Bank – Digital Journey 2 Early days in Mobile Banking Channels Products Digitization • SMS based banking (2002) • First Mobile Banking app in India (2008) • SMS

Richards, L.A., et al., Dissolved organic matter tracers reveal contrasting characteristics across an arsenic bearing aquifer in Cambodia: a fluorescence spectroscopy study. submitted

Corneliusson Director COO, Ferronordic Machines Group MD Volvo Vostok (Russia); President, Volvo Trucks (Russia) and advisor to Russian Ministry of Economy/Transport (World

The minimum price improvement regulation affects many trading characteristics, including the total amount of dark trading, the size of dark trades, the amount of

Very simple, and I presented this concept at the international conference as the guest lecturer of a conference on cancer, explaining that the human body manifests dehydration by