Katarzyna Hys* Katarzyna Hys

ISO/TS 16949 analysis of the current trends

ISO/TS 16949 analysis of the current trends

Introduction

Thanks to the constant globalisation process and the systematically encountered fierce competition on international markets, the change in the location of production processes has become a common practice for entrepreneurs representing the automotive sector all over the world. At the same time, the phenomenon of capital concentration can be observed in the automotive sector. This concentration can be seen in the form of nu-merous fusions and acquisitions continuously taking place on this market, the implication of which are newly-formed entities or capital groups [Hys, 2015, p. 28; Calado et al., 2014, pp. 23–34; Chang et al., 1999, pp. 407–418; Ostadi et al., 2010, pp. 494–511].

The occurring capital concentration and relocation of production en-tail further consequences. Entrepreneurs from the automotive sector act-ing in the environment of dispersed business entities have to unify opera-tion standards, including quality standards. In relaopera-tion to the above, in this paper, the author will consider the issue of quality standards which are used in the enterprises of the automotive sector [Przybytniowski, Buczma, 2014, pp. 46–53; Przybytniowski, 2012, pp. 33–56; Reid, 2005, pp. 31–38; Zakuan et al., 2009, pp. 439–443; Rodríguez-Rocha et al., 2009, pp. 100–106].

The aim of the paper is to present and analyze trends in implementa-tion of quality certificates that conform to the ISO/TS 16949. Data prepara-tion and analysis of inference was performed based on desk research methods. Data were collected on the basis of source materials including such as communications, trade studies, reports, companies and research institutions.

1. Methodology

The preparation of data, their analysis and drawing conclusions have been made on the basis of the desk research method. The data was gath-ered by means of an analysis of source materials such as, among others: * Ph.D., Faculty of Production Engineering and Logistics, The Opole University of Tech-nology, Luboszycka 5, 45-036 Opole, k.hys@po.opole.pl

announcements, press releases, reports for industries, publicly available reports of companies and research institutions, information from the In-ternet.

2. Technical Specification Identification ISO/TS 16949 2.1. Idea ISO/TS 16949

The range of solutions in the scope of quality applied by particular concerns caused that there was a huge difference in the execution quality between particular cars. This issue is particularly important in case of the automotive sector as the structure of this market is quite specific. We can differentiate two groups of entities: car manufacturers (OEM, VM) that create the final product and sub-suppliers (e.g. Tier 1 supplier) that supply parts indispensable to assemble a vehicle.

In case of Poland, particular concerns use parts coming from about 80% of independent manufacturers in the production process of vehicles. The parts are produced by car manufacturers in 20%. The other parts used for the car manufacturing come from independent manufacturers that make an important contribution to the final product formation process [Bran¿a motoryzacyjna w Polsce, 2014, p. 17]. In reality, such a market phy-siognomy meant many discrepancies in the scope of quality requirements in relations between final product manufacturers and independent manu-facturers of parts. This is why, the situation on the market had an influ-ence on the creation of the need in the scope of universalisation of the quality standard for all entities being the part of the supply chain.

Elaboration of a standard which provided for consistent criteria in the scope of requirements and assessment for all sub-suppliers has come into force in 1999 [Kartha, 2004, p. 336; bsigroup.com, 2015]. The technical specification ISO/TS 16949 [2009] is a consensus among numerous solu-tions of local character for enterprises from the automotive sector in a given country [Wolniak, Szymañski, 2006, pp. 70–71]. It means that the technical specification ISO/TS 16949 is a consequence of the require-ments standardisation process in the scope of quality management for the automotive sector replacing the solutions such as: VDA 6.1 (Verband Der Automobilindustrie), QS 9000 (Quality System), AVSQ (Associazione nazionale dei Valutatori di Sistemi Qualita`) or EAQF (Stands for evalua-tion, aptitude, quality and supplier) [Bevilacqua et al., 2011, pp. 841–866; Johnson et al., 2007, pp. 41–56; Joshi et al., 2013, pp. 151–161].

2.2. Basic description of ISO/TS 16949

The technical specification ISO/TS 16949 is synchronised with the ISO 9001 standard. It establishes detailed requirements concerning the quality management system during the production process as well as assembling and maintenance of products connected with the automotive industry. The concentration of specification requirements is focused on the activi-ties in the scope of manufacturing and rendering services, supervising the monitoring and measuring equipment, analysis and improving the quality management system in the automotive industry by means of undertaking preventive measures limiting the creation of inconsisten-cies and eliminating discrepaninconsisten-cies and losses in the supply chain [ISO/TS 16949:2009, 2009]. Moreover, the diffusion of ISO/TS 16949 and ISO 9001 in the scope of client’s detailed requirements provides tools of purposeful offer formation by VM. The vehicles manufacturers’ offer makes it possi-ble to skillfully combine qualitative technical aspects of a vehicle with marketing elements already at the stage of projecting.

The technical specification ISO/TS 16949 in relation to the ISO 9001 requirements introduces:

– specification of the terminology concerning the automotive industry specificity (3),

– extension of requirements concerning documentation in the scope of the necessity of introducing supervision over the technical docu-mentation (4),

– as far as responsibility, rights and communication are concerned, a need to appoint the client’s representative has been noticed (5.5), – as far as competence, consciousness and training are concerned,

the necessity of specifying the staff qualifications to design the prod-uct, documenting requirements in the scope of staff training and train-ing at work, determintrain-ing a proper motivation process for the organisa-tion’s employees have been taken into consideration (6.2.2),

– as far as designing and development of particular parts are concerned, standards in the scope of supervision over these phases and docu-menting their proper performance have been determined (7).

3. Trends – overview of global data

The concentration of the efforts of the automotive companies’ em-ployees on the general creation and improvement of quality standards in each of activity areas gives a chance to gain an advantage over other

concerns. At the same time, it is the way to increase efficacy and strengthen a competitive position in the international environment.

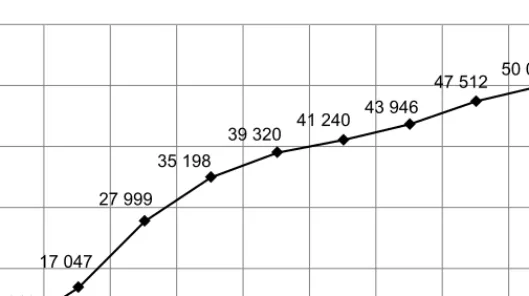

An analysis of existing trends provides one of the objective proofs to confirm the thesis that uniform standards in the scope of quality manage-ment in the automotive sector enterprises provide authentic results for en-trepreneurs. An analysis of quantitative data concerning the number of is-sued ISO/TS 16949 certificates makes it possible to draw the following conclusions that the number of certified quality systems being in accor-dance with the ISO/TS 16949 standard has been showing a positive trend all over the world for the last 10 years (figure 1).

Figure 1. The total number of ISO/TS 16949 – Quality management systems – an overview of the world

Source: Own elaboration based on [The ISO Survey of Management System Standard Cer-tifications, 2013].

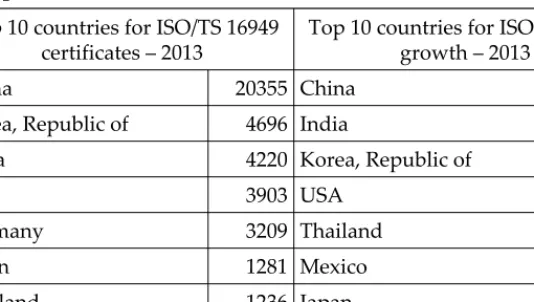

The number of issued ISO/TS 16949 certificates increases each year all over the world. The number of ISO/TS 16949 certificates increased by 7% all over the world in 2013 when compared to 2012 [The ISO Survey of Ma-nagement System Standard Certifications, 2013]. The biggest number of certificates was issued in 2013 in China and the increase is here the big-gest when compared with the preceding year (table 1). An analysis of nu-merical data makes it possible to notice the fact that Chinese enterprises were awarded as many as 38% of the total number of certificates issued all over the world in the year 2013. However, it is worth noticing that in

com-parison of the general number of ISO/TS 16949 certificates, numerical data for 80 countries located all over the world have been presented.

The result can be seen in the production volume in given countries. In case of China, the production growth by 9,6% was noticed in 2013 when compared to the preceding year. Although Brazil, Russian Federation and India have noticed a decrease in the production level, their production level still largely exceeds a million of vehicles a year [The International Or-ganization of Motor Vehicle Manufacturers, 2015]. Thanks to such a pro-duction level these countries are important business partners in the auto-motive sector.

Table 1. Top countries for ISO/TS 16949 certificates (2013)

No. Top 10 countries for ISO/TS 16949certificates – 2013 Top 10 countries for ISO/TS 16949growth – 2013

1 China 20355 China 2380

2 Korea, Republic of 4696 India 427

3 India 4220 Korea, Republic of 242

4 USA 3903 USA 92

5 Germany 3209 Thailand 89

6 Japan 1281 Mexico 84

7 Thailand 1236 Japan 44

8 Mexico 1205 Russian Federation 43

9 Brazil 1195 Turkey 43

10 Italy 1171 Taipei, China 41

Source: [The ISO Survey of Management System Standard Certifications, 2013].

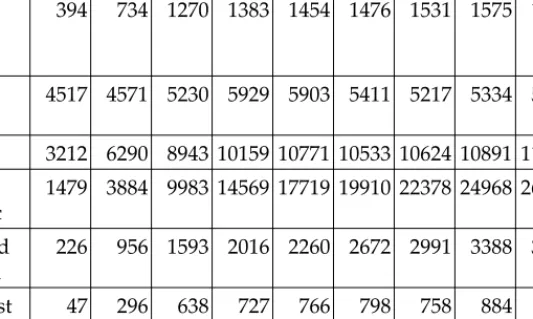

Detailed data concerning the number of ISO/TS 16949 certificates have been shown in the figure (table 2). Among the countries which develop their activity dynamically in the scope of adjusting quality standards in accordance with ISO/TS 16949 specification there are mainly countries of the East Asia and the Pacific. For countries located on the other continents the level of certification takes a stable increasing ten-dency. The enterprises in the automotive sector located in Europe have a stable qualitative policy [Hys, 2014a, pp. 33–35; Hys, 2014b, pp. 34–41].

Table 2. ISO/TS 16949 – Quality management systems – overview in the world Year 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 Africa 144 316 342 415 447 440 447 472 464 479 Central / South America 394 734 1270 1383 1454 1476 1531 1575 1581 1585 North America 4517 4571 5230 5929 5903 5411 5217 5334 5410 5592 Europe 3212 6290 8943 10159 10771 10533 10624 10891 11017 11263 East Asia and Pacific 1479 3884 9983 14569 17719 19910 22378 24968 26985 29831 Central and South Asia 226 956 1593 2016 2260 2672 2991 3388 3817 4260 Middle East 47 296 638 727 766 798 758 884 797 713 Total 10019 17047 27999 35198 39320 41240 43946 47512 50071 53723 Source: [The ISO Survey of Management System Standard Certifications, 2013].

Such a situation is connected with a relatively stable number of enter-prises in the automotive sector, whereas countries such as North America, Central and South Asia, Central/ South America, Middle East and Africa develop production in the scope of automotive industry to a much lower extent. This is why, quantitative data concerning the number of awarded ISO/TS 16949 certificates only confirm the fact that these countries do not count much in the global production of vehicles.

Conclusion

Quality certificates and their changes in time are subjects of research and are very interesting [Sampaio et al., 2009, pp. 38–58]. This paper aims at presenting a preliminary analysis in the scope of dynamics of the ISO/TS 16949 certificates number received by enterprises all over the world. On the basis of data, it is possible to draw conclusions that the ISO/TS 16949 standard obtained a general approval in the entrepre-neurs’ community in the automotive sector. Due to the fact that the stan-dard has been functioning only for several years, the dynamics of its im-plementation in a worldwide perspective is quite impressive. The factors which led to the creation of ISO/TS 16949 requirements and guidelines seem to be the causes of such a situation. The factors which have an influ-ence on the quality systems certification process can be of different origin.

Entrepreneurs see economic aspects in the implementation of the quality certificate. Organisation aims which have an influence on the efficacy of the company’s operation are also mentioned. Entrepreneurs’ calcula-tions of (non)benefits and threats connected with the certification process outweighed the costs. The main aim of the enterprise’s operation is to gain advantage over highly competitive companies by means of improving the quality of their products and thanks to that, among others:

– increase the market share, – diversify the customer’s base,

– increase actions focused on meeting market trends (among others re-search carried out in the scope of environmental protection, security, – use of alternative energy resources),

– increase of the current potential of resources (among others economic, intellectual, material, informative, technological) and

– achieve the operational synergy by a given organisational unit. The quality systems certification in enterprises of the automotive sec-tor in accordance with ISO/TS 16949 is acknowledged by all car manufac-turers all over the world. The fact that a given company has a certificate being in accordance with ISO/TS 16949 is an important argument in busi-ness talks. This standard introduces a common ground for all participants of the supply chain.

References

1. Bevilacqua M., Ciarapica F.E., Giacchetta G., Marchetti B. (2011), Im-plementation of a quality procedure based on Delphi method and the ISO/TS 16949: 2009 in the production of stainless steel tubes for automotive exhaust systems, “International Journal of Quality & Reliability Management”, Vol. 28, No. 8.

2. Bran¿a motoryzacyjna w Polsce. Liczby podsumowania analizy(2014), Sto-warzyszenie Dystrybutorów i Producentów Czêœci Motoryzacyjnych. 3. Calado R. D., Silva M. B., Silva Boa Sorte Oliveira A. A., Spagnol G. S.,

Sarantopoulos A., Li L. M. (2014),Defining quality and maturity level ap-plying the grey system and the method for automotive enterprises diagnosis, “American Journal of Theoretical and Applied Statistics”, Vol. 3, No. 6–1. 4. Chang T-Z., Mehta R., Chen S-J., Polsa P., Mazur J. (1999), The effects

of market orientation on effectiveness and efficiency: the case of automotive distribution channels in Finland and Poland, “Journal of Services Market-ing”, Vol. 13, Issue 4/5.

5. http://www.bsigroup.com/pl-PL/Zarzadzanie-Jakoscia-w-Przemysle -Motoryzacyjnym-ISO-TS-16949, accessed 09.01.2015.

6. Hys K. (2014a), Tools and methods used by the Polish leading automotive companies in quality management system. Results of empirical research, “Journal of Achievements in Materials and Manufacturing Engineer-ing”, Vol. 63, No. 1.

7. Hys K. (2014b), Dzia³ania promocyjne producentów i dealerów pojazdów samochodowych w Polsce, „Marketing i Rynek”, nr 6.

8. Hys K. (2015), Zjawisko koncentracji i delokalizacji w bran¿y motoryza-cyjnej(The phenomenon of concentration and relocation in the automotive in-dustry), „Handel Wewnêtrzny”, nr 5.

9. ISO/TS 16949:2009 Quality management systems – Particular require-ments for the application of ISO 9001:2008 for automotive production and relevant service part organizations (2009), http://www.iso.org/ iso/catalogue, accessed 17.12.2014.

10. Johnson D. M., Sun J., Johnson M.A. (2007),Integrating multiple manu-facturing initiatives: challenge for automotive suppliers, “Measuring Busi-ness Excellence”, Vol. 11, No. 3.

11. Joshi D., Nepal B., Rathore A.P.S., Sharma D. (2013), On supply chain competitiveness of Indian automotive component manufacturing industry. “International Journal of Production Economics”, Vol. 143.

12. Kartha C.P. (2004), A comparison of ISO 9000:2000 quality system stan-dards, QS9000, ISO/TS 16949 and Baldrige criteria, “The TQM Maga-zine”, Emerald Group Publishing Limited, Vol. 16, No. 5.

13. Ostadi B., Aghdasi M., Kazemzadeh R.B. (2010),The impact of ISO/TS 16949 on automotive industries and created organizational capabilities from its implementation, “Journal of Industrial Engineering and Manage-ment JIEM”, Vol. 3, No. 3.

14. Przybytniowski J.W. (2012),Odpowiedzialny biznes nie dla wszystkich, in:

Zarz¹dzanie procesami restrukturyzacji. Koncepcje-strategie-analiza, Boro-wiecki R., Jaki A. (Eds.), Uniwersytet Ekonomiczny w Krakowie, Ka-tedra Ekonomiki i Organizacji Przedsiêbiorstw, Fundacja Uniwer-sytetu Ekonomicznego, Kraków.

15. Przybytniowski J. W., Buczma S. E. (2014), Konkurencyjnoœæ przedsiê-biorstw w dobie globalizacji, „Ekonomika i Organizacja Przedsiêbior-stwa”, nr 10(777), Warszawa.

16. Reid R.D. (2005),TS 16949 – where did it come from?, “Quality Progress”, Vol. 38, No. 3.

17. Rodríguez-Rocha B.D., Castillo-Barrera F.E., López-Padilla H. (2009),

Knowledge Capitalization in the Automotive Industry using an Ontology based on the ISO/TS 16949 standard, Electronics, Robotics and Automo-tive Mechanics Conference, 20–25 September.

18. Sampaio P., Saraiva P., Guimaraes R.A. (2009),ISO 9001 certification re-search: questions, answers and approaches, “International Journal of Qual-ity and ReliabilQual-ity Management”, Vol. 26, No. 1.

19. The International Organization of Motor Vehicle Manufacturers http://www.oica.net, accessed 16.01.2015.

20.The ISO Survey of Management System Standard Certifications – 2013. Executive summary(2013), http://www.iso.org, accessed 12.12.2014. 21. Wolniak R., Szymañski J. (2006),Wykorzystanie narzêdzi statystycznych

do analizy procesu w produkcji wielkoseryjnej na przyk³adzie przedsiêbior-stwa motoryzacyjnego, „Zarz¹dzanie Przedsiêbiorstwem”, nr 2.

22. Zakuan N.M., Yus of S.M., Shaharou A.M. (2009),The Link between To-tal Quality Management and Organizational Performance in Malaysian Au-tomotive Industry: the mediating role of ISO/TS16949 efforts, IEEE Interna-tional Conference on Industrial Engineering and Engineering Management.

Abbreviations

OEM – Original Equipment Manufacturer VM – vehicle manufacturer

Tier 1 supplier – direct supplier

Tier 2 – the second sub-supplier in the chain, etc.

ISO/TS 16949 analysis of the current trends (Summary)

The companies of automotive industry has always shown a particular inter-est the issue of quality management systems. The consequence of the process of universalisation of quality systems in the automotive industry was to develop a single standard. A single reference model led to define Technical Specification (TS) 16949 by International Organization for Standardization (ISO) aimed at rep-resenting a comprehensive quality management system for the global automotive industry. This paper studies the global evolution and diffusion of this technical specification, observing its impact on local economies. The findings are sup-ported by empirical data.

Keywords