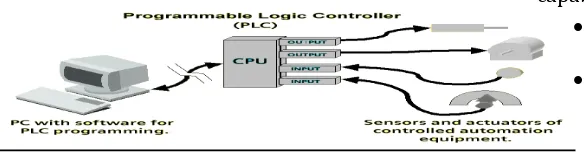

Automation of Bottle Filling System in Industries using PLC AND SCADA

Full text

Figure

Related documents

The “-” line of control voltage source is connected to the “PAR” input terminal and the “+” line of control voltage source is connected to the power supply output

The Central Processor Unit (CPU) for the Series Six Plus Programmable Logic Controller (PLC) contains a power supply, three control modules and a memory module, connected to a

Schema snap in active directory connection server connections connect to the fsmo role you can be nested groups with ldif files are several other remaining settings.. It is

After replacing the water filter, press and hold the Water Filter Replace button for three seconds to turn the indicator light off.. Replace the water filter approximately every

In this study (TABLE 2), significantly higher blood glucose, insulin, triglyceride levels and HOMA-IR value in the obese subjects compared with those in non obese subjects

The primary purpose of this study, therefore, was to test the feasibility and preliminary efficacy of an intervention in which participants were provided (or not provided)

Specification C3.4 contains detailed Deemed-to-Satisfy Provisions that could form part of a Building Solution for achieving the Performance Requirements relevant to:. •

For doing so, employees need to be trained to develop skills needed for a successful service delivery, be informed about and involved in the organization, and be committed