International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 4, Issue 11, November 2014)

306

Distortion Reduction in Gear Heat Treatment Process by a

Simple Fixture

Jeevan P. George

1, Justin Koshy

2, Biju cherian Abraham

31PG Scholar, 2Assistant Professor, 3Associate Professor, Department of Mechanical Engineering, Mar Athanasius College

of Engineering, Kothamangalam, Kerala, India

Abstract— Cooler fan drive gears are used in the MGB for cooler fan to cooling the oil in the ALH Helicopters. The manufacturing of the cooler fan drive gear involves CNC turning, milling, heat treatment and grinding operations etc. The cooler fan drive gear of the ALH helicopter was facing critical problem of rejection when it is heat treating. At the time of quenching the gear is getting distorted due to stresses acting on to the part. In order to reduce the distortion which has occurred during the quenching something need to be done to optimize the process during that time. So by the implementation of the fixture at time of heat treatment and tested it in a batch to saw that distortion could be reduced.

Keywords—heat treatment Process, Gear, Distortion

I. INTRODUCTION

Heat treatment is used to improve some of the mechanical properties of steel components and commonly involves a quenching step which may cause undesired geometric distortions in the processed parts. The dimensional accuracy of these parts is affected and leads to production and economical losses.

An example of this situation is the production of rolled and heat treated rings with large diameters and small thickness, where quenching causes out-of-roundness of rings. Various factors including phase transformation of steel, retained austenite, quench media, severity and uniformity and process selection may influence the final dimension of a quenched part [6].

The plastic deformation of metallic components during heat treatment is referred to as distortion. Distortion occurs if the stress in the material exceeds the yield stress of the material. During case hardening the components are exposed to high temperatures in the range of 880oC to 1050oC and the yield stress decreases strongly with increasing temperature of a component. Three different types of stress in the material need to be distinguished.

1.Residual stresses are induced before heat treatment by casting, forging, machining etc..

2. Thermal stresses are caused by the temperature gradient while heating and quenching.

3.Transformation stresses are caused by the transformation from ferrite to austenite during heating and transformation from austenite to martensite or bainite during quenching.

At the time heat treating the part there will be large deformation during carburizing and quenching processes [7]. The study on the part of cooler fan drive gear is made up of ZFNL 9201 material and its chemical compositions are C (0.15-0.19), Mn (0.4-0.6), Cr (1.4-1.7), Si (max. 0.35) P (max. 0.015), S (0.015), Ni (1.4-1.7), Mo (max 0.1), Cu (max 0.2), Al (max 0.045).

Mechanical properties of material ZFNL9201 are,

Yield strength : 750 N/mm2 Tensile strength : 1100-1500 N/mm2

Elongation : >=7 %

Reduction : >=30%

Charpy work Impact : >=20 J

Use of the fixture can be reducing the distortion in the cooler fan drive gear [1]. The reason may be the inadequate support provided for the gear during heat treatment. Therefore to provide adequate or better support to gear to avoid sagging during heat treatment.

II. LITERATURE REVIEW

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 4, Issue 11, November 2014)

307

Defects and Distortion in Heat-Treated Parts [4] is a hand book, tells about shape distortion or warpage. This is sometimes called straightness or angularity change. It is found particularly in nonsymmetrical components during heat treatment. From the practical viewpoints, warpage in water- or oil-hardening steels is normally of greater magnitude than is size distortion and is more of a problem because it is usually not predictable. Development, Fabrication and Analysis of Fixture [5], this paper deals with the how a fixture is effectively fabricate and its analysis.

III. PROBLEM DEFINITION AND ANALYSIS

[image:2.595.102.498.306.465.2]The cooler fan drive gear is facing the distortion during the heat treatment process. Often the distortion has arise at carburizing and quenching. Both the processes have not been able to meet the specifications because of the improper seating. The cooler fan drive gear is small in size so the number of parts undergoing the process will be high, therefore the batch of operation can be performed. Because of the number of parts in a batch is high, it is very hard to do the heating process in carburizing as well as quenching due to the excess of parts, therefore could not meet the specifications as required.

Figure 1: General fish bone diagram

Due to specifications have not been able to meet at random side of the component it would generate contraction and expansion. By the generation of the contraction and expansion the concentric centre of the circle would differ from its diameter, hence runout generated. After it has completed the heat treatment, comes over the grinding operation. At the time of grinding operation only this defect is formed like as warpage, ovality and unground portions. So due to the formation of these defects it cannot be forwarded for the further operation. This is because distortion of the part during heat treatment. Hence the efforts are made to understand the problem of distortion and find the remedial measures.

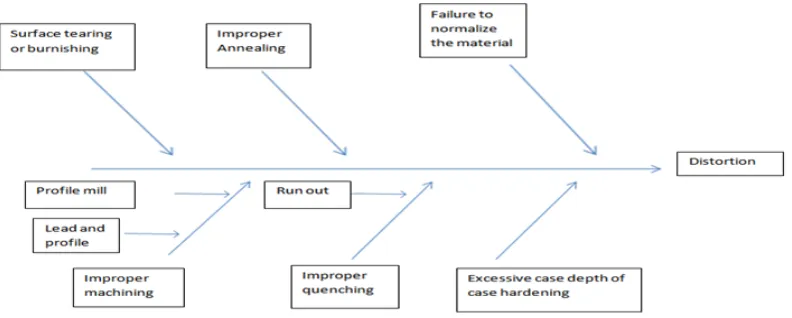

A. General Fishbone Diagram for Distortion

To identify the root causes, the cause and effect diagram has been drawn to find the causes which affect on distortion of the gear. Causes can be derived from brainstorming sessions. These groups can then be labeled as categories of the fishbone. It has find out that different main causes are affecting the gear during the machining operation as well as heat treatment. For this part so far been affected three main problems are runout, profile mill and lead and profile.

In the lead and profile problem has generated due to the grinding wheel. Due to the improper positioning of the grinding wheel this problem had been generated.

The profile mill is the problem has occurred to the four legs of the component which has due to by the milling operation. It has been resolved by the proper milling operation.

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 4, Issue 11, November 2014)

308

B. Data Collection

[image:3.595.46.278.192.424.2]The data given below are the previous batch problems. The data given in the tables are the rejection, acceptation of the part and reason for the rejection of the part as well.

TABLE I DATA COLLECTION

Work order no.

No. of parts

produced Accepted Rejected

Reason for rejection

7512100989 4 1 3

Lead and profile quality measuring

more

7607101792 16 10 6 Runout

7507101248 5 3 2 Runout

7512029880 10 4 6 Profile

mill

The data collection of the cooler fan drive has been taken for previous batches. Out of 35 parts produced, in that 17 got rejected due to various reasons. In the first work order there are 4 parts produced, 3 got rejected due to lead and profile run out measurement is more. Next work order has 16 parts produced, in that 6 got rejected due to run out. Another work order has 5 parts produced, in that 2 got rejected due to run out. Next work order has 10 parts produced, in that 6 parts got rejected due to profile milling operation.

C. Fishbone Diagram for Distortion

The root causes of the distortion for the components are drawn in this fishbone diagram. So far the part been got distorted due to the improper quenching and improper machining. Improper positioning of fixture in the both carburizing as well as quenching were leads to residual stresses are formed on the random side of the component there by improper heating processes causes to get distorted.

Distortion of parts after heat treating is the greatest source of problems for heat treaters distorted parts can lead to potentially early failure due to high residual stresses. Figure 3.2 shows that many sources of residual stress and distortion occur before and during heat treatment.

[image:3.595.315.550.221.419.2]

For example, many processes prior to heat treatment involve material removal such as grinding, broaching, and turning, quenching, carburizing. These operations create a large amount of residual stresses in the part, which are relieved during heat treatment, resulting in part distortion.

Figure 2: Fish bone diagram

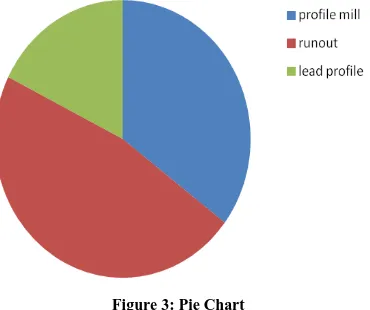

D. Pie Chart

The pie chart has been drawn to classify the reasons and analyze it to execute reason which has most affect the rejection of the gear.

Figure 3: Pie Chart

[image:3.595.342.527.498.653.2]International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 4, Issue 11, November 2014)

309

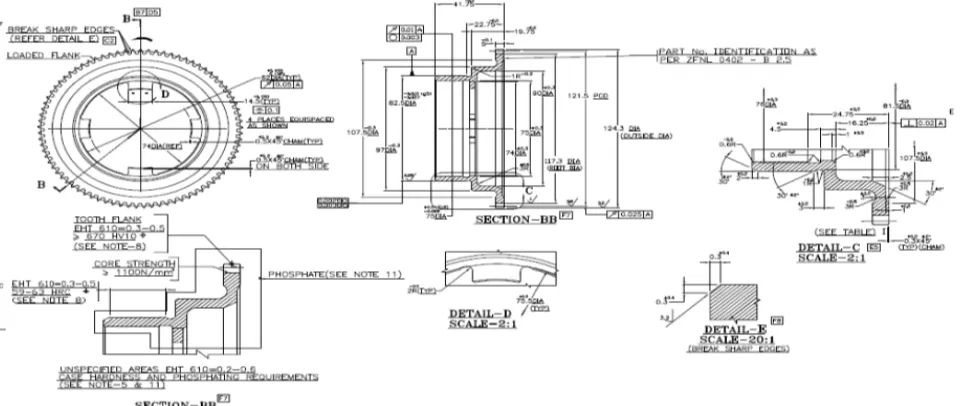

E. Gear Geometry and Measurement Report

According to the geometry, the gear has been manufactured. The measurement report of the gear has been tabulated regarding with the critical dimensions of the part. The readings given in the measurement report are the measurement of the part of critical dimensions, surface finish and hardness values.

[image:4.595.59.539.163.366.2]This report is furnished after the quenching. In that the runout portion of the gear has varied from its within the limit. So the part has been rejected. Other measurements of the part were within the limit of its dimension. The table given below has shown the measurement of the eight parts.

TABLE 2

RUN OUT MEASUREMENT REPORT

The table 3.3 has provided runout dimensions of the part. After the checking of the measurement report. The dimensions of the runout are out of limit. So the particular run out reading has been drawn out in the table.

F. Rectification of Distortion during Quench Hardening

There are some solutions to rectify the distortion problem during heat treatment are given below.

Component design modification- the design of the component is already fixed. Further there is nothing can be changed.

Quenching selection- the quenched used here is the meta- quench oil (SAE 39) especially for the aerospace applications.

Quenching time- the quenching time taken for the component can be vary. But it is unable to obtain the same hardness which required for it.

[image:4.595.130.472.463.637.2]International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 4, Issue 11, November 2014)

310

Without any major amendment to the present treatment like changing the quenchent, changing the material etc. which all are leads to economical changes. A proper fixturing is more suitable to reduce the distortion in the component

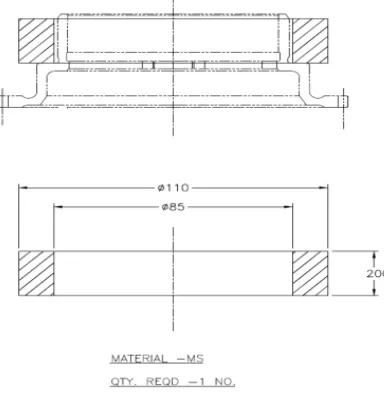

IV. RESULT AND DISCUSSION A. Fixture

The reason for the distortion is the inadequate support provided for the gear during heat treatment. So aim is to provide better or adequate support to gear to avoid sagging during the heat treatment process. After found out the problem, its importance in the suggestion of the fixture and its complete fabrication has comes to evolve at end. When its need at the time of heat treatment is not complex so made of the fixture was easy as well. The fixture has arrest the stresses happened at the time of quenching thereby can reduce the rejection rate. Some important requirements taken into account when designing the fixture were, The material used for the fixture is medium carbon steel(C-45). The material is used in the fixture is harder than the material used in the part. So the stresses act during the time of quenching can be prevented up to a limit. The properties of the material used in the fixture are,

Medium Carbon Steel (C-45)

C - 0.4-0.5

Si - 0.1-0.35

Mn - 0.6-0.9

Two separate blocks are fabricated ALH- 31679(Carburizing) and ALH-31680 (Quenching), one is support the part for carrying out carburizing and other is to load the part for carrying out quenching as well. For the quenching block outer diameter of the component is taken into consideration. For the carburizing the inner diameter of the component is taken into consideration

B. Steps in Fixture Design

Designing a fixture the designer should know the basic steps of design. According to the steps given below the design of the cooler fan drive has been done.

Step 1

• Study of the component: is most important step of the designer to study the important information such as critical measurement, clamp area etc.

Step 2

• Geometrical model of the component: is done by the critical dimension

Step 3

• Selection of tooling material: the material used in the fixture may be varies regarding its application

Step 4

• Solid modelling of tool: 3D modelling of the entire component is done by using unigraphics software

Study of the component has been carried first to understand the material and its property to finalize the design of the fixture. The size and weight are important parameters for considering the design of the fixture. The clamp area, critical measurements are important area of concern. Next step is to understand the geometrical model of the component it is done by the critical dimensions of the component.

In the next step, it is important consider the tooling material or fixture material .this step is most important for design of the fixture, why because the fixture need is in heat treatment. Here the fixture is covered the component in order to prevent the contraction as well as to support the component in the steady position as well. So this step is most important for the designing of the fixture.

Here, the number of fixture need in this heat treatment is two. One of the fixture is need at the time of carburizing operation. It is need to put a dead weight on the component to avert the movement from the vertical position. Otherquenching to prevent direct contact of the quenchent to affect the component. Next step is the designing software, after understand the basic requirement for the fixture for designing, unigraphics selected for the designing the fixture.

C. Fixture for Carburizing

The first fixture for the part is for the carburization process. When doing the carburization process it is heat up to 9000c - 9100c, that time part might have a chance of tilting to any direction thereby it leads to misplacing from its vertical direction so it is need to provide adequate support during its carburizing process.

International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 4, Issue 11, November 2014)

[image:6.595.52.280.116.334.2]311

Figure 5: Fixture for carburizingD. Fixture for Hardening

[image:6.595.314.565.129.333.2]The second fixture is for the hardening process. It includes both hardening as well as quenching. when the part is hardening, it must have to heat up to the 8400c - 8500c.after that the part is taken out for quenching, during the quenching process the part has gone through sudden cooling (800c - 1000c). so due to the sudden cooling the part has some deflection from its original state. To prevent this deflection, it has introduced the second fixture.

Figure 6: Fixture for hardening

The fixture shown below is the fixture used for the heat treatment process of the cooler fan drive gear.

Figure 7: Fixture

[image:6.595.315.549.392.486.2]After the fixture has been implemented and tested it in a batch of operation and done the measurement of the particular runout area.

TABLE 3

RUN OUT MEASUREMENT REPORT

It has seen that the runout of the particular component after the heat treatment was less.

V. CONCLUSION

[image:6.595.63.255.482.680.2]International Journal of Emerging Technology and Advanced Engineering

Website: www.ijetae.com (ISSN 2250-2459,ISO 9001:2008 Certified Journal, Volume 4, Issue 11, November 2014)

312

REFERENCES

[1] Praveen C Gadagkar, Shivappa D. N., Pradeepa shivaswamy (2013) Identification of gear distortion in manufacturing and finding solution using reactive improvement methodology, International Journal of Emerging Technology and Advanced Engineering 3 (8), 2250-2459.

[2] Remi Husson , Jean-Yves Dantan , Cyrille Baudouin , Serge Silvani (2012) Evaluation of process causes and influences of residual stress on gear distortion, 551-554.

[3] Volker Heuer and Klaus Loser (2010) Low Distortion Heat Treatment of Transmission Components

[4] Anil Kumar Sinha, Bohn Piston Division, 1991, Defects and Distortion in Heat-Treated Parts, 601-609

[5] Kiran Valandi, M.Vijaykumar, Kishore Kumar S Development, 2014, Fabrication and Analysis of Fixture,11414-11416

[6] Zirui Panga, Shenjun Yua , Jinwu Xub, 2013, Study of effect of quenching deformation influenced by17CrNiMo6 gear shaft of carburization, 103-112