2017 2nd International Conference on Manufacturing Science and Information Engineering (ICMSIE 2017) ISBN: 978-1-60595-516-2

Application of Improved Genetic Algorithm in

Coiled Material

Guitang Wang, Chaoqiong Yang, Zhisheng Chen

and Yuxiang Zhang

ABSTRACT

In the process of cutting the coil, tend to appear coil are different specifications for raw materials, the required production of different sizes of products, and the number of the corresponding product production is different. in order to improve the utilization of the coil, reduce scrap, A genetic algorithm with improved preference is proposed to solve the problem of optimization of coil cutting. Based on the traditional genetic algorithm, the cutting planning model is established to determine the cutting arrangement of the web to be cut. In order to solve the problem of avoiding the local optimal and premature convergence of the genetic algorithm, adopt the method of generation of father and son to participate in competition to improve the genetic algorithm. The results of statistical analysis show that the improved genetic algorithm can improve the optimization ability and obtain the optimal solution of the coil cutting problem.1

KEYWORDS

Genetic Algorithm; Coil Cutting; Cutting Optimization;

INTRODUCTION

For a processing enterprise, it is important to use a reasonable use raw materials in order to reduce costs and improve efficiency1.For example, in the manufacturing process of capacitor, for is, the cathode foil and electrolytic paper and other raw

materials cannot be used directly, enterprises generally buy the coil, and then according to the different distribution of the specifications of the capacitor for cutting. For the minimum amount of waste generated during the cutting process, the remaining number of rolls that have been cut are the least to find the optimal cutting distribution scheme which can meet the demand. In recent years, a large number of intelligent algorithms have emerged, such as genetic algorithm, tabu search algorithm, ant colony algorithm, immune algorithm, particle swarm algorithm, simulated annealing algorithm23, etc., all can be tried to cut the optimization. Genetic algorithm is similar to natural evolution, according to the genes on the chromosome to find a good chromosome to solve the problem. The algorithm itself does not understand the problem to be solved. It only evaluates each chromosome generated in the algorithm, and then chooses the chromosome based on the fitness value, so that the chromosomes with high adaptability get more breeding opportunities . It can be seen that the genetic algorithm is a kind of computer simulation method, which has the characteristics of wide application, multi-point search, good robustness, strong adaptability and high parallelism. In essence, it is a kind of adaptive ability to search the optimization method8.

In this paper, we mainly analyze the genetic algorithm and improve it in the application of the optimization problem of coil cutting, and improve the optimization ability of the intelligent algorithm9 -11. According to the experimental analysis, compared with the traditional genetic algorithm, the improved genetic algorithm has better adaptability and stability, and better search ability.

PROBLEM DESCRIPTION AND MODEL ANALYSIS

Different specifications of aluminum foil and electrolytic paper generally width and width are different, even if the specifications of raw materials are consistent, the general length and width of the production of different manufacturers are different. The material of the material is usually cut to match order. For different orders of its product specifications and the number of orders, there will be cutting width and cutting the number of differences. In general, the calculation of the width of each coil and the number of cookies that are assigned to each one is a lot of manpower, and there are often waste products. Based on this, the problem to be solved is to let the system optimize the volume of the known coil, the width of the cutting and the corresponding number of cookies as the input parameters, and optimize the algorithm to reduce the waste generation and the remaining cutting count to obtain the optimal cutting plan.

Parameter Definition And Description

less than the maximum width of the cutting type of the number of volumes; m3: the remaining width need to re-cut the number of volumes. i: volume number; qi: roll width; wi: residual width; vi: obsolete width; yi: remaining available width; ui: residual width after cutting width.

Model Design

Planning objectives:

Goal 1: Under the condition that the given π corresponds to the required number of bakes, find the coil cutting scheme that satisfies the condition and has the smallest total waste width. The waste width penalty factor is denoted by k1.

Goal 2: In the remaining width, try to make the remaining width equal to one of the width values of one of the cutting types or the multiple of several width values. Otherwise, cut the remaining waste width penalty factor again with k2.

Goal 3: When a coil opened, try to cut it as soon as possible. The penalty factor with a residual width of zero is denoted by k3.

Goal 4: When a coil is opened, try to make the remaining width of the coil after opening is less than the maximum width of the cutting type, in order to avoid each coil are not fully utilized, otherwise regarded as indiscriminate closure, the penalty factor with k4 said.

Goal 5: In the remaining width, try to make the remaining width equal to the cutting of a certain kind of width value, to avoid the remaining waste width. Otherwise the next must be cut again, once again cut the penalty factor with k5 said.

The total objective function C is expressed by the formula (1):

C min ∗ ∗ ∗ m ∗ m ∗ m (1)

The above k1, k2, k3, k4, k5 are constants and the constraint conditions are:1 the total number width of the initial given must be greater than the product of the target width set and the number of the pie. 2 The cutting width must be less than the width of the roll. 3 When cutting, arrange the serial number in front of the coil.

ALGORITHM DESIGN AND SOLUTION

Coding Method Design

Parameter matrix12 and description:

∗

⋯

⋮ ⋱ ⋮

⋯

(2)

Among them, aij represents the number of rolls that are required to cut the width of the j. From the above, the jth cake width of the material to be cut the total number of sj is as follows:

⋯ (3)

After the whole volume of the coil is cut, the remaining width wi is:

w q a ∗ g a ∗ g ⋯ a ∗ g (4)

When w min g |j ∈ N , the discard width is the remaining width

v w

y 0 (5)

When w min g |j ∈ N ,the remaining available width is the remaining width

v 0

y w (6)

The chromosome coding method can be determined according to the coding matrix A described above. The definition of chromosomes consists of m pieces, each of which contains n genes, each of which is determined by a row of coding matrices, separated by "-1" between small segments and small segments, representing different volumes of the entire coil. So the length of the chromosome is m * n + m-1. The chromosome can be expressed as:

, ⋯ , , 1, , ⋯ , , 1, ⋯ , 1, , ⋯ , (7)

Design of Fitness Function

Because it is the minimum value, the fitness function is set to the reciprocal of the sum of the discarded widths of the coils. The objective function of the r chromosome is denoted by C r, k is a constant, and the fitness function can be expressed as:

F

Population Initialization

The initial population was generated using the stochastic generation method. According to the coding matrix, randomly generate a chromosome, calculate whether the chromosome satisfies the constraints, if satisfied, then the initial population, if not satisfied, it will be abandoned. The process is repeated until the number of individuals in the initial population reaches a pre-set value.

Choose Design

Using the fitness ratio method to determine the selection probability, the probability of each individual being selected is proportional to the fitness function value. Assumed group size for R, the r individual fitness value of F r, then the probability of this individual being chosen is

p F

∑ F (9)

Use the tournament selection method13 to select the individual. From the group randomly selected k individuals (k called the scale of the competition), the most adaptive individuals to save as a male parent. Repeated selection, so that the number of selected male parents to reach the number of population size to complete the selection operation.

Cross Design

Using a uniform method, each time in accordance with the uniform probability of each segment of each segment of the same cross-swap, the formation of two new individuals. The probability that each bit is selected is random and equal and independent of the other bits.

Assuming the following two chromosomes:

: 7,5,5,9, 1,8,9,4,13, 1,12,2,3,11, 1,6,3,15,4, 1,2,9,6,10

: 6,6,3,6, 1,10,8,5,15, 1,13,3,5,9, 1,5,0,10,2, 1,3,12,10,15

If the extraction cross position is 2, then the two new chromosomes are obtained as follows:

: 7,6,5,9, 1,8,8,4,13, 1,12,3,3,11, 1,6,0,15,4, 1,2,12,6,10

After the cross operation, to check whether the new individual legitimacy, abandon the illegal individual, leaving the legitimate individual as a new generation.

Variation Design

Using the cycle of mobile mutation, the first random selection of a gene bit, and then in order to extract the order of each section of the gene composition of the ring, to the left after the cycle of a place back to the original locus.

Assuming that the randomly selected gene bit is 3, the mutation process is as follows:

the variation before:

: 7,6,5,9, 1,8,8,4,13, 1,12,3,3,11, 1,6,0,15,4, 1,2,12,6,10

the variation after:σ :7,6,6,9, 1,8,8,5,13, 1,12,3,4,11, 1,6,0,3,4, 1,2,12,15,10

Mutations may produce illegal chromosomes, so after the mutation operation to verify its legitimacy, the illegal individual to give up, to retain the legitimate individual as a new generation into the population.

Improved Design Based on Preference Algorithm

The result of the traditional genetic algorithm is that the residual width is just the same as the cutting width, which leads to some breadth of the final number of crop cakes greater than the expected number of biscuits. This result is not ideal. Based on this, this paper designs a preference-based gene adjustment program. In each planning result, each chromosome is evaluated to see if there is a case where the remaining width is equal to the cutting width. If it appears, search for the current volume from the coil with the largest remaining width to the coil with the smaller remaining width If the number of the corresponding cutting width of the cake is greater than 1, such as greater than 1 the current volume of the corresponding cutting width of the number of breadcounts minus 1, the remaining width and cutting width of the same volume of the corresponding cutting width of the cake plus 1.

Improve the adjustment process as follows:

Assume that a chromosome before adjustment is :

: 8 2 0 2 0 1 1 5 1 1 0 0 2 1 0 3 0 1 0 1 1 5 2 1 2 0 2 1 1 1 2 0 1 1 1 0 1 0 2 4 0 1 0 1 0 1 0 0

After adjustment for chromosomes :

The corresponding residual width before and after adjustment of chromosome is shown in figure 1 (a) (b).

(a)

[image:7.612.167.447.139.455.2](b)

Figure 1. Remaining width distribution before(a) and after(b) adjustment.

1 2 3 4 5 6 7

Cut width 106 80 53 114 65 94 21

Residual width 12 0 0 0 0 8 189

0 50 100 150 200 250

volume

w

ide

1 2 3 4 5 6 7

Cut width 106 80 53 114 65 102 13

Residual width 12 0 0 0 0 0 197

0 50 100 150 200 250

volume

w

Figure 2. Algorithm to improve the strategy.

The algorithm to improve the strategy is shown in Figure 2.

SIMULATION TEST AND RESULT ANALAYSIS

Simulation Example Model Construction

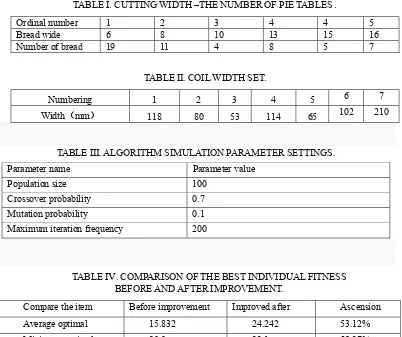

The relevant input parameters for modeling are shown in Table 1 and Table 2.

Simulation Parameter Settings

The simulation parameter Settings are shown in table 3

Simulation Test and Result Analysis

The best chromosomes obtained by traditional genetic algorithms:

[5 3 1 3 1 0 -1 6 3 2 0 0 0 -1 1 1 0 3 0 0 -1 5 2 0 0 1 3 -1 1 2 0 1 2 0 -1 0 0 0 0 0 2 -1 1 0 1 1 1 2]

The best chromosomes obtained by improved genetic algorithm:

The optimal individual fitness before and after improvement is shown in table 4.

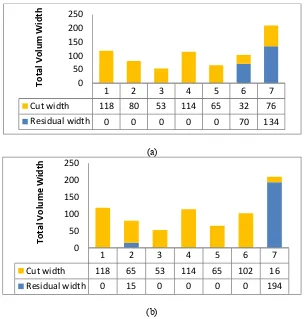

[image:9.612.101.503.169.506.2]The remaining width distribution of the pre - and post roll is improved, as shown in Figure 3 (a) (b).

TABLE Ⅰ. CUTTING WIDTH –THE NUMBER OF PIE TABLES .

Ordinal number 1 2 3 4 4 5

Bread wide 6 8 10 13 15 16

Number of bread 19 11 4 8 5 7

TABLE Ⅱ. COIL WIDTH SET.

Numbering 1 2 3 4 5 6 7

Width(mm) 118 80 53 114 65 102 210

TABLE Ⅲ. ALGORITHM SIMULATION PARAMETER SETTINGS. Parameter name Parameter value

Population size 100

Crossover probability 0.7 Mutation probability 0.1 Maximum iteration frequency 200

TABLE Ⅳ. COMPARISON OF THE BEST INDIVIDUAL FITNESS BEFORE AND AFTER IMPROVEMENT.

Compare the item Before improvement Improved after Ascension

Average optimal 15.832 24.242 53.12%

(a)

[image:10.612.145.450.82.401.2](b)

Figure 3. Before(a) and after(b) the improvement of the remaining width of the roll.

The results show that the residual width is mainly distributed on the latter two rolls. After the improvement, only the second coil remains 15mm, which belongs to the usable width, which can be directly used next time. The actual width of the roll is zero, and all the remaining widths are concentrated in the last one, which results in the expected planning optimization. The best chromosomal fitness and average fitness evolution trends of the two algorithms are shown in Fig. 4 and Fig. 5 respectively

1 2 3 4 5 6 7

Cut width 118 80 53 114 65 32 76

Residual width 0 0 0 0 0 70 134

0 50 100 150 200 250

Total Volum

Width

1 2 3 4 5 6 7

Cut width 118 65 53 114 65 102 16

Residual width 0 15 0 0 0 0 194

0 50 100 150 200 250

Total Volume

W

Figure 4. Evolutionary trends in the optimal individual fitness values before and after improvement.

Figure 5. Evolutionary trend of average fitness before and after improvement.

Figure 6. Comparison of optimal fitness values by one hundred.

For 100 consecutive results, the stability is shown in figure 6.

Analysis of the above data shows that the results of example simulation in this paper based on the idea of preferences to the condenser coil cutting program planning problem of solution can meet the practical requirements for the management of cutting coil. In terms of performance, the deviation of the first 100

15 25 35

1 24 47 70 93

11 6 13 9 16 2 18 5 Fitness percentage Number of iterations before and after the improvment of fitness evolution trend Improved after Before improvement 0 5 10 15 20 25

1 24 47 70 93

11 6 13 9 16 2 18 5 Fitness percentage Number of iterations Improved after Before improvement 15 25 35 45

1 12 23 34 45 56 67 78 89

[image:11.612.177.443.436.552.2]calculation results is not significant, and the fitness is basically stable at about 33%, indicating the stability of the algorithm is good.

CONCLUSIONS

This paper mainly studies the optimization of coil cutting in the process of capacitor manufacturing. First of all, through the coil cutting leads to cutting optimization problem, define and explain the cutting model to be used parameters. Then the mathematic model is established for the optimization problem of coil cutting, and the model is solved by improving the genetic algorithm. Finally, the feasibility of the algorithm is verified by programming simulation, and the simulation results are analyzed statistically.

ACKNOWLEDGMENT

This work is supported partly by Project “Automobile Precision Stamping Complex Parts Intelligent Detection System”, Foundation of Guangdong Province Science and Technology under Grant No.2015. A030401088, Special and Technology Enterprises of Provincial Science and Technology Enterprises of Small and Medium sized, “Multi-params Precision Intelligent Detection System of Automoblie Engine Pistion Ring”, under Grant No.2016A010119143, Project “The Automoblie Complex Precision Fine Blanking Parks Robot Intelligent Detection System”, Foundation of Guangdong Province Science and Technology under Grant of No.201604010011.

REFERENCES

1. U. Leeton and T. Kulworawanichpong, "Application of key cutting algorithm to optimal power flow problems," The 8th Electrical Engineering/ Electronics, Computer, Telecommunications and Information Technology (ECTI) Association of Thailand - Conference 2011, Khon Kaen, 2011, pp. 897-900. doi: 10.1109/ECTICON.2011.5947985.

2. L. You-peng, Z. Bo-hao and C. Fan, "Application of multi population genetic algorithm in traffic assignment problem," 2017 IEEE 2nd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 2017, pp. 1889-1893. doi:

10.1109/IAEAC.2017.8054341.

3. S.Y. Kuo and Y.H. Chou, "Entanglement-Enhanced Quantum-Inspired Tabu Search Algorithm for Function Optimization," in IEEE Access, vol. 5, pp. 13236-13252, 2017. doi:

10.1109/ACCESS.2017.2723538.

4. Z. Yang, Y. Yu, K. Zhang, H. Kuang and W. Wang, "An improved ant colony algorithm for MapReduce-based fleet assignment problem," 2017 IEEE 2nd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China,

5. X. Kang, K. Li and W. Zhu, "A new localization method for mobile robots using Genetic Simulated Annealing Monte Carlo Localization," 2011 IEEE International Conference on Mechatronics and Automation, Beijing, 2011, pp. 1780-1785.doi:10.1109/ICMA.

2011.5986249.

6. J. Li, L. Yang, J. Liu, D. Yang and C. Zhang, "Vector evaluated adaptive immune particle swarm optimization algorithm for multi-objective reactive power optimization," 2010 International Conference on Power System Technology, Hangzhou, 2010, pp. 1-5. doi:

10.1109/POWERCON.2010.5666529.

7. H.M. Yatim, I.Z.M. Darus and M. S. Hadi, "Modeling of flexible manipulator structure using particle swarm optimization with Explorer," 2014 IEEE Symposium on Industrial Electronics & Applications (ISIEA), Kota Kinabalu, Malaysia, 2014, pp. 113-118. doi:

10.1109/ISIEA.2014.8049882.

8. N. Weerayuth and N. Chaiyaratana, "Closed-loop time-optimal path planning using a multi-objective diversity control oriented genetic algorithm," IEEE International Conference on Systems, Man and Cybernetics, 2002, pp. 7 pp. vol.6-.doi: 10.1109/ICSMC.2002.1175611.

9. Durak and D.T. Aksu, "A genetic algorithm based solution for the online cutting problem with defects," 2015 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 2015, pp. 1805-1809.doi: 10.1109/IEEM.2015.7385959.

10. M. Alhomidi and M. Reed, "Finding the minimum cut set in attack graphs using genetic algorithms," 2013 International Conference on Computer Applications Technology (ICCAT),

Sousse, 2013, pp. 1-6.doi: 10.1109/ICCAT.2013.6522000.

11. M. Tang and S. Pan, "A hybrid genetic algorithm for the minimum interconnection cut problem," 2013 IEEE Congress on Evolutionary Computation, Cancun, 2013, pp.

3004-3011.doi: 10.1109/CEC.2013.6557935.

12. Z. Wu, H. Cao and D. Li, "An Approach of Steganography in G.729 Bitstream Based on Matrix Coding and Interleaving," in Chinese Journal of Electronics, vol. 24, no. 1, pp.

157-165, 01 2015. doi: 10.1049/cje.2015.01.026.

13. Andrzej and K. Stanislaw, "A new constraint tournament selection method for multicriteria optimization using genetic algorithm," Proceedings of the 2000 Congress on Evolutionary Computation. CEC00 (Cat. No.00TH8512), La Jolla, CA, 2000, pp. 501-508 vol.1.doi: