Volume 8, Issue 6, June 2019, ISSN: 2278 -7798

IR Controlled Automatic Whiteboard Cleaner

Using Arduino

Nay Yee Win War, Zaw Myo Tun

Abstract- This whiteboard cleaner is the machine that can cleanautomatically the desired part of whiteboard by using IR remote. The machine can support to perform the work easier and to make the user more comfortable. Whiteboard is large in size so it takes time for cleaning the whiteboard manually. The main goal of this paper is to clean the whiteboard by using IR control. Stepper motors are used to move x and y direction of the whiteboard. Servo motors are applied to press and release the duster. CNC shield and A4988 driver are used to control the bipolar stepper motor. IR remote is used to control the cleaning process. In this machine, the user can choose for cleaning the whiteboard with various instructions. Firstly, the machine can clean left side, right side and the whole area of the whiteboard. Secondly, that machine can also clean the desired parts of the whiteboard. Automatic white board cleaner makes human work easier and also reduces the use of human power.

Keywords –Arduino uno, CNC shield, Stepper motor, Servo

motor, IR remote.

I. INTRODUCTION

Education is the back bone of a nation. Education comprises of teaching and learning. The resources materials used in teaching becoming updated along with the teaching and learning techniques. Writing was earlier done on sand, walls, slates made out of wood, chalkboards and in recent times on white boards and electronic boards. Chalk dust scatter causes serious health problems. Because of these reasons whiteboard has been widely implemented into many other sectors of human endeavour besides teaching [1]. Sometimes the number of teachers is not enough and fix schedule in one day that will cause teachers to teach four or five times a day. This may lead to fatigue in teacher. When the next class session is start teachers will complain when the board is not cleaned. Another problem is mysterious loss of duster. [2].Automatic cleaning machine can solve above problems. This system can be saved the wasting time and human effort. The teacher can erase easily by using remote control in the classroom. This cleaner is made for erasing many part of the whiteboard. First part is Left side, second part is right side and third is all area of the whiteboard. When the teacher is writing on the right side, the cleaner can work for erasing the left side after the students are finished in copying. And then teacher is finished in writing right side, the cleaner can erase right side. If he wants to clean all area, he can press for cleaning all. Another part is dividing the whiteboard by eight parts for cleaning. The user will be satisfied for using this kind of whiteboard cleaning machine.

II. LITERATUREREVIEW

S.Joshibaamali And K.Geetha Priya has explained that the machine can operate in three selectable operatable modes. In the first mode, it cleans the left side of the board. In the second mode it cleans the right side of the board. In the third mode it cleans the whole area of the board. The machine uses two

stepper motors to move duster in horizontal (x-axis) and vertical (y-axis) direction to cover the whole area. To move the duster in up and down direction linear motor is used. Infrared transceiver is used to detect X- axis motor movement. Four limit switches are used to detect the boundary of the whiteboard. A dsPIC30F401 microcontroller which was programmed in C language is used as the main controller in the machine.[1]

Sonia Akhter, Anindo Saha ,Md.Rayhan Parvez koushik, Md. Asaduzzaman, Razoana Islam Shorna, Md.Moudud Ahmed explained that when the teacher switch on the supply, current is passed to the 18V adapter and then it passes through Arduino. To sense the distance and time specified by ARDUINO , a sonar sensor is used, hence the motor rotates in both clock-wise & anti-clockwise direction [2].

Dhananjay N. Jadhav, Aditi H. Manajan , Mayuri B. Surve & Pramod R. Sonawane explained that to implement this approach we have used Arduino UNO as a controller to control the motor operation during the whole process. We have used IR receiver to move duster and curtains in reverse and forward direction. A motor driver is used to supply 12v power supply to run the motor when it receives high at input through the remote button press. When any button is pressed by the user from remote it transmits a unique decimal value for that particulate button which is then received by IR sensor TSOP1738 connected to an Arduino[3].

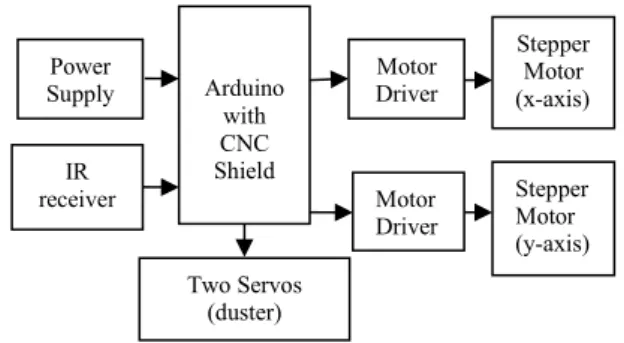

III. BLOCKDIAGRAM OF THESYSTEM

The functional block diagram of overall system is shown as below.

Fig. 1 Block diagram of Automatic Whiteboard Cleaner When the user switch on the supply, current is passed to the 12V adapter and then it passes through Arduino Uno. IR sensor is connected to Arduino to receive the input serial data from the user. When the user is pressed the button on the remote, it transmits a unique decimal value to the IR sensor. CNC shield can be plugged on top of the Arduino and making more flexible to use. A4988 is used to drive the stepper motor. Motors can go forward and reverse direction by the control of the arduino. CNC shield and A4988 driver is used for over-current and over-temperature protection. Stepper motor has a good precision than the other motor. Two Steppers is used for

Power Supply Arduino with CNC Shield Motor Driver Stepper Motor (x-axis) Two Servos (duster) IR receiver Motor Driver Stepper Motor (y-axis)

Volume 8, Issue 6, June 2019, ISSN: 2278 -7798 moving the duster in X-axis and Y-axis direction. For

balancing the duster, servo motor can press the duster. In this paper, the system can work with various instructions. Automatic whiteboard cleaner can clean left side, right side, all area and eight parts of the whiteboard. The user can easily choose for cleaning the desired area.

III. HARDWARECOMPONENTS A. Arduino Uno Microtroller

Arduino Uno is a microcontroller board based on the

ATmega328P. It has 14 digital input/output pins(of which 6 can be used as PWM outputs), 6 analogue inputs, a 16MHz quartz crystal, a USB connection, a power jack, an ICSP header and a reset button. It contains everything needed to support the microcontroller; simply connect it to a computer with a USB cable or power it with a AC-to-DC adapter or battery to get started [4].

Fig. 2 Arduino UNO B. Stepper motor

A stepper motor is a brushless DC electric motor that divides a full rotation into a number of equal steps. The motor's position can then be commanded to move and hold at one of these steps without any position sensor for feedback (an open-loop controller). A stepper motor is the resonance effect often exhibited at low speeds and decreasing torque with increasing speed [5].

This machine uses two stepper motors to move the duster in horizontal (X-axis) and vertical (Y-axis) direction.

Fig .3. Stepper Motor Table. I Microstepping Resolution Truth Table

MS

1 MS2 MS3 ResolutionMicrostep ExcitationMode

L L L Full Step 2 Phase

H L L Half Step 1-2 Phase

L H L Quarter Step W1-2Phase

H H L Eighth Step 2W1-2Phase

H H H Sixteenth Step 4W1-2Phase

In this method, both windings of the motor are always energized. Instead of making one winding off and another on, in sequence, only the polarity of one winding at a time is changed as shown:

Winding A: + - - + + … Winding B: + + - - + … C. A4988 driver

Simple step and direction control interface. Stepper motor driver lets for control one bipolar stepper motor at up to 2A output current per coil. It operates from 8V to 35V and can deliver up to approximately 1A per phase without a heat sink. Motor driver features are adjustable current limiting, over-current and over-temperature protection, and five different microstep resolutions (down to 1/16-step)[6].

Fig. 4 A4988 Driver D.CNC shield

This CNC shield is designed to control a CNC or a 3D printer. It comes with 4 sockets A4988 stepper driver. This board has Arduino pin connections and pins for engine and other peripherals. Shield allows external power supply up to 36V for powering powerful motors [7].

Fig. 5 CNC Shield E. Servo motor

A servomotor is a rotary actuator or linear actuator that allows for precise control of angular or linear position, velocity and acceleration. It consists of a suitable motor coupled to a sensor for position feedback.

Fig. 6 Servo motor

It also requires a relatively sophisticated controller, often a dedicated module designed specifically for use with servomotors. Servomotors are not a specific class of motor although the term servomotor is often used to refer to a motor

Volume 8, Issue 6, June 2019, ISSN: 2278 -7798 suitable for use in a closed-loop control system. In this system,

servo is used to press the duster [8]. E. IR Sensor TsoP738

IR sensor component made up of a pin diode and a pre amplifier which are merging into a single device. Generally the output of sensor is active low and it provides +5V in off state. When IR remote generates a signal at the frequencyof38kHz, its output goes low.

Fig. 7 IR remote

This mini slim infrared remote is control with 20 function keys. Its transmit distances up to 5 meters [9].

IV. HARDWAREIMPLEMENTATION

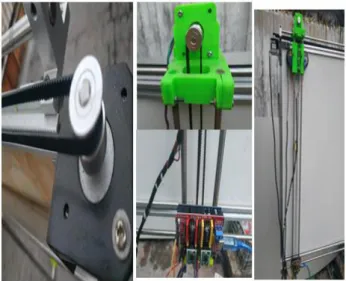

Firstly, the dimensions are considered, cut the whiteboard and aluminium frame. The required components are ordered and set up for moving the duster. Linear rod, linear ball baring, timing belt and printer parts are set up with suitable place by using the nut, washer and bolt. The diameters of the whiteboard were 3 feet long and 2 feet 5 inches wide. The user can choose the size of the whiteboard as needed and easily step up with this component.

Fig. 8 Experimental Setup

Secondly, the two solid rods are used to be stable for moving machine. After that, two stepper motors are fixed with the axis pulleys and holders by using screws and nuts. Timing belt is connected with pulleys to rotate the motors.. This type of cleaner moves vertically by means of motor mechanism and clean the whiteboard with the help of duster attached to it but it could not support sufficient pressure on the whiteboard. Two servo motors are set up besides the stand for balancing the duster. For getting the smooth and fast rotation, the timing belt

can operate. This type of machine is tested with various designs. Finally, the hardware implementation of automatic whiteboard cleaner machine is completed.

Fig. 9 Constructed whiteboard cleaner V. WORKINGPROCEDURE

The system flow chart is shown in Figure which represents the sequenced processes and steps taken to carry out specific action with the application.

Fig. 10 System flow chart Start

Initialize the system

If data=L Yes No End Read data Yes Run motors to clean left side

No

If data=R Run motors to

clean right side

If data=all Run motors toclean all area

If data= select part Run motors to clean selected part Yes No

Stop cleaning process No

Volume 8, Issue 6, June 2019, ISSN: 2278 -7798 When the system is start, all components are ready to use.

Arduino uno is waiting code number from IR remote. When it produces code to arduino uno, the motor is started working as the instruction.

Fig. 11 Schematic Diagram of cleaning machine

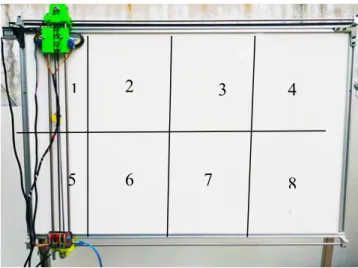

Fig. 12 Program flow chart of motor control system for cleaning process Firstly, machine can clean the whole area of the whiteboard. When the user is switch on all clean switch, the system will work for cleaning all area of the whiteboard. Secondly, the machine can clean left side. When the user chooses to clean left side, the machine will clean that side. Thirdly, the machine can also goes for cleaning right side. In fourth, the area of the whiteboard is divided into eight parts. Each part can clean exactly with the help of the motor driver and motors. Otherwise, the user can separate the parts as needed.

VI. EXPERIMENTALTEST ANDRESULT

Testing with the IR receiver and remote is shown in figure. IR sensor has signal pins, ground pin and supply pin. Signal pin of the sensor is connected with the 11 pin or z+ pin in board.

Fig. 13 Test with IR remote

When the user presses the keyword from the remote, the receiver gets data for working. The data can drive the motor by making high or low to motor driver pins. If the code is not match, motor driver pins will be low.

Fig. 14 Test result to know the serial data from remote Servos release

Stepper (x-axis) goes to Initial If cleaning area is finished?

Yes Stepper (y-axis) goes down and up

Servos press Stepper (x-axis) goes to the

selected part If arrived? Yes No Yes If cleaning data is received? No

Read cleaning Data Start Initialize the system

Volume 8, Issue 6, June 2019, ISSN: 2278 -7798 Fig. 11 shows a serial monitor output window form for

cleaning number five block. This machine tends to clean the selected area without using any vision. That kind of way is easy for cleaning the whiteboard. When the teacher or student wants to clean the part of the whiteboard, they can clean easily it by using remote.

Fig. 12 Separated eight parts

In this paper, the cleaning process can work for eight parts. Otherwise, the user can divide the part of the whiteboard more than eight parts. This cleaning duster is smaller than other project because the user can erase the small part of the whiteboard.

Table. II Time for cleaning the required area

Cleaning Area Time for complete All area 1min 55 sec

Left side 1min

Right side 1min 4sec

1 13sec 2 16sec 3 19sec 4 21sec 5 19sec 6 23sec 7 26sec 8 29sec

Time for cleaning process is one of the important facts that must be considered. When the machine takes too long time, it will make the user boring to wait that. This machine takes a few times to cleaning the desired parts. By using this machine, the user can save every second and human effort

. VII. CONCLUSION

This system can work automatically for cleaning process. This machine can clean left side, right side and the whole area of the whiteboard with suitable time. And the machine also made to clean the desired parts of the whiteboard with the help of stepper motor by using IR remote. Automatic Whiteboard Cleaner Machine is an alternative machine that can help

teacher and student to clean a whiteboard by working faster and smoothly with suitable time.

ACKNOWLEDGMENT

F.A.Author thanks to U Zaw Myo Tun, Associate Professor, Department of Electronic and Communication Engineering for kind permission to prepare for this paper, for his close supervision, helpful advice, encouragement and numerous invaluable guidance. The author would also thank to all teachers and friends who willingly helped the author throughout the preparation of the paper.

REFERENCES

[1] Sonia Akhter, Anindo Saha ,Md.Rayhan Parvez koushik, Md. Asaduzzaman, Razoana Islam Shorna, Md.Moudud Ahmed “Automatic Whiteboard Cleaner Using Microcontroller Based Rack and Pinion Mechanism” International Conference on Mechanical, Industrial and Materials Engineering 2015(ICMIMME2015) 11-13 December,2015,RUET, Rajshahi ,Bangladesh

[2] S.Joshibaamali And K.Geetha Priya,’ Automatic Duster Machine’, International Journal Of Emerging Technology In Computer Science & Electronics (IJETCSE) ISSN: 0976-1353 Volume 13 Issue 1 –March 2015

[3] Dhananjay N. Jadhav, Aditi H. Manajan , Mayuri B. Surve & Pramod R. Sonawane “ Automatic Board Cleaning and Curtains Operation” Imperial Journal of Interdisciplinary Research(IJIR) vol-3,Issue-4, 2017,ISSN: 2454-1362, http://www.onlinejournal.in [4] https://store.arduino.cc/usa/arduino-uno-rev3 [5] http://osoyoo.com/2017/04/07/arduino-uno-cnc-shield-v3-0-a4988/ [6] https://en.wikipedia.org/wiki/Stepper_motor [7] https://www.robotshop.com/.../datasheet-... [8] https://www.elprocus.com/servo-motor/ [9] https://www.makerlab-electronics.com/product/arduino-ir-remote-control-kit/