The Analysis of Acoustic Characteristics and

Sound Absorption Coefficient of Needle

Punched Nonwoven Fabrics

Fereshteh Shahani1, Parham Soltani2, Mohammad Zarrebini, PhD11

Isfahan University of Technology, Department of Textile Engineering, Isfahan IRAN

2

Amirkabir University of Technology, Department of Textile Engineering, Tehran IRAN

Correspondence to:

Mohammad Zarrebini email: zarrebini@cc.iut.ac.ir

ABSTRACT

Control of acoustical related phenomenon in environments, such as work place and residential homes, using various textile materials has gained paramount importance. Nonwoven fabrics in general are ideal acoustical insulator due to their high volume-to-mass ratio. This research examined acoustic characteristics of structured needle punched floor coverings in relation to fiber fineness, surface effect, punch density, areal density, and chemical bonding process. Sound absorption of the test samples was measured using the impedance tube method. Results indicate that fabrics produced from finer fibers absorb sound waves more efficiently. It was found that, samples with no surface effect enjoy the maximum sound absorption. This is followed by velour and cord surface effect samples. It was established that, higher levels of punch density and higher areal density caused the noise reduction coefficient (NRC) of the fabrics to be increased. It was also found that chemical finishing adversely affected the sound absorption property of the samples.

Keywords: Normal incident sound absorption coefficient, impedance tube method, fiber fineness, surface effect, punch density, areal density, chemical bonding.

INTRODUCTION

Undesirable and potentially hazardous noises are side effects of a wide range of modern engineering and other processes. Sustained development of new technologies has resulted in the environmental impact of noise to become a major concern. The increasing demand for quietness in building and auditoriums has stimulated the use and development of effective means for noise abatement [1, 2].

High density materials, such as steel, can prevent the transmission of sound very effectively by almost total reflection of the incident sound, thus causing sound pollution. Moreover, the sheer weight and cost of steel materials render them as an inefficient sound insulating material [3]. Currently porous materials such as nonwovens fibrous assemblies are widely used as sound absorptive materials. Nonwoven fabrics are usually manufactured directly from fibers, thus partially or completely eliminating conventional textile operations, such as drawing, roving, spinning, weaving, or knitting. The simplicity of fabric formation, coupled with high productivity and small specific gravity, allows nonwovens to compete favorably with woven or knitted fabrics in terms of performance and cost in applications ranging from simple low cost replacements for more expensive textiles to high-quality textiles [4, 5].

Sound absorption characteristics of nonwoven materials have been the subject of a number of research works [9-16]. Many researchers have explained the dissipation mechanism of sound in fibrous materials [13, 14, 16]. Faulkner [14] proved that when sound passes through porous materials, acoustic energy loss takes place due to frictional losses, momentum losses and temperature fluctuations. Experimental data indicate that the fiber mass, thickness and porosity of the nonwoven fabrics seem to be the most influential factors in this respect [14]. Lee and Joo [1] studied the sound absorption coefficient of nonwoven layers manufactured at different mass per unit areas using recycled polyester fibers of different fineness. It was found that nonwovens with higher proportion of fine fibers dissipate more sound. This causes more resistance due to frictional viscosity as the result of air vibration. It was also established that the sound absorption coefficient of absorptive system incorporating with anisotropic nonwovens is marginally higher than the systems containing isotropic webs in their structure. Koizumi, Tsujiuchi and Adachi [17] reported that incorporation of micro denier fibers less than 1 dpf results in a dramatic increase in acoustical performance of the sound absorptive system. This was reaffirmed by Jayaraman [9] who reported that higher specific surface area associated with lower fiber diameter increases sound absorption of nonwoven fabrics. Tascan and Vaughn [3] investigated the effect of total surface area and fabric density on the acoustic behavior of needled nonwoven fabrics. It was reported that in general, nonwovens manufactured from finer fibers with various cross-sectional shape such as round, trilobal and 4DG were better sound absorbers and insulators than those made from coarser fibers. It was also reported that the needled fabrics manufactured using 4DG and trilobal fibers exhibited better sound insulation property than fabrics made from round fibers. Additionally it was demonstrated that fabric density and total fiber surface area in needle punched nonwoven fabrics tended to improve fabric sound insulation. Work of Narang [15] pointed to existence of a direct correlation between fabric sound absorption property and fiber surface area. It was established that, in the frequency range of 1125-5000 Hz, fibers with serrated cross sections in comparison to round fibers absorb more sound. Shoshani and Yakubov [10] established that in properly designed

nonwoven sound absorbers, porosity increases in the direction that the sound wave propagates. Horoshenkov and Swift [18] reported that while location of the quarter-wavelength peaks is mainly affected by fabric tortuosity, height and width of the peaks are affected by flow resistivity and porosity. It was also established that the value of tortuosity determines the behavior of sound absorbing porous materials at high frequency. Sound absorption characteristics of nonwoven materials in relation to fabric thickness have been thoroughly investigated in the literature [19, 20], where it has been unanimously declared that sound absorption in porous materials is directly dependent on material thickness.

Despite intensive research on acoustic characteristics of nonwoven fabrics, there exists hardly any published work that extends the scope of investigation on the influence of surface effect and chemical bonding on sound the absorption behavior of nonwoven fabrics. Therefore, in order to achieve the objectives of this research, various needled fabrics manufactured at three levels of punch density using different fiber fineness were tested using the impedance tube method. Based on results, the effect of the above fabric structural parameters on sound absorption coefficients of the samples was established.

EXPERIMENTAL

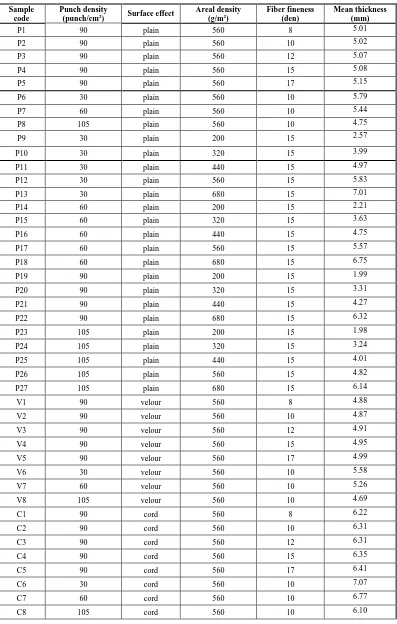

TABLE I. Sample Specification.

Sample code

Punch density

(punch/cm2) Surface effect

Areal density (g/m2)

Fiber fineness (den)

Mean thickness (mm)

P1 90 plain 560 8 5.01

P2 90 plain 560 10 5.02

P3 90 plain 560 12 5.07

P4 90 plain 560 15 5.08

P5 90 plain 560 17 5.15

P6 30 plain 560 10 5.79

P7 60 plain 560 10 5.44

P8 105 plain 560 10 4.75

P9 30 plain 200 15 2.57

P10 30 plain 320 15 3.99

P11 30 plain 440 15 4.97

P12 30 plain 560 15 5.83

P13 30 plain 680 15 7.01

P14 60 plain 200 15 2.21

P15 60 plain 320 15 3.63

P16 60 plain 440 15 4.75

P17 60 plain 560 15 5.57

P18 60 plain 680 15 6.75

P19 90 plain 200 15 1.99

P20 90 plain 320 15 3.31

P21 90 plain 440 15 4.27

P22 90 plain 680 15 6.32

P23 105 plain 200 15 1.98

P24 105 plain 320 15 3.24

P25 105 plain 440 15 4.01

P26 105 plain 560 15 4.82

P27 105 plain 680 15 6.14

V1 90 velour 560 8 4.88

V2 90 velour 560 10 4.87

V3 90 velour 560 12 4.91

V4 90 velour 560 15 4.95

V5 90 velour 560 17 4.99

V6 30 velour 560 10 5.58

V7 60 velour 560 10 5.26

V8 105 velour 560 10 4.69

C1 90 cord 560 8 6.22

C2 90 cord 560 10 6.31

C3 90 cord 560 12 6.31

C4 90 cord 560 15 6.35

C5 90 cord 560 17 6.41

C6 30 cord 560 10 7.07

C7 60 cord 560 10 6.77

FIGURE 1. Surface effect A) plain B) velour C) Cord.

A standard compression tester exerting a constant pressure of 0.1 psi was used to measure sample thickness at 10 different locations. The normal incidence sound absorption coefficients were measured over the frequency range from 250 Hz to 4000 Hz, using the impedance tube method which is not only faster and generally reproducible, but also requires very small circular test samples. In this method, the samples are fastened to one end of tube, and the loud speaker that can emit sound waves of well-defined frequencies is attached to the other end of the tube. The emitted waves travel through the tube and are reflected back from the sample. The reflected waves are received by the microphone. The received waves by the microphone are pictorially shown on the oscilloscope screen [21, 22]. Proportion of sound absorbed by test fabric is calculated using Eq. (1) and Eq. (2).

(

)

2 22 2 2

1 4 1

1 1

n n n

n

p p p

I I

i r i r i

+ =

+ − − = − = =

α

(1)

min max P P

n= (2)

Where

α

is the sound absorption coefficient.i

I and

I

r are intensities of incident and reflectedwaves respectively.

i

P and

P

r denote pressure of incident and reflected waves respectively.n

is the standing wave ratio, which is the ratio of the maximum to minimum pressure of the sound wave.max

P and

P

min are maximum and minimum values of sound wave pressure respectively as shown on the oscilloscope screen [23].Each sample was tested 10 times. In the absence of no peripheral sound, data were taken at an ambient temperature of 23 C° and relative humidity of 55 percent (for more details see [21]).

Usually when materials are used as acoustic barriers the index denoting the acoustic property of the barrier is known as sound absorption coefficient. Another index is known as noise reduction coefficient or NRC which is the arithmetic average of absorption coefficients at frequencies of 250, 500, 1000, 2000 and 4000 Hz. In this work NRC of the samples were also obtained.

RESULTS AND DISCUSSIONS Influence of Fiber Fineness

FIGURE 2. Variation of absorption coefficient with frequency for plain surfaced nonwoven fabrics produced using various fiber fineness.

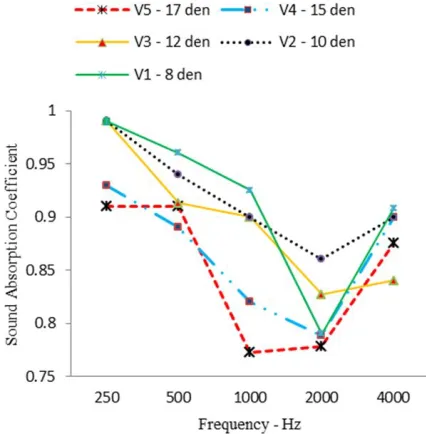

FIGURE 3. Variation of absorption coefficient with frequency for velour surfaced nonwoven fabrics produced using various fiber fineness.

FIGURE 4. Variation of absorption coefficient with frequency for cord surfaced nonwoven fabrics produced using various fiber fineness.

As fiber fineness increase, for a given volume density a higher number of fibers is required. This results in a more tortuous path and higher airflow resistance in the fibrous assembly. Fine fibers also have more chance to contact sound waves; this in turn results in increasing airflow resistance by means of frictional viscosity through the vibration of the air, hence the observed increase in absorption coefficient. Moreover, fine fibers can move readily in comparison to coarse fibers. The ease of movement associated with finer fibers results in rapid conversion of acoustic energy to heat. Furthermore, the presence of fine fibers decreases the probability of pore connectivity which enhances the absorption behavior of nonwoven samples [1, 9].

Influence of Surface Effect

FIGURE 5. Variation of NRC for various surface effects (Areal density 560 g/m2).

Felting needles are used on a needlepunch machine to produce compact webs. As the needle loom beam moves up and down, the working blade of needles penetrates the fibrous batt. Barbs situated on the blade pick up fibers on the downward cycle. The pickup fibers are carried a distance approximately equal to the set needle penetration depth. Thus, the loose batt is converted into a relatively compact nonwoven fabric. Velour and cord surface effects are imparted to the pre-consolidated batt using a structuring needle loom equipped with fork needles. Fork needles transfer fibers from pre-consolidated batt to the surface as velour or cord pile. This action of fork needles effectively produces a dual structure composed of a dense base and a loose surface. NRC of these structured fabrics is lower than that of comparable plain surface samples due to the variation in the porosity of the base and pile section of the fibrous assembly.

The reduction of absorption coefficient at frequency bands of 1000 and 2000 Hz can be due to the coincidence dip phenomenon. This phenomenon is commonly known as the critical frequency which can severely limits sound absorption ability of the sample. The coincidence dip occurs when the incident sound wave is in phase with the reflected wave from the test sample. As can be observed in

Figure 4, at frequency of 250 Hz, cord surfaced samples suffer from low absorption coefficient. It can be attributed to the less compactness of fibers in the pile section of the cord surfaced fabrics which results in transferring the coincident frequency to lower frequency bands.

Influence of Punch Density and Areal Density Figures 6-8 depict variation of absorption coefficient with frequency for plain, velour and cord surfaced fabrics at four different punch density levels.

As can be observed, for the given conditions,the sound absorption coefficient increases up to a punch density of 90/cm2 and then tends to reduce slightly. This trend might be attributed to the higher flow resistivity of samples needled at higher levels of punch density. At high punch density the fabric has high tortuousity, high number of very small size pores and higher fiber to fiber contact areas. Furthermore, at high punch density, fiber entanglemnt within the fabric is increased which in turn leads to production of compact or high density fabrics. The slight decrease observed in sound absorption of samples beyond 90/cm2 punch density may be attributed to increase in fiber breakage which changes the internal balance of fabric tortusity, pores and fiber to fiber contact area. Comparison of NRC of the three types of samples is presented in Figure 9.

FIGURE 7. Variation of absorption coefficient with frequency for velour surfaced nonwoven fabrics produced at different punch density levels

FIGURE 8. Variation of absorption coefficient with frequency for cord surfaced nonwoven fabrics produced at different punch density levels.

Effect of fabric areal density on sound absorption coefficient of plain samples is illustrated in Figure 10. As can be seen, sound absorption coefficient increases with areal density. Referring to Table I, this is due to increase in fabric thickness as areal density increases. It is also observed that at low frequency, sound absorption has a direct relationship with thickness and at high frequency thickness has a modest effect on sound absorption. This is in total

who showed that, in contrast to high frequencies where material thickness insignificantly affects sound absorption property of the porous material, at low frequencies sound absorption increases with increase in material thickness. Experiments conducted using needle punched fabrics of other surface effects such as velour and cord yielded similar results as far as areal density was concerned.

FIGURE 9. Variation of NRC for various surface effects at different punch density.

FIGURE 10. Variation of absorption coefficient with frequency for plain surfaced nonwoven fabrics having different areal densities.

Figure 11 depicts the interaction between needle punch density and areal density and its effects on NRC for plain surface effect samples (Samples P4 and P9-P27). As can be seen, generally thicker samples enjoy higher NRC values. Furthermore, the results indicate that an slight decrease in NRC values of samples with lower areal densities occur as punch

to the fact that for a given needle penetration depth as areal density of the sample decrease not only more fiber breakage occurs, but also fabric density is reduced. However, in case of samples with higher areal density, increase in punch density correspondingly increases fabric compactness and density which results in better sound absorption. Similar results were obtained for samples with velour and cord surface effects.

FIGURE 11. Variation of NRC with neddle punch density for plain nonwoven fabrics having different areal densities (Fiber fineness 15 denier)

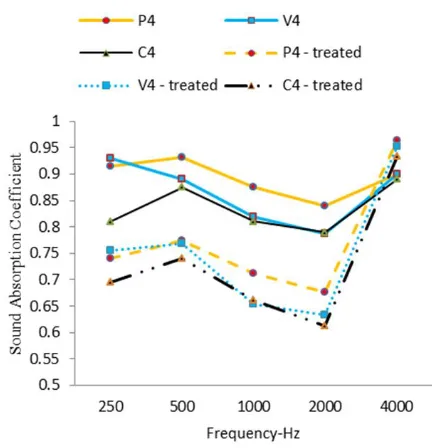

Influence of Chemical Bonding

Sound absorption behavior of the samples after chemical bonding using SBR latex is depicted in

Figure 12. As can be observed, with the exception of 4000 Hz, at other frequencies due to coincidence effect sound absorption coefficient of the bonded samples has noticeably decreased. Furthermore, rigidity of the samples increases due to addition of SBR latex which effectively acts as a sound reflecting barrier. The marked increase in sound absorption at frequency of 4000 Hz is related to the fact that the coated film of SBR latex effectively acts as an added layer that prevents occurrence of coincidence effect at this frequency thus the observed increase in absorption of sound by the samples.

FIGURE 12. Effect of chemical bonding on absorption coefficient.

CONCLUSION

REFERENCES

[1] Lee Y., Joo C. "Sound Absorption Properties of Recycled Polyester Fibrous Assembly Absorbers", AUTEX Res J, Vol. 3, No 2, 2003, 72-77.

[2] Bliss D. B. "Study of Bulk Reacting Porous Sound Absorbers and a New Boundary Condition for Thin Porous Layers ", J Acoust Soc Am, Vol. 71, No 3, 1982, 533-545. [3] Tascan M., Vaughn E. A. "Effects of Total

Surface Area and Fabric Density on the Acoustical Behavior of Needlepunched Nonwoven Fabrics", Textile Research Journal, Vol. 78, No 4, 2008, 289-296.

[4] Wang X. Y., Gong R. H. "Thermally Bonded Nonwoven Filters Composed of Bicomponent Polypropylene/Polyester Fiber. I. Statistical Approach for Minimizing the Pore Size", Journal of Applied Polymer Science, Vol. 101, No 4, 2006, 2689-2699.

[5] Association I. N. D. "Guide to Nonwoven Fabrics", New York: INDA; 1978.

[6] Banks-Lee P., Peng H., Diggs A. L. "The Sound Absorption Properties of Needle Punched Nonwoven Fabrics" in TAPPI Proceedings, Nonwovens. 1992.

[7] Barron R. F. "Industrial Noise Control and Acoustics", New York: Marcel Dekker; 2003. [8] Sides D. J., Attenborough K., Mulholland K. A. "Application of a Generalized Acoustic Propagation Theory to Fibrous Absorbents", Journal of Sound and Vibration, Vol. 19, No 1, 1971, 49-64.

[9] Jayaraman K. A. Acoustical Absorptive Properties of Nonwovens. Raleigh.2005. [10] Shoshani Y., Yakubov Y. "Use of Nonwovens

of Variable Porosity as Noise Control Elements", International Nonwovens Journal, Vol. 10, No 4, 2001, 23-28.

[11] Shoshani Y., Rosenhouse G. "Noise Insulating Blankets Made of Textiles", Applied Acoustics, Vol. 35, No 2, 1992, 129-138. [12] Shoshani Y. "Noise Absorption by

Combinations of Woven and Nonwoven Fabrics", J Text Inst, Vol. 82, No 4, 1991, 500-503.

[13] Wang C., Torng J. "Experimental Study of the Absorption Characteristics of Some Porous Fibrous Materials", Applied Acoustics, Vol. 62, No 4, 2001, 447-459.

[14] Faulkner L. L. "Handbook of Industrial Noise Control", New York: Industrial Press; 1976. [15] Narang P. P. "Material Parameter Selection in

Polyester Fibre Insulation for Sound Transmission and Absorption” Applied Acoustics, Vol. 45, No 4, 1995, 335-358.

[16] Delany M. E., Bazeley E. N. "Acoustic Properties of Fibrous Absorbent Materials", Applied Acoustics, Vol 3, No 2, 1970, 105-116.

[17] Koizumi T., Tsujiuchi N., Adachi A. The Development of Sound Absorbing Materials Using Natural Bamboo Fibers. High performance Structure and Composites: WIT Press; 2002.

[18] Horoshenkov K. V., Swift M. J. "The Effect of Consolidation on the Acoustic Properties of Loose Rubber Granulates", Applied Acoustics, Vol. 62, No 6, 2001, 665-690. [19] Ibrahim L. L., Melik R. W. "Physical

Parameters Affecting Acoustic Absorption Characteristics of Fibrous Materials" in Proceedings of the mathematical and physical society of Egypt. 1978. Egypt.

[20] Hirabayashi T., McCaa D. J., Rebandt R. G., Rusch P., Saha P. "Automotive Noise and Vibration Control Treatments", Sound and Vibration, Vol. 33, No 4, 1999, 22-32.

[21] Soltani P., Zarrebini M. "The Analysis of Acoustical Characteristics and Sound Absorption Coefficient of Woven Fabrics", Textile Research Journal, Vol. 82, No 9, 2012, 875-882.

[22] Soltani, P., Zarrebini M. "Acoustic Performance of Woven Fabrics In Relation To Structural Parameters and Air Permeability", Journal of the Textile Institute, Vol. 104, No 9, 2013, 1011–1016.

[23] Kundt A. "Acoustic Experiments", Philosophical Magazine and Journal of Science, Vol. 35, No 4, 1868, 41-48.

[24] Sun F., Banks-Lee P., Peng H. "Sound Absorption in an Anisotropic Periodically Layered Fluid Satuarted Porous Medium", Applied Acoustics, Vol. 39, No 1, 1993, 65-76.

AUTHORS’ ADDRESSES Fereshteh Shahani

Mohammad Zarrebini, PhD

Isfahan University of Technology Department of Textile Engineering Daneshgah Blvd.

Isfahan 54156-83111 IRAN

Parham Soltani

Amirkabir University of Technology, Department of Textile Engineering Hafez