Fiber Bragg Gratings for Strain and Temperature Measurements in a Smart Tire

Full text

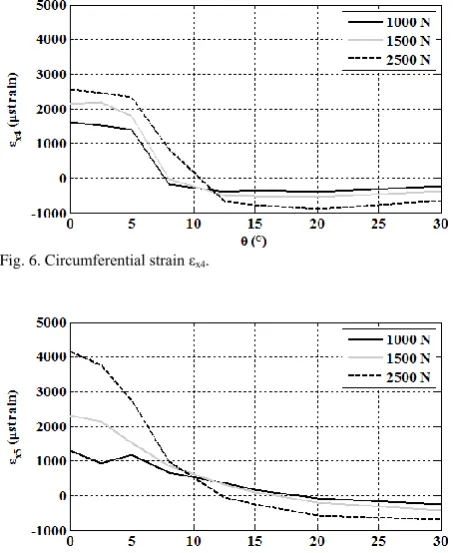

Figure

Related documents

71 Despite the developments in preparation of Mn 2+ doped II-VI nanoparticles employing different transition metal chalcogen complexes as precursors,.

on distribution systems described in section 3, a more precise descriptive model of the system could be obtained. For distributed generation units a machine model must be

A comprehensive revisal of reported studies imply that the thermal performance of double pass solar air heaters with packed bed material in the upper channel

All authors contributed to this project and article equally. All authors read and approved the final manuscript. Middle cerebral artery Doppler indices better predictor for

3) Difference between efficiency and effectiveness: No amount of efficiency can compensate for failure in leadership. Effective leaders in network marketing focus their

The aims of the present study were to compare pain management strategies in patients undergoing open and minimally invasive colorectal surgical procedures, to analyse pain

White Water Rafting Turkey, Greece, Italy, Outer Hebrides Enjoy a fun filled morning white water rafting through the valleys before a BBQ lunch in the forest..

This issue becomes obvious in the low correlation of higher hydrocarbon gases in shorebased and shipboard datasets (see Additional file 1: Figure S1E for ethane and Additional file