Strojniški vestnik - Journal of Mechanical Engineering 53(2007)10, 683-695 UDK - UDC 621.436

Izvirni znanstveni članek - Original scientific paper (1.01)

Vpliv biodizla na zgorevanje in emisijske značilke dizelskih

motorjev

The Influence of Biodiesel on the Combustion and Emission Characteristics of a

Diesel Engine

Aleš Hribernik - Breda Kegl (Fakulteta za strojništvo, Maribor)

Rezultati raziskav vpliva biodizla in njegovih mešanic z gorivom D2 na delovanje dizelskih motorjev so si pogosto nasprotujoči. Medtem ko velja glede emisij splošna ugotovitev o zmanjšanju koncentracije saj ter zvečanju NOx, pa so si ugotovitve o emisijah nezgorelih oglikovodikov in CO pogosto nasprotujoče. Tudi poročanje o zmanjšanju emisij NOx ni redko. Vzrok za tako različne ugotovitve tiči najverjetneje v različnih razmerah raziskovanja, motorjih z različno obliko zgorevalnega prostora, različnih sistemih za vbrizg goriva in podobno. Da bi analizirali mogoče vplive, smo opravili raziskave na dveh različnih dizelskih motorjih. Izmerili smo obratovalne in emisijske značilke p ri delovanju z biodizlom in gorivom D2 ter posneli indikatorske diagrame, s katerimi smo lahko analizirali potek zgorevanja. Rezultati so pokazali, da ugotovitev o vplivu biodizla na p otek zgorevanja in emisijske značilke ne smemo posploševati, saj se za oba obravnavana m otorja pom em bno razlikujejo.

© 2007 Strojniški vestnik. Vse pravice pridržane.

(K ljučne besede: bio-goriva, zgorevanje, dizelski motorji)

The results o f investigations o f the influence o f biodiesel fu e l and its blends with D2 fu e l on the operation o f diesel engines are often contradictory. Although there is a common b elief that the use o f biodiesel reduces soot and increases NOx emissions, the findings fo r CO and H C emissions tend to vary fro m case to case. Furthermore, there are even some reports o f NOx reduction when using biodiesel. These inconsistent conclusions are caused by the non-uniformity o f engine testing. These tests were perform ed on different engines using different combustion-chamber geometries, different fuel-injection systems, etc. In order to identify and analyze some o f the possible reasons we tested two different diesel engines. The operation and emission characteristics o f both engines with biodiesel and D2 fu e l were measured and compared, and in-cylinder pressure traces were acquired and used fo r the combustion analyses. The results obtained fo r both engines showed that findings regarding the influence o f biodiesel fu e l on the combustion process and emission form ation could not be generalised, and had to be interpreted as being specific to the particular engine.

© 2007 Journal o f M echanical Engineering. All rights reserved. (Keywords: bio-fuels, combustion, diesel engine)

0 UVOD

V sk lad u s sm ern icam i EU naj bi se v prom etnem sektorju uporaba biogoriv do leta 2020 zvečala na kar 20 % celotne porabe goriv za pogon m otornih vozil. K tem u spodbujajo tako okoljski vidiki (zmanjševanje emisij toplogrednih plinov), kakor tudi doseganje večje energetske neodvisnosti članic EU. Doseganje tako visokih ciljev je mogoče z uporabo čistih biogoriv ali njihovih mešanic s običajnim i fosilnimi gorivi. Pri tem je za pogon

0 INTRODUCTION

bio-m o to rn ih v o z il z b e n c in s k im i m o to rji n ajprim ernejši etanol, za dizelske m otorje pa biodizel. Slednji se uporablja že sedaj. Največkrat s 5-odstotnim prostominskim deležem v mešanici z gorivom D2.

Z n ačilke b io d iz la , k i j i h p rid o b im o iz rastlinskih olj in odpadnih živalskih maščob s postopkom transestrifikacije se pomembneje ne razlikujejo od značilk goriva D 2 , zato ga lahko b rez v e č jih posegov u p o ra b im o v d iz e ls k ih motorjih. Zaradi njegove nižje kurilnosti se sicer zmanjšata moč in navor motorja, vendar pa lahko n je g o v a sestava p o m e m b n o p ris p e v a k zmanjšanju emisij. Biodizel.vsebuje dobrih 10 % k is ik a , zato lahko igra podobno vlogo kako r dodatki gorivu v obliki oksigentov, k i uspešno z a v ira jo nastanek saj ( [ 1 ] in [ 2 ] ) . D o d a tn o prednost p ri zm anjševanju em isije delčkov, še posebej tistega dela, k i izv ira iz sulfatov, daje biodizlu majhen delež žvepla ([3 ] in [4 ]). D elež k is ik a v b io d iz lu v p liv a tu d i na zm anjšanje koncentracije C O in nezgorelih o gljikovodikov ( H C ) [5 ] , v e n d a r pa k re p ite v o k s id a c ijs k ih

pojavov pospeši nastajanje dušikovih oksidov N O x in p o v e č a n je n jih o v e k o n c e n tra c ije v izpušnih plinih. Sprememb emisijskih značilk ob uporabi biodizla pa ne smemo posploševati, saj n a n je p o m e m b n o v p liv a jo tu d i o b lik a zgorevalnega prostora, postopek vb rizg avan ja goriva in obrem enitev m otorja. Tako nekateri avtorji poročajo o znatnem zvečanju emisij N O x in zmanjšanju emisij H C ter C O ([5 ] in [6 ]), spet drugi opažajo le zmerno zvečanje N O x ob skoraj nespremenjenih emisijah H C in C O ([3 ] in [7 ]), tretji pa zasledijo celo zmanjšanje vseh emisij ([8 ] in [9 ]). Razlaga za tako neenotne rezultate raziskav se skriva v dejstvu, da so bile razmere, pri katerih so bile raziskave opravljene, pogosto precej različne.

D a bi u g o to v ili, kolikšen je lahko v p liv ra zlič n ih razm er pri raziskovanju na izm erjene e m is ijs k e značilke m o to rja p ri d e lo v a n ju z b io d iz lo m , sm o m e r itv e iz v e d l i n a d v e h ra zlič n ih d izelskih m o to rjih T A M B F 4 L 5 1 5 C

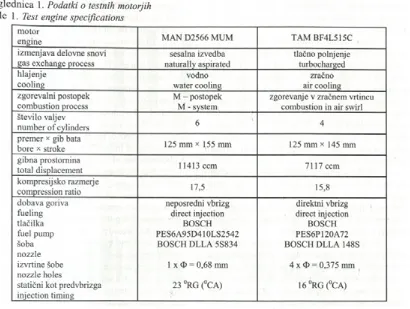

in M A N D 2 5 6 6 M U M . Osnovne specifikacije obeh m o to rje v so p odane v p r e g le d n ic i 1. Izb ran a m otorja se v osnovnih g eom etrijskih iz m e ra h s k o ra j ne r a z lik u je t a , p o m e m b n e ra z lik e pa so v postopku zg o revan ja, načinu izm e n ja v e delovne snovi in iz v e d b i h la je n ja m otorja.

fuels or by the application o f their blends with standard fuels. Ethanol is already used as a substitute for gasoline in gasoline engines and 5 % biodiesel blends with D 2 fuel are used in diesel engines.

A process called transesterification is used for the production o f biodiesel, the characteristics o f which are very similar to those o f D 2 fuel. No special engine modifications are, therefore, necessary when D 2 fuel is replaced by biodiesel. Although there is a reduction o f the engine’s torque and power due to the lower calorific value o f biodiesel, its chemical composition may significantly effect the reduction o f emissions. Biodiesel contains more than 10 wt% oxygen and the addition o f oxygen-containing hydrocarbons to diesel fuel has been shown to have significant potential for reducing particulate emissions ([1] and [2]). The low sulphur content o f biodiesel reduces particulate emissions too, particularly the particulates associated with sulphates [3]. Also, a sulphur-sensitive exhaust-gas aftertreatment may be used to reduce other emissions from the exhaust gas [4], The oxygen content may influence the reduction o f CO and H C emissions [5], too. However, enhanced combustion performances may intensify the combustion and accelerate N O x formation, thus increasing its emissions. An extensive literature review proved that the findings on the

influence o f biodiesel on engine combustion and emissions cannot be generalized. Combustion-chamber geometry, the fuel-injection process, combustible mixture formation w ith pre-ignition and ignition

processes, and engine load may significantly influence the combustion and the formation o f emissions. Some authors ([5] and 6]) report very high increases o f N O x

emissions, the reduction o f CO, and unbumed H C emissions when using biodiesel fuel, while others have experienced just moderate increases in N O x emissions with unchanged CO and H C emissions ([3] and [7]), or even a reduction in all emissions ([8] and [9]). These, somehow contradictory, conclusions are caused by the non-uniformity o f the engine testing.

A comprehensive study was performed in order to establish how much influence different test

m otor

engine MAN D2566 MUM TAM BF4L515C

izm enjava delovne snovi gas exchange process

sesalna izvedba naturally aspirated

tlačno polnjenje turbocharged hlajenje

cooling

vodno water cooling

zračno air cooling zgorevalni postopek

com bustion process

M - postopek M - system

zgorevanje v zračnem vrtincu combustion in air swirl število valjev

num ber o f cylinders 6 4

prem er x gib bata

bore X stroke 125 mm x 1^5 mm 125 mm x 145 mm

gibna prostornina

total displacement 11413 ccm 7117 ccm

kom presijsko razmerje

compression ratio 17,5 15,8

dobava goriva fueling tlačilka fuel pump šoba nozzle izvrtine šobe nozzle holes

statični kot predvbrizga injection timing

neposredni vbrizg direct injection

BOSCH PES6A95D 410LS2542 BOSCH DLLA 5S834

1 X cp = 0,68 mm

23 °RG (°CA)

direktni vbrizg direct injection

BOSCH PES6P120A72 BOSCH DLLA 148S

4 x ® = 0,375 mm 16 °RG (°CA) P re g le d n ic a 1. Podatki o testnih motorjih

T a b le 1. Test engine specifications

P o sto p k a zgorevanja se razlikujeta že v f a z i p rip ra v e go rljiv e zm esi zrak - gorivo. V m o t o r j u TA M p o te k a z g o re v a n je v z račn em v rtin c u . G orivo se pri tlaku preko 800 bar vbrizga s k o z i brizgalo s štirimi izvrtinam i v razm erom a p litv o zgorevalno kom oro v čelu bata. Z račni v r tin e c , ki nastaja m ed polnjenjem v alja skozi ta n g e n tn o oblikovane polnilne kanale, zagotavlja h itro izhlapevanje drobno razpršenega goriva in m e š a n je z zrakom ter preprečuje sedanje goriva n a ste n e zgorevalne komore. V m otorju M AN je u p o ra b lje n t.i. postopek zgorevanja M. Gorivo se p ri tlak u do 500 bar vbrizga skozi brizgalo z e n o sam o izv rtin o . R azm ero m a strnjen cu rek g o riv a zadene stene krogelno oblikovane globoke z g o re v a ln e kom ore v čelu bata. K ar 95 odstotkov g o riv a se v obliki tankega sloja razlije po stenah z g o r e v a l n e k o m o re in p o tre b n a j e še v e č ja in te n z iv n o st zračnega vrtinca, s katerim se krepi iz h la p e v a n je sloja goriva in njegovo m ešanje z z r a k o m . U g o to v im o to re j la h k o , da se oba p o s to p k a zgorevanja m očno razlikujeta. M edtem k o s ta v p rim e ru T A M -o v eg a m o to rja v p liv p re d p la m e n ih fizik aln ih in kem ijskih pojavov en ak o v red n a, pa v prim em M AN -ovega m otorja

fiz ik a ln i pojavi iz h la p e v a n ja film a g o riv a in m ešan ja z zrakom prevladajo pojave kem ijske kinetike.

M ed o b e m a m o to rje m a o b s ta ja jo tu d i pom embne razlike v postopku izmenjave delovne snovi. TAM -ov m otor je tlačno polnjen in ima p rik lju č e n h la d iln ik p o ln iln e g a z ra k a . T la k i polnjenja zato presegajo 2 bar, temperature pa kljub hlajenju 50 °C. MAN-ov m otorje sesalne izvedbe, tlak in temperatura polnjenja sta enaka razm eram v okolici. M asa zraka, ki napolni valj, je zato v primeru TAM-ovega motorja neprimerno večja, kar o m o g o č a d o se g a n je v e č jih p re s e ž k o v z ra k a , potrebnega za zgorevanje.

TAM-ov m o to rje hlajen z zrakom, medtem ko im a M A N -ov m o to r vod n o h la je n je , zato sp rem em b e o b rem en itv e in p re d v se m v rtiln e frekvence precej manj vplivajo na tem peraturo v valju motorja in predvsem na razmere v zgorevalni komori v dobi zakasnitve vžiga.

V n a d a lje v a n ju p rik a z u je m o re z u lta te eksperimentalnih raziskav vpliva izbranega goriva na postopke zgorevanja in nastanek škodljivih snovi v obeh motorjih. Z namenom, da bi upoštevali tudi vpliv nastavitvte sistem a za dovod goriva, ki ga mnogi avtorji enostavno prezrejo, smo nastavitev sistem a za dovod goriva v prim eru TA M -ovega m otorja prilagodili čistem u biodizlu v prim eru M AN-ovega motoija pa gorivu D2.

1 EMISIJSKE ZNAČILKE

M e ritv e n a m o to rju so p o te k a le v preizkuševališču z zavornim dinam om etrom , ki om ogoča m erjenje obrem enitvenih in hitrostnih z n a č ilk m otorja. P oleg osnovnih o b rato v aln ih param etrov m otorja, kakor so vrtilna frekvenca m o to rja in tu rb o k o m p re so rja , n a v o r m o to rja , p r e to k z ra k a in g o riv a te r v iš in a z n a č iln ih tem p eratu r in tlak o v v polnilnem in izpušnem sistem u, smo m erili tudi koncentracijo plinskih deležev in saj v izpušnih plinih. K oncentracijo N O x sm o izm erili s kem olum iniscenčno m etodo, k o n cen tracijo n ezgorelih o g ljik o v o d ik o v HC s p lam en sk o io n izacijsk im d etek to rjem , stopnjo sajavosti z A V L-ovim m erilnikom , koncentracijo C O z m e to d o a b s o r b c ije n e d is p e r z ir a n e infrardeče svetlobe in koncentracijo 0 2 z Z r 0 2 zaznavalom .

U poraba biodizla nim a v p liv a na pretok zraka v sesalnem motorju, zato se zaradi manjše

evaporation and fuel vapour-air mixing dominate o v e r th e ch em ical k in e tic p ro c e sse s fo r any combustion in the MAN engine.

T h ere are som e in flu e n tia l differences betw een both test engines in term s o f the gas- exchange process. The TAM engine is turbocharged and eq u ip p ed w ith an intercooler. The intake pressures, therefore, exceed 2 bar, and the intake temperature is 50 °C. The MAN engine is naturally aspirated. The intake pressures and temperatures are, therefore, equal to the am bient conditions. Thus, the amount o f trapped fresh air in the cylinder is m uch higher in the TAM engine, which enables higher excesses o f air to be used.

The TAM engine is air cooled, while the M A N engine uses water cooling, which ensures a sm aller influence o f the engine speed and load on the in-cylinder temperature and other in-cylinder conditions during the combustion delay interval.

T he re s u lts o f th is e x p e rim e n ta l investigation into biodiesel fuel’s influence on the combustion processes and emission formations in both test engines are presented in the following. In order to consider any possible differences in fuel- in je c tio n strateg ies, o ften n eg le c te d by som e authors, the injection system set-up was purposely optimised for the application o f the biodiesel fuel in a TAM engine and for the application o f D2 fuel in a M AN engine.

1 EMISSION CHARACTERISTICS

Engine tests were performed on a test bed using a dynam om eter that m akes it possible to measure the engine’s speed and load characteristics. In addition to the basic operationing parameters of the engine, such as engine speed, turbocharger speed, engine load, air mass flow, fuel consumption, pressure and tem perature in both the intake and ex h au st system s, the concentration o f gaseous components and particulates in the exhaust gases w as also measured. The N Ox concentration was m easured using a chemiluminescence analyzer; a flame ionization detector was used for unbum ed hydro-carbon measurement; the particulates were m o n ito re d u sin g an AVL sm o k e m eter; the concentration o f CO was m easured w ith a non- dispersive infrared analyzer; and a Z r0 2 sensor was used for the oxygen concentration-measurement.

vrtilna frekvenca (1/min) Engine speed (rpm)

vrtilna frekvenca (1/min) Engine speed (rpm)

SLI. Vpliv goriva (biodizel DB, D2) na ustrezni razmernik zrak - gorivo

Fig. 1. Influence o f the applied fu e l (biodiesel BD and D2) on the equivalent air-fuel ratio

120%

100% 80% 60% 40% 20% 0%

motor TAM

□ CO

□ HC

□ NOx

■ saje soot

1200 1400 1600 1800 2000

vrtilna frekvenca (1/min) Engine speed (rpm)

motor MAN

vrtilna frekvenca (1/min) Engine speed (rpm)

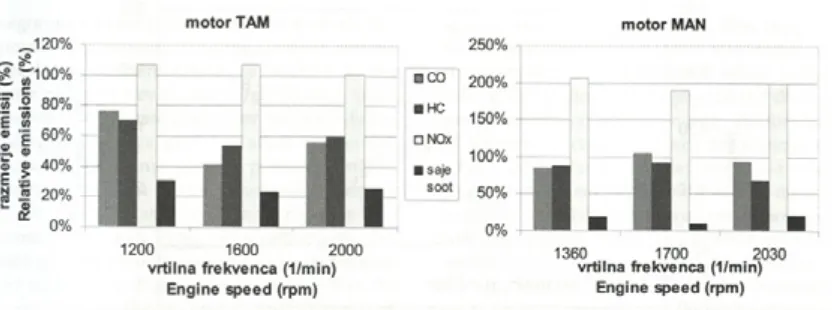

SI. 2. Relativna sprememba emisij, podana kot razmerje m ed specifičnimi emisijami, izmerjenimi z

biodizlom in gorivom D2 - zunanja značilka

Fig. 2. Relative emissions expressed as a ratio o f specific emissions with biodiesel and D2 fu e l - fu ll load potrebe po kisiku ustrezni razmernik zrak - gorivo

v M A N -ovem motorju poveča v povprečju za 7 o d s to tk o v (sl. 1). T udi v T A M -ovem tla č n o p o ln je n e m m otorju lahko na ta račun opazim o m a jh n o zvečanje ustreznega razm ernika zrak - g o riv o (do 2% ). Šestodstotno zm anjšanje moči m o to rja z uporabo biodizla [10] nam reč v tem prim eru zmanjša tudi moč plinske turbine, zato se vrtilna frekvenca turbokompresorja in pretok zraka zm anjšata, kar v okolici največjega navora (sl. 1; n = 1400 m i n 1) p riv e d e celo do 2 -o d sto tn e g a zm anjšanja ustreznega razmernika zrak - gorivo.

S lika 2 p rik azu je relativ n o sprem em bo e m is ij p o sa m e z n e g a m o to rja za ra d i u p o ra b e biodizla. Pri tem velja spomniti, da so nastavitve T A M -ovega m otorja optim irane za delovanje z biodizlom , medtem ko so nastavitve MAN-ovega m o to rja najprim ernejše za gorivo D2. O snovna ugotovitev je zmanjšanje emisij CO, HC in saj z uporabo biodizla, kar je pričakovano zaradi 10 %

aspirated engine. The equivalent air-fuel ratio in the MAN engine was, therefore, increased by 7 % (Fig. 1) due to the lower oxygen demand o f the biodiesel fuel. On the other hand the equivalent air- fuel ratio increased only slightly in the turbocharged TAM engine (Fig. 1). The reduction o f engine pow er [10] also influenced the decrease o f the turbocharger speed as air mass flows by 4 % and the resulting increase in the air-fuel ratio was just 2 %. Moreover, at peak torque (n = 1400 rpm), a 2 % reduction in the air-fuel ratio Was observed.

deleža kisika v gorivu, ki zniža primanjkljaj kisika v območjih, bogatih z gorivom, zavre nastanek saj in pospeši pojave oksidacije. Pri tem se pri MAN- ovem m otorju najm očneje (do 80 %) zm anjša koncentracija saj, ker se s 7 % povečanjem ustrezni razm em ik zrak - gorivo močno dvigne, nad t.i. mejo dima. Tudi emisije CO se prepolovijo, medtem ko v ečjega vpliva na že sicer m ajhne em isije HC biodizel nima. Pri TAM-ovem motorju se emisije saj in HC približno prepolovijo, m edtem ko je zm an jšan je em isij CO precej m anjše. P ovsem drugače pa vpliva uporaba biodizla na emisije NOx. M edtem ko se le-te v prim eru MAN-ovega motorja povečajo za 250 %, p a ostanejo pri TAM -ovem motorju enake, oziroma se celo nekoliko zmanjšajo. Ta razlika je vsekakor posledica nastavitve obeh motorjev, ki so za M AN-ov m otor optim alne za gorivo D2, za TAM-ov m otor pa za biodizel. Zaradi z m a n jša n ja o b rem en itv e m o to rje v na z u n a n ji značilki pri uporabi biodizla, je lahko primerjava na zunanji značilki nekoliko pristranska, na kar še posebej nakazuje zmanjšanje emisij NOx, zato smo m e ritv e p o n o v ili še p ri d e ln ih o b re m e n itv a h motorja.

Z a v sa k m o to r sm o z o b e m a v rs ta m a g o riv a p o s n e li h itr o s tn o z n a č ilk o p ri 7 0 -% o b r e m e n itv i. O s n o v n i k a z a lc i o b r a to v a n ja m otorja, to sta navor in m oč, se pri tem skoraj ne razlikujejo. Razlike v pretoku zraka so v m ejah m erilne negotovosti. Ponovno pa je z biodizlom zaradi m anjše potrebe po kisiku presežek zraka za 2,5 % večji, tokrat pri obeh m otorjih, saj pri e n a k i m o č i m o to rja b io d iz e l n e v p liv a n a delovanje turbokom presorja.

Sprem em bo specifičnih em isij pri 70-% o b rem en itv i p rik azu je slik a 3. P onovno je za M A N -o v m o to r zn ačiln o o b ču tn o zm an jšan je em isij saj, m edtem ko je zm anjšanje em isij CO in H C z b io d izlo m v p o v p re č ju le do 10 %. E m isije N O x p a so se za b io d iz e lsk o g o riv o ponovno podvojile. Povsem drugačna pa je slika pri TAM -ovem m otorju. Em isije N Ox so do 7 % večje za biodizel, m edtem ko je bilo na zunanji zn ačilk i prav nasprotno. To po trju je pravilnost hipoteze, da je treba izvesti prim erjavo goriv z v idika emisij v enakih razm erah, česar zunanja z n a č ilk a ne z a g o ta v lja . V p liv b io d iz la n a z m a n jš a n je em isij H C j e p o d o b e n k a k o r n a zunanji značilki, m edtem k o je zm anjšanje emisij C O in saj z b io d iz lo m o b č u tn e jš e k a k o r na zunanji značilki.

bonded in the biodiesel fuel reduces the deficit o f oxygen within the fuel-rich regions, hinders soot formation and accelerates the oxidation processes. In the MAN engine, the soot emissions were reduced the most (up to 4 times). The air-fuel ratio increased by 7 %, as shown previously, and, therefore, exceeded the so-called soot limit. CO emissions were halved, whilst the already very low HC emissions remained almost unchanged. In the TAM engine, both the soot and HC em issions w ere halved, w hilst the CO emissions decreased only moderately. With regard to the NOx emissions, both engines responded differently to the biodiesel fuel. The NOx emissions were almost doubled in the MAN engine, but were reduced in the TAM engine, which is undoubtedly the consequence o f the already-m entioned specific engine set-up. However, comparing engine emissions at full load may be misleading, since the use o f biodiesel fuel reduces the engine load and, therefore, m oderates any conditions for the formation o f emissions, especially N Ox emissions. The engine tests were, therefore, performed again under partial-load conditions.

The partial-load characteristics were measured at 70 % o f full load. It was possible, therefore, to maintain the same engine load with both fuels. The main operational parameters o f the engine, such as the e n g in e ’s to rq u e and pow er d id n o t d iffe r significantly when the D2 fuel was replaced by the biodiesel. The differences in air mass flow were within the measurement uncertainty interval for the naturally aspirated MAN as well as for the turbocharged TAM engine. The air-fuel ratio w as again higher b y approximately 2.5 % when biodiesel was used, this time for both engines, since the turbocharger operation was unaffected by the engine-load reduction.

motor TAM motor MAN

_ J 20% — S? g . ~1 0 0% :5 J 80% ■= m

E </>

® = 60% .2. <5

o ® 40%

E -I

K « 20%

*" S 0%

1200 1600 2000

vrtilna frekvenca (1/min) Engine speed (rpm)

vrtilna frekvenca (1/min) Engine speed (rpm)

Sl. 3. Relativna sprememba emisij, podana kot razmerje med specifičnimi emisijami, izmerjenimi z biodizlom in gorivom D2 - 70 % obremenitev

Fig. 3. Relative emissions expressed as a ratio o f specific emissions with biodiesel and D2 fu e l -p a r tia l (70%) load

2 VPLIV BIODIZLA NA ZGOREVANJE

2 INFLUENCE OF BIODIESEL ON COMBUSTION

P o te k s p r o š č a n ja t o p lo te m e d z g o r e v a n je m la h k o d o lo č im o z r a č u n s k o o b d e la v o in d ik a to rs k e g a d ia g ra m a m o to rja . Z ato sm o izm erili p o te k tlak a v v alju in gib igle vbrizgalne šobe na prvem v alju m otorja. P ri te m sm o za m e r je n je tla k a u p o r a b ili p i e z o e l e k t r i č n o z a z n a v a lo , z a g ib ig le in d u k tiv n o z a z n a v a lo in za m e rje n je le g e ročične gredi m o to rja o ptični kodirnik. V se tri s p re m e n ljiv k e sm o iz m e rili z ra č u n a ln iš k o p o d p r tim m e r iln im s is te m o m s fre k v e n c o zajem anja f = 100 kHz.

Za izračun poteka sproščanja toplote (KST) smo uporabili enotni brezrazsežni model zgorevanja [11]. Preračune smo za oba m otorja izvedli pri ra z lič n ih d e ln ih o b re m e n itv a h , p ri k a te rih posamezen motor dosega enake delovne parametre z obema vrstama goriv. Že uvodoma smo dejali, da se postopek zgorevanja v obeh motorjih razlikuje. Zato prikazujemo rezultate v nadaljevanju za vsak motor posebej.

The basic characteristics o f the combustion process can be obtained by the com putational processing o f the in-cylinder pressure trace. The in cylinder pressure- and inj ector-needle lift-time histories were, therefore, acquired from the first engine cylinder. A piezoelectric sensor was placed in the combustion chamber for pressure pick-up, an inductive sensor was used for the needle-lift measurement and an optical encoder was applied for the reference crank-angle position pick up. The signals from the sensors were acquired by a computer-aided data-acquisition system with a sampling rate o f 100 kHz per channel.

A one-zone zero-dimensional combustion model [11] w as used for the prediction o f the combustion heat-release rates, the so-called rate o f heat release (RHR) curves. The pressure traces acquired under different partial-load engine operating conditions, where the same engine load was obtained with both fuels, were processed. As stated in the introduction, the combustion processes of both tested engines differ significantly, thus the results of the RHR analysis are presented separately for each engine.

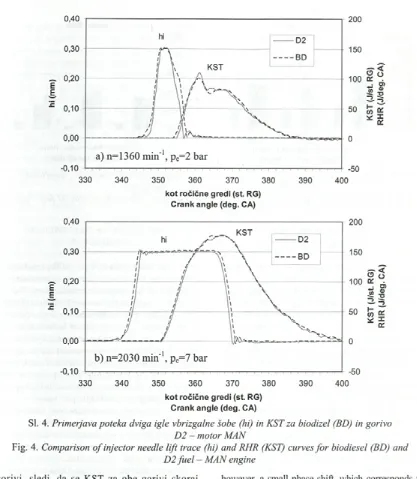

2 .1 V p liv b io d iz la n a z g o r e v a n j e v m o t o r j u M A N

Za prikaz smo izbrali dva skrajna primera delovnih režimov, majhno obremenitev pri nizki v rtiln i fre k v e n c i m o to rja (sl. 4 a) in v e lik o obremenitev motorja pri visoki vrtilni frekvenci (sl. 4 b). Iz prim erjave rezultatov, dobljenih za obe

2.1 I n f lu e n c e o f b io d ie s e l o n c o m b u s t io n in th e

M A N e n g in e

kot ročične gredi (st. RG) Crank angle (deg. CA)

kot ročične gredi (st. RG) Crank angle (deg. CA)

Sl. 4. Primerjava poteka dviga igle vbrizgalne šobe (hi) in K S T za biodizel (BD) in gorivo D 2 - m otor M A N

Fig. 4. Comparison o f injector needle lift trace (hi) and RHR (KST) curves fo r biodiesel (BD) and D 2 fu e l - M A N engine

g o riv i, siedi, da se K ST za obe gorivi skoraj povsem ujemajo. Opazim o lahko le m ajhen fazni odm ik, ki se ujem a s faznim odm ikom m ed gibom ig le v b rizg aln e šobe. Z ačetek v b rizg av an ja je zgodnejši, kadar je gorivo biodizel, ker pa je za enak srednji dejanski tlak m otorja potrebna večja k o ličin a biodizla (10 % nižja kurilnost) je trajanje v b riz g a v a n ja d aljše p rib liž n o 2 °RG na obeh režim ih. Pri veliki obrem enitvi in vrtilni frekvenci m o to rja (sl. 4 b) je ujem anje KST skoraj popolno. To n a k a z u je na d ejstv o , da m ed z a k a sn itv ijo v žig a, ki ga sestavljata fizikalni del, v ezan na p o jav e u p arjan ja goriva, m e šan ja z zrak o m in

segrevanja do tem perature vžiga, in kem ijski del, p o v e z a n s sa m im v ž ig o m g o riv a , m o čn o prevladuje fizikalni del, saj se biodizel, ki ima v išje cetansko število, kaj hitreje ne vžge kakor gorivo D2 in je zato zakasnitev vžiga neodvisna o d u p o ra b lje n e g a g o riv a . Z a ra d i razm ero m a p o č a sn ih fizik a ln ih pojavov p rip rav e g o rljiv e zm esi zraka in par goriva, je nastanek hom ogene zm esi v dobi zakasnitve vžiga zavrta, zato KST nim a dveh vrhov. Drugi vrh se začne pojavljati šele pri manjših obrem enitvah i n j e najm očnejši pri nizki vrtilni frekvenci m otorja (sl. 4 a). Pri te m j e d e le ž z g o re v a n ja p o p re j p o m e š a n ih reaktantov le m alenkostno manjši za biodizel, kar p a lahko pripišem o tudi negotovosti m erjenja in postopka glajenja indikatorskega diagrama. Zato lahko z dokaj veliko verjetnostjo sklenemo, da u p o r a b a b io d iz la v M A N -o v e m m o to rju s p o stopkom zgorevanja M ne vpliva na hitrost sproščanja toplote (KST), da pa zagotavlja 10- odstotni delež kisika v gorivu neprim erno boljše pogoje za popolnejšo oksidacijo m olekul goriva (z a to m anjše em isije C O , HC in saj), k ar pa u s tv a rja v išje lo k aln e tem p eratu re in pospeši nastanek NOx.

2 .2 V p liv b io d iz la n a z g o r e v a n j e v m o t o r j u T A M

Ponovno sm o za prikaz (sl. 5) izbrali dva s k ra jn a d e lo v n a rež im a . K ST za b io d iz e l in g o riv o D2 se p re c e j m anj u je m a jo k a k o r v p r im e r u M A N -o v e g a m o to r ja . O b fa z n e m o d m ik u se ja v lja jo tudi pom em bne ra zlik e v o b lik i KST. Fazni odm ik pa ni več le posledica o dm ika m ed gibom igle vbrizgalne šobe, am pak tu d i sk ra jša n e dobe z a k a sn itv e v žig a. To pa p o m eni, da je postal kem ijski delež zakasnitve v ž ig a pom em bnejši, zaradi česar se z uporabo b io d iz la z v išjim cetanskim številom pojavijo pom em bne razlike v prvem delu KST. H itrejši v ž ig b io d iz la , to rej k ra jša z a k a sn ite v v žig a, z n iž a d e le ž h o m o g e n e g a z g o re v a n ja p o p re j p o m e š a n ih r e a k ta n to v in s k o ra j p re p o lo v i n a jv išjo h itro st hom ogenega zgorevanja. Z ato p a se p o v eča d elež d ifu zn eg a z g o rev an ja, ki p o tek a z večjo jak o stjo .

P ri m a n jši o b re m e n itv i (sl. 5 a) j e za g o r iv o D 2 z n a č iln o iz r a z ito p o d ro č je h o m o g e n e g a z g o re v a n ja z v elik im i h itro stm i z g o re v a n ja . J a v lja se tu d i p ri b io d iz lu , a je

ignition, which is the same for both fuels. Biodiesel, however, has a higher cetane index than D2 fuel, and should accelerate combustion and reduce ignition delay if the significance o f the physical and chemical parts of the ignition delay is the same. The formation o f premixed reactants is slowed down during the ignition delay, due to the relatively slow-running physical processes o f the com bustible-m ixture formation. The RHR curve then appears in most cases with only one peak. A double-peak HRH curve only appears for very low loads, and is most clearly seen at low engine speeds (Fig. 4 a). The portion of premixed combustion with biodiesel is only slightly lower under this regime, and the differences in the RHR curve for both fuels may be attributed to the measurement uncertainty or pressure-trace smoothing. It can be concluded, therefore, that the application o f biodiesel fuel in a M AN engine, w hich em ploys the M- combustion process, does not influence the rate o f heat release (RHR). The oxygen bonded in the biodiesel fuel, however, creates much better conditions for a more com plete oxidation o f the fuel m olecules (therefore, lower soot, CO and HC emissions), which increases the local flame temperatures and accelerates NOx formation.

2 .2 I n f lu e n c e o f b io d ie s e l o n th e c o m b u s t io n in

th e T A M e n g in e

Two extreme engine operating regimes were selected for the comparison (Fig. 5). The RHR curves of the TAM engine differ substantially for different fuels in comparison to the MAN engine. In addition to the phase shift, there are distinguishable differences in the RHR curve’s shape. Moreover, the phase shift is not caused by the injector-needle lift shift only, but also by the reduced ignition delay of the biodiesel fuel. This implies that the chemical part ofthe ignition delay became more influential in the TAM engine and, therefore, the application of biodiesel fuel, which has a higher combustibility (cethane index) than D2 fuel, caused different combustion rates in the initial phase of combustion. The biodiesel fuel ignited quicker, thus the ignition delay was shorter, the quantity of premixed reactants decreased, which then reduced the share of fuel burned with the premixed flame, and lowered the maximum rate of heat release by almost 50 %. The share of combustion with diffusion flame was, therefore, higher, and the combustion intensity with the diffusion flame increased.

i

I

w K

kot ročične gredi (st. RG) Crank angle (deg. CA)

Sl. 5. Primerjava poteka dviga igle vbrizgalne šobe (hi) in K S T za biodizel (BD) in gorivo D 2 - motor TAM

Fig. 5. Comparison o f injector needle lift trace (hi) and RHR (KST) curves fo r biodiesel (BD) and D2 fu e l — TAM engine

n je g o v a ja k o s t m a n jša . R a z lik a je p o sle d ic a ra zličn ih zak a sn ite v v ž ig a o beh goriv. Z arad i večje vnetljivosti b io d izla so zakasnitve vžiga k ra jše , m a n jša je k o lič in a p o p rej p o m e ša n ih reaktantov, ki nastajajo v času zakasnitve vžiga, z a to j e d e le ž g o riv a , k i z g o ri s h o m o g e n im p lam en o m tudi m an jši, p re d v se m p a so v tej z a č e tn i fa z i m a n jše h i t r o s t i z g o r e v a n ja . V p o d ro čju d ifu zijsk eg a zg o rev an ja, ki sledi, so hitrosti zgorevanja za obe gorivi precej manjše (sl. 5 a) in pri obeh obrem enitvah je difuzijsko z g o r e v a n je b io d iz la m o č n e jš e , k a r la h k o p o ja s n im o z n e k o lik o b o ljš o v n e tljiv o s tjo biodizla, predvsem p a z dejstvom , da je zaradi

m anjše p o treb e po k isik u n a sta ja n je g o rljiv e zm esi v zgorevalnem prostoru hitrejše.

Pri večjih obrem enitvah (sl. 5 b) postaja hom ogeno zgorevanje vse manj izrazito in ga pri veliki vrtilni frekvenci komaj še opazimo. Njegov delež se prepolovi. To je posledica zm anjšanja z a k a s n itv e v ž ig a , k i se p ri p o v e č e v a n ju o b re m e n itv e tla č n o p o ln je n e g a T A M -o v eg a m otorja zmanjša. Zmanjšanje deleža homogenega zgorevanja in njegove jakosti pa pomembno vpliva na znižanje lokalnih tem peratur in nastanek NOx. Z ato se v tem prim eru skupne em isije N O x ne p o v ečajo tako m očno k akor v prim eru M AN- ovega motorja in ostajajo na ravni emisij NOx ob u p o rab i goriva D2, m edtem ko povečan delež kisika v biodizlu izboljša oksidacijske pogoje in zmanjša koncentracije CO, HC in saj v izpušnih plinih (sl. 3).

3 SKLEP

V prispevku so prikazani rezultati raziskav vpliva biodizla na postopek zgorevanja v dizelskem m otorju, vpliva na osnovne parametre delovanja m otorja in na emisijo škodljivih snovi. Raziskave smo izvedli na dveh dizelskih motorjih z različnima postopkoma zgorevanja, na sesalnem motoiju MAN in tlačno polnjenem m otorju TAM. Pri tem smo nastavitve sistem a za dovod goriva na m otorju M AN prilagodili uporabi D2 goriva, na motorju TAM pa biodizlu. Ugotovitve, ki slede iz primerjave z rezultati, dobljenimi z gorivom D2, so naslednje: a ) e m is ij e

- z uporabo biodizla se emisije CO, HC in saj zmanjšajo na vseh obratovalnih režim ih in pri o b e h m o to rjih . P ri te m se n a jm o č n e je zmanjšajo emisije saj. Zmanjšanje emisij CO je večje pri M AN-ovem motorju, zmanjšanje HC pa pri TAM-ovem motorju

- em isije N O x pri M A N -ovem m otorju se z uporabo biodizla podvojijo in se ne zmanjšajo niti pri delni 70 % obremenitvi, pri TAM-ovem m otorju pa so z uporabo biodizla na zunanji značilki zaradi nižjih obremenitev emisije NOx manjše, medtem ko pa se pri izenačenih pogojih delovanja (70% obrem enitev) dvignejo nad vrednosti za gorivo D2.

b ) p o s t o p e k z g o r e v a n j a

Vpliv je v največji meri odvisen od postopka nastanka zmesi gorivo - zrak, zato občih ugotovitev,

the biodiesel is more intensive at both engine loads. The explanation for this is a higher cetane index, and, in particular, the lower oxygen demand o f biodiesel, which intensifies the formation o f a combustible mixture and its combustion with the diffusion flame.

H ie portion of premixed combustion is less explicit at high engine loads (Fig. 5 b), and for biodiesel it is already hardly noticeable. Its share is reduced by 50 % for both fuels due to the shorter ignition delay, which is characteristic for high engine loads and turbocharged engines. The reduced share o f the premixed flame and its intensity have an influence on the reduction in local temperatures and decelerate NOx formation. The increase o f NOx emissions with biodiesel fuel is, therefore, far from that encountered by the M AN engine. The oxygen bonded in the biodiesel fuel, however, aids the oxidation o f fuel molecules and, therefore, produces lower soot, CO and HC emissions (Fig. 3).

3 CONCLUSION

This paper presents experimental results from research on the influence o f biodiesel fuel on the combustion process, emission formation and engine operating parameters o f a diesel engine. This research was performed using naturally aspirated MAN and tu rb o c h a rg e d TAM en g in es, b o th em ploying different combustion processes. The injection system set-up was purposely optimised for the application o f D2 fuel in the MAN engine and for the application o f biodiesel fuel in the TAM engine. The following conclusions can be made from a comparison o f those results obtained for both biodiesel and D2 fuels: a ) e m is s io n s

- the emissions o f CO, HC and soot are reduced under all engine operating regimes in both engines when the biodiesel fuel is used. The reduction of soot em issions is the highest. CO emissions decrease more in the MAN engine, while HC emission reduction is higher in the TAM engine. - the NOx emissions are doubled in the MAN engine

and, moreover, do not decrease even under a partial 70% load when the biodiesel fuel is applied. In the TAM engine, specific NOx emissions decrease at full load and increase slightly over the values for D2 fuel under equal load conditions (70 % load) when the biodiesel fuel is applied.

b ) c o m b u s t io n p r o c e s s

razen da se poveča ustrezni razm em ik zrak - gorivo, ne moremo dati;

- za postopek M (motor M AN) velja:

- v dobi zakasnitve vžiga in m ed zgorevanj em p re v la d u je jo fiz ik a ln i p o ja v i n ad kemijskimi,

- potek zgorevanja se ne sprem eni - KST ostaja skoraj nespremenjena za obe gorivi; - za p o sto p ek zgo rev an ja v zračnem v rtin cu

(motor TAM) pri uporabi biodizla velja: skrajša se zakasnitev vžiga,

- ja k o st zgorevanja predhodno pom ešanih reaktantov se zmanjša do 40 %,

- povečata se ja k o st in delež difuzijskega zgorevanja,

- trajanje zgorevanja ostaja enako,

- zm anjša se gradient višanja tlaka, kar je posebej izrazito pri manjših obremenitvah motorja, zato je tek motoija bolj gladek in tih.

generalization o f findings can be made. The conclusions for the individual engines are as follows:

- M - system combustion (MAN engine) - the p h y sical processes p rev ail ov er the

chemical ones during ignition delay, - the combustion process is unaltered - the

rate o f heat release (RHR curves) is almost the same for both fuels;

- com bustion in air swirl (TAM engine) when using biodiesel fuel:

- the ignition delay is reduced ,

- the intensity o f the premixed combustion is reduced by up to 40 %,

- the intensity and share o f the diffusion combustion is increased,

- the combustion duration remains unchanged, - the combustion pressure gradient is reduced and,

therefore, the engine’s operation is smoother and quieter, especially for low engine loads;

4 LITERATURA 4 REFERENCES

[1] M iyamoto, N., Ogawa, H., Nurun, N ., Obata, K., Arima, T., Smokeless, low NOx, high thermal efficiency, and low noise diesel combustion w ith oxygenated agents as main fuel, SAE p a p er 980506 [2] Giacomo, N.D., Beatrice, C., Bertoli, C., Diesel combustion improvements by the use o f oxygenated

synthetic fuels, SAE p a p er 972972

[3] Alam, M., Song, J., Acharya, R., Boehman, A., Combustion and emissions performance o f low sulfur, ultra low sulfur and biodiesel blends in a DI diesel engine, SAE paper 2004-01-3024

[4] Cowlely, L.T., Shadling, R.J., Doyon, J., The influence o f composition and properties o f diesel fuel on particulate emissions from diesel engines, SAE paper 932732

[5] Nabi, M.N., Shahadat, M.M.Z., Rahman, M.S., Beg, M.R.A., Behavior o f diesel combustion and exhaust emission with neat diesel fuel and diesel-biodiesel blends, SAE paper 2004-01-3034

[6] Sanatore, A., Cardone, M., Rocco, V., Prati, M. V., A comparative analysis o f combustion process in DI diesel engine fueled w ith biodiesel and diesel fuel, SAE paper 2000-01-0691

[7] May, H., Hattingen, U., Theobald, J., Weidmann, K., Koenig, A. (1998) Untersuchung des Betriebs und Abgasemissiosverhaltens eines Dieselmotors m it Oxidationskatalysator, M TZ M otortechnisches Zeitschrift 59 (1998) 2, str.: 1 1 2 -1 2 3

[8] Hribernik, A. (2006) Vpliv biodizla na vbrizgavanje goriva, zgorevanje, nastanek emisij in značilnice dizelskega motorja z neposrednim vbrizgom, Strojniški vestnik letnik 52, št. 1, 2006, str.: 3 do 14 [9] Yamane, K., Ueta, A., Shimamoto, Y. (20019 Influence o f physical and chemical properties o f biodisel

fuel on injection, com bustion and exhaust em ission characteristics in a DI-CI engine, The Fifth International Symposium on Diagnostics and M odeling o f Combustion in Internal Combustion Engines (COMODIA 2001), July 1-4, 2001, Nagoya, str.: 402 do 409

[10] Hribernik, A., Kegl, B. (2007) Influence o f biodiesel on the combustion and emission formation in a direct injection (DI) diesel engine, Energy & Fuels, 2007, 21, str. 1760 do 1767

N aslov avtorjev: prof. dr. Aleš Hribernik Authors’ Address: prof. dr. Breda Kegl

Univerza v Mariboru Fakulteta za strojništvo Smetanova 17

2000 Maribor

ales. hribem ik@ uni-m b. si breda.kegl@uni-mb.si

Prejeto:

R e c e iv e d : 30.7.2007

Sprejeto:

A c ce p te d : 28.9.2007

Prof. Dr. Aleš Hribernik Prof. Dr. Breda Kegl University o f Maribor Faculty o f Mechanical Eng. Smetanova 17

2000 Maribor, Slovenia ales.hribemik@uni-mb.si breda.kegl@uni-mb.si

O dprto z a diskusijo: 1 leto