Volume-7 Issue-2

International Journal of Intellectual Advancements

and Research in Engineering Computations

A review study on asphalt binders

S. Loganayagan

1, S. Suvetha

2, C. Vishalachi

21

Assistant Professor,

2Student,

2Student

Department of Civil Engineering, Bannari Amman Institute of Technology, Sathyamamgalam

638401, Tamilnadu, India.

ABSTRACT

Crumb rubber is a term usually used for recycles rubber removed from truck scrap and automotive tires. In this process the fluff and steel are removed, and the rubber is made in granular consistency using a granulator or cracker mill or with the aid of cryogenics or mechanical means. From this chemical and physical interaction of the crumb rubber, Crumb Rubber Modified Bitumen (CRMB) is made.

This asphalt rubber binder exhibits some disadvantages like high viscosity, segregation. Hence this is improved by using desulfurized rubber powder. The execution of desulfurized rubber powder with various rubber powder substance under different development time and shear conditions is assessed.

The practicality of modified asphalt bond quality test is finished with three distinctive pull out stubs. This test is done to test the loss of union and grip in asphalt bond quality because of dampness.

Index terms:

Asphalt rubber, Crumb Rubber Modified Bitumen, Desulfurized rubber powder, Bond strength test.INTRODUCTION

Nowadays, only a small amount of waste tyres is disposed. The recycled rubber is used in civil engineering applications, tyre-derived fuels, agricultural uses and other applications.

The use of modified rubber asphalts is being widely recognized and experienced and is likely to increase. This is made using a process called “wet process”. Since 1965s, this asphalt blends is being utilized throughout the world as an answer for various issues and improve the pavement execution.

This examination reports the consequences of existing advancements and determinations identified with the generation, handling and capacity of RTR-MBs and on their present applications inside street asphalt blends.

Performance of crumb rubber modified

bitumen by varying the size of crumb rubber

INTRODUCTION

The rheology of CRMB relies upon elements, type, amount, estimate, source, structure and outer factors, for example, temperature blending time, procedure of blending this examination is made by utilizing 15% of crumb rubber of four diverse size (1 mm - 600 μm); medium size (600 μm - 300 μm); fine (300 μm-150 μm); and superfine (150 μm - 75 μm). Basic laboratory tests are performed. And finally, a comparative study is made, and best size is determined obtain better results.

Experimental programs

Mixing of crumb rubber with plain bitumen

In the process of preparing modified binders, 500g of bitumen is heated to a fluid condition in a container. To mix crumb rubber, it is warmed to

160°C and is included of various sizes, which are coarse (1 mm - 600 μm); medium size (600 μm - 300 μm); fine (300 μm-150 μm); and superfine (150 μm - 75 μm). Then it is mixed manually for about 3-4 minutes and mechanically stirred for about 50 minutes. The bitumen is cooled in room temperature and stored for final test.

Preparation of Bituminous mix

For this study Bituminous concrete mix gradation was used following specifications stated by MORT & H table 500-19.

Three Marshall moulds and one loose mix is prepared for each size of crumb rubber. Aggregated used are oven dries and sieved based on BC gradation and separated. 1200gm as per gradation is weighed. The required height of specimen is 63.5(+/-1). Aggregate and bitumen are heated separately to 150 °C and 160 °C respectively. Then the bitumen is poured in aggregate as per the requirement a mixed thoroughly till it is uniformly coated on the aggregate and heated together around 170°C.

Grease is applied in the mould before placing the mix. Then the mould is assembled, and the mix is poured and compacted with 75 blows on either side of mould. The sample is extracted after 24 hours.

Marshall Stability tests

Before testing the dimensions, volume and weight in air, weight of dry SSD, weight in water of the moulds are noted. Then they kept in water bath for up to 20 – 30 minutes. The moulds are then tested within 3-4 minutes after taking out of the bath. The mould is kept on Marshall Apparatus and Marshall Stability, flow dial gauge readings are noted.

Density and air voids analysis

The bitumen content corresponds to 4% air void is taken as optimum bitumen content. With this OBC the Marshall test is done for four different sizes of crumb rubber. The results are noted and compared to find the best size of crumb rubber.

Table 1.1: Softening Point test results for CRMB of different crumb rubber sizes. Test Sample Sample Sample Sample

Property No.1 No.2 No.3 No.4

Penetration

(mm) 43.33 41.17 38.33 36.17

Advantages

Higher protection from twisting at hoisted asphalt temperature, higher weakness life of blends Lower powerlessness to temperature varieties, Better attachment between total and cover, age obstruction properties, Prevention of breaking and intelligent splitting, and Overall enhanced execution in outrageous climatic conditions and under substantial traffic condition.

Production and performance of desulfurized

rubber asphalt binder

Swelling principle of desulfurised rubber

asphalt

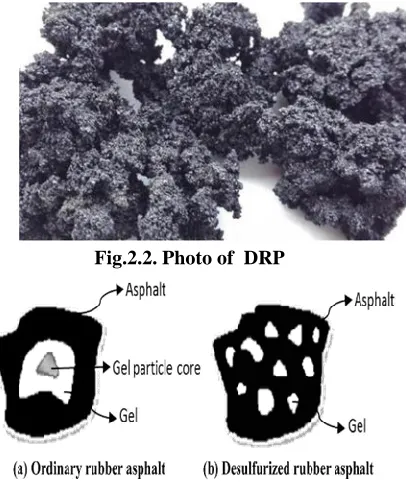

The swelling mechanism of asphalt rubber is depicted as pursues. The light oil in the base cover is consumed by the rubber particles, making the

rubber particles convert to a moderately free woolly structure from a thick structure, in this manner somewhat recuperates its un-vulcanized rubber property and consistency. Likewise, the diminished light the base binder results in an expansion in asphalt thickness. Asphalt rubber not just holds the fundamental mechanical properties of base cover, yet in addition halfway recuperates the versatility and thickness of rubber. In this way, contrasted and base cover, asphalt rubber binder has upgraded physical properties, strength, temperature affectability, and thickness.

swell method. Moreover, desulfurized elastic powder swells into the base spread, joined by a lot of air ascends, at a much faster rate than conventional rubber. At last, DRA binder dis-fathoms into the trichloroethylene at a slower rate contrasted with the tradition asphalt rubber cover. These perceptions demonstrate that substance responses happen between desulfurized rubber

powder and base cover with the end goal that the DRA binder yields preferable similarity and higher dependability over customary rubber. The DRA binder needs gel molecule centres when contrasted with standard rubber treated asphalt. This perception showed that desulfurized rubber powder more altogether swells into base cover than standard rubber treated asphalt.

Fig.2.2. Photo of DRP

Fig.2. 1. Swelling model of asphalt rubber.

Material and production

Process of desulfurised rubber asphalt

An unmodified binder, i.e., KLMY90# (Karamay) which are Saturated fraction 27.9%, aromatic fraction 31.7%, resin 39.6%, asphaltene 0.6% demonstrates the chemical constituents of the base binder. the desulfurized rubber powder, which gave a honeycomb structure roughly 6 mm in distance across. Its principle specialized and solvency test. The generation instruments for the

most part incorporate a high-speed shearing machine, electric coat, thermometer, and mixing pole. The fast shear machine has a speed scope of 0-12000 r/min and the electric coat consequently changes the temperature. In the DRA blend, desulfurized rubber powder is around 30 percent load of the base cover. Fundamental binder tests, for example, the entrance, mellowing point, and flexibility were led to assess the swelling effect of desulfurized rubber powder on the base binder.

Table 2.1: Main technical specifications of desulfurized rubber powder. Code

Test items Test value requirements

Carbon Black (%) 30 28 Metal content (%) 0.03 0.03 Fibre content (%) 0 1

Ductility is mostly about deformability of asphalt and in a roundabout way reflects low-temperature against breaking property. It is a vital record that can be utilized to assess asphalt

versatility to such an extent that the bigger flexibility esteems the better pliancy of the asphalt has. All these are the essential execution record to assess asphalt binder.

RESULTS AND DISCUSSION

Table 2.2: Solubility test results of different rubber modified asphalt Desulfurized Regular

Test items rubber asphalt rubber asphalt Rubber dissolution

rate (%) 70 40

E

ff

ects of shear rate and shear temperature

The shear rate and shear temperature were found to have immaterial effect on the needle infiltration. The 25 LC infiltration expanded when the shear rate was over 7000 r/min, however the addition was just 7.14%; there was no adjustment in 25 LC entrance when shear temperature expanded. The conditioning point and 5 LC pliability showed comparative changes as shear rate and temperature expanded. The conditioning point expanded with shear rate expanding from 3000 r/min to 5000 r/min and shear temperature expanding from 150 LC to 170 LC, and afterward it kept up a slight increment with shear rate expanding from 5000 r/min to 9000 r/min yet diminishing with shear temperature expanding from 170 LC to 190 LC. The 5 LC flexibility had a comparable assortment with relaxing point with the main distinction being the moderately little decrease as shear temperature expanded from 170 LC to 190 LC. The most extreme qualities in relaxing point and 5 LC pliability were accomplished when the shear temperature achieved 170 LC– 180 LC. Moreover, these outcomes shown that it was not evident that the higher shear rate and shear temperature the better DRA execution. To get ideal execution and monitoring vitality, this examination suggested the accompanying generation conditions: 9000 r/min

for consistence and pliancy, 7000 r/min for thickness at shear temperature of 170 LC.

E

ff

ects of shear time and development time

vitality, this examination suggested the accompanying generation conditions: 9000 r/min for consistence and pliancy, 7000 r/min for thickness at shear temperature of 170 LC.

E

ff

ects of desulfurized rubber powder content

The substance of desulfurized rubber powder clearly affected the blending effort and execution of resultant DRA covers. To get a suitable substance, cover tests were led on DRA binders with various substance (i.e., 10%, 20%, 30% and 40% by load of the base binder) of desulfurized rubber powder. In perspective on past testing results, shear rate, shear temperature, shear time and improvement time associated for evaluation in this section were 7000 r/min, 170 LC, 60 min and 45 min, individually. The essential binder testing results uncovered apparent relationships between the rubber powder substance and fundamental asphalt binder properties. The 25 LC entrance diminished with expanding of rubber substance, which demonstrated that the higher rubber substance the stiffer the resultant binder. In the rubber substance trial of this investigation, 25 LC infiltration achieved its base esteem 62.4 (0.1 mm) with substance of 40%. The difference in 5 LC malleability was inverse to that of 25 LC entrance, which showed that higher rubber substance brought about upgraded cover versatility. In this examination, 5 LC pliability achieved its greatest estimation of 14.8 cm with substance of 40%, yet once the substance was over 30%, the change rate started to diminish. The conditioning point expanded first, and afterward somewhat diminished. From the information, it very well may be concluded that the rubber asphalt binder had agreeable consistency with an rubber powder content scope of 30– 40%. The recuperation of versatility demonstrated a comparable pattern as the conditioning point; it achieved its most extreme esteem 57.5 LC with an rubber substance of 20– 40%.

Whatever, after a persistent expanding of the rotating thickness esteem at 175 LC with rubber substance from 10% to 30%, it had an undeniable 108.8% addition when the rubber substance expanded from 30% to 40%. Considering the discoveries, it was seen that there were great connections between different properties of DRA

container der and these properties can be evaluated from one another. In this manner, as per the field development application, cost contemplations and significantly more utilization of piece rubber, over 20% of rubber substance will reflect better asphalt rubber execution.

Execution of DRA binder

Super pave binder tests were led to explore the execution of DRA binders. The thickness of asphalt binder was researched by methods for Brookfield rotating consistency test. At that point dynamic shear rheometer (DSR) test and binding beam rheometer (BBR) test were performed in the lab to assess the high-temperature and low-temperature property of DRA. Similar tests were led to investigate the fundamental property, recuperation of flexibility, solidness, and hostile to maturing execution. The control asphalt binders‟ binders were KLMY90#, 20-mesh and 40-mesh

standard asphalt rubber binders.

Viscosity of asphalt binder

thickness diminished clearly. It showed that to improve asphalt binder thickness, higher temperature and pivot speed and longer time were not the best decision.

Like the creation procedure of DRA, an ideal range is should have been useful to handle development expert cesses and fulfil ecological concerns. In view of the investigation, it is recommended an ideal range for better consistency, shear time and advancement time of which are 45 to 60 min, shear rate is 4000 r/min to 7000 r/min, and shear temperature is 165 LC to 175 LC.

Performance of mixtures with DRA binders

Notwithstanding binder portrayal, blends with binders (AC-20 as the base cover) containing different substance of desulfurized rubber powder (0, 15%, 20% and 30%) were likewise planned and created. Fundamental blend tests were led, which incorporated the Marshall Stability test, Marshall Immersion test and Wheel Tracking test, to assess the effect of DRA binder on blend protection from perpetual misshaping and water harm. The Marshall Stability test is led to assess the obstruction of asphalt binder blends to twisting, relocation, rutting and shearing stresses. The soundness test estimates the most extreme burden supported by the example at a stacking rate of 50.8 mm/min. Fundamentally, the test load is expanded until it achieves a greatest, at that point the stacking is done, and the most extreme burden is recorded as Marshall strength. The Marshall Immersion test is directed after the AASHTO T 245. The effect of DRA blend on rutting opposition of asphalt binders‟ blends is assessed utilizing a Wheel-Tract Tester (WTT). The WTT highlights a mechanized information procurement framework and it reports the deliberate groove profundity at regular intervals.

Dynamic strength (DS), which can be determined from the deliberate groove profundity, is utilized as a fundamental record of trench obstruction for asphalt binder blends A feeble mix all around demonstrates a broad channel significance achieving a low DS regard, and then again, an immense DS regard can be ordinary from a strong mix with little score significance.

Extended substance of desulfurized elastic powder (up to 20%) achieved extended Immersion Stability, Residual Stability and Marshall Stability; in any case, these patterns were switched when over 20% desulfurized rubber powder was brought into the blends. A comparable pattern between rubber powder substance and dynamic strength was watched and the pinnacle estimation of dynamic steadiness happened at 25% rubber powder content. These discernments demonstrated the perfect substance extent of desulfurized elastic powder should be inside 20– 25%, which agreed with clasp testing results.

Using a modified asphalt bond strength test

to investigate the properties of asphalt

binders with poly ethylene wax-based warm

mix asphalt additive

Asphalt bond strength test method

ASTM-confirmed bond testing gadget, Posi Test AT-A programmed grip analyser, was utilized to play out the ABS test following the AASHTO TP 91-11 system. To set up the test examples, the asphalt binder is joined to the total surface by methods for grip at controlled ecological and dampness conditions. As indicated by AASHTO TP 91-11 strategy, every single total substrate was set up by cutting quarried rocks utilizing a standard shake saw to make parallel faces and after that Lapped utilizing a 280-coarseness silicon carbide material on a standard lapidary wheel to expel saw checks and guarantee a reliable surface unpleasantness. After cut and lapped, tests were cleaned for 60 min in ultrasonic cleaner containing refined water at a temperature of 60 LC to evacuate lingering particles on the plate surface. To gauge the draw off constrain expected to disengage the asphalt binder tests from the total sur-face, a water driven weight is connected to haul out a stub joined to the asphalt binder example.

outcomes utilizing just a single kind of gadget and one haul out stub of 0.8-mm thickness. Hence, for this investigation, three different altered haul out stubs with thicknesses of 0.8 mm, 0.4 mm and 0 mm (no edge) are proposed to be utilized with the Posi Test AT-A programmed attachment analyser. Limestone total and four different binder grades were tried utilizing the three hauls out stubs to discover which haul out stub ought to be utilized with the new grip testing gadget. Just un-moulded examples were tried in this piece of the investigation. by ideal asphalt binder substance of the blend. Asphalt binder binders were separated from field WMA blends from following three test segments.

To start with, the PE wax-based pellet (PE-Pellet) structure was connected to a 2.0-in factory and overlay WMA test area on the southbound outside path of TH 169 state parkway in Champlin, Minnesota. Asphalt binder cover PG64-28 and Granite total alongside 25% RAP by complete load of blend were utilized to set up the blend. Another HMA test segment was built for examination utilizing similar properties. The HMA and WMA blends were planned by Superpave blend structure strategy for a medium traffic dimension of 3– 10 million ESALs as indicated by Minnesota Department of Transportation (Mn ROAD) blend structure prerequisites.

Second, the PE wax-based fluid (PE-Liquid) structure was connected to a 3.0-in. asphalt binder layer on State Highway 158 in Lancaster, Ohio. The 3.0-in. layer comprised of middle of the road layer with a thickness of 1.75 in. furthermore, surface layer with a thickness of 1.25 in. WMA and HMA blends were planned by Marshall blend structure technique following Ohio Department of Transportation (ODOT) blend structure details for a medium traffic volume. The blend utilized a mix of Limestone and Natural rock totals and 25% RAP materials by load for the middle of the road layer and 20% RAP by load for the surface layer. Asphalt binder PG70-22 was utilized for the surface layer and PG64-22 was utilized for the middle layer. Just asphalt binder cover separated from the surface layer blends was assessed in this investigation.

Third, the uniquely structured PE wax- based fluid (SDPE-Liquid) structure for blends with high RAP sum was connected to a surface layer with a thickness of 1.5 in. on state thruway 6 in Iowa City, Iowa. Two WMA and HMA test areas were developed for a 10 million ESALs traffic volume. The blends were planned by Superpave blend structure strategy per Iowa Department of Transportation (Iowa DOT) blend plan necessities. The blends utilized asphalt binder binder PG64-28 and Limestone total alongside 30% fractionated RAP by cover substitution.

Modified asphalt bond strength test result

To catch the effect of different haul out stub thicknesses and the asphalt binder grade on the asphalt total bond quality, test examples utilizing four different asphalt binder grades; PG58-28, PG64-22, PG64-28M (polymer altered) and PG70-22M (polymer changed) were readied following AASHTO TP 91-11 test methodology. Asphalt examples, limestone total plates and haul out stubs were warmed up at 150L C for at least 30 min to expel assimilated water on the total surface and give a superior bond between the asphalt binder and the total surface. The total plates were then conveyed to an application temperature of 60L C, though the application temperature for the haul out stubs still 150L C. After a sufficient heat-up time, the liquid asphalt examples were cautiously poured in 10.0 mm measurement Dynamic Shear Rheometer (DSR) silicon forms and left for 30 min to achieve the room temperature. The asphalt examples were appended to the total plates by setting them on the outside of the haul out stub at that point immovably squeezing each stub with the asphalt example into the total plate surface until the stub is in contact with the total sur-face and no abundance of asphalt streaming is watched. The pre-pared tests were then left for 24 h at room temperature before testing.

The ABS test results with the numbers over each bar speaking to the normal esteem and the bristle speaking to the standard deviation. Covering of the standard deviations infers the comparability in the deliberate ABS esteems between the different sorts of haul out stubs. The 0.0 mm pull out stub delivered altogether higher

and more predictable ABS esteems than 0.4 mm and 0.8 mm stubs. The bond quality was fundamentally affected by the asphalt sort.

To quantify the genuine thickness of the connected asphalt layer, the total plates were cut over the inside line of the asphalt examples and examined utilizing Olympus SZ61 magnifying lens furnished with Olympus DP26 computerized camera The normal estimations of the asphalt layer for 0.8 mm, 0.4 mm and 0.0 mm haul out stubs were 998 lm, 539 lm and 106 lm, separately Asphalt layer thicknesses were estimated after the asphalt examples were presented to an immediate strain amid the test, which brought about a plastic twisting in the asphalt examples. As indicated by AASHTO TP 91-11, tests are considered flopped in attachment if over half of the cover is evacuated after the test is performed. Something else, the disappointment is durable. All the tried examples flopped in a firm mode aside from PG58-28 and PG64-22 asphalt examples tried with 0.0 mm haul out stubs. By taking a gander at the deliberate asphalt layers and the relating method of disappointment, tests with high asphalt layer thickness dependably bomb in firm mode. This clarifies why all the asphalt examples made utilizing 0.8 mm, and 0.4 mm stubs bombed in a durable mode. Then again, the asphalt examples made by 0.0 mm stub showed both durable and cement disappointment modes. The ABS esteems got from 0.0 mm haul out stubs were altogether higher than the others because there were more straightforward contact calls attention to the haul out stub and the total plate.

Rheology

and

adhesive

/cohesive

characteristics of extracted asphalt binders

The asphalt of mixes from the test separated were isolated, re-investigated and after that evaluated using the Multiple Stress Creep Recovery test following ASHTO TP70 Test of Asphalt Binder Using a Dynamic Shear Rheometer. The MSCR test utilizes the downer and recuperation strategy to quantify the percent recuperation and non-recoverable creep consistence. It tends to be utilized to anticipate the rutting defencelessness of the blend. Commonly, diminishing Jnr esteem considerably can lessen rutting significantly.

The changed ABS test utilizing the Posi Test Pull-Off attachment testing gadget and 0.0 mm (no edge) haul out stub was utilized to assess the asphalt total bond quality of the removed and recuperated asphalt binders in both wet and dry circumstances. As indicated by AASHTO TP91-11, the dampness conditioning process incorporates dousing the readied tests for 24 h in a warmed water shower at 40L ± 2 LC pursued by leaving for 1 h at room temperature before testing. The foreordained melding temperature by the AASHTO TP 91-11 framework can be changed to organize the melding temperature used for AASHTO T 283 or some other reasonable temperature as required Be that as it may, in this investigation, the conditioning temperature kept unaltered on the grounds that the examination concentrated primarily on the practicality of utilizing the current test methodology with another attachment testing gadget other than the one was initially utilized.

Rheological properties of the extracted

asphalt binder

The extraction process was done following the ASTM D2172/D2172M-11 and ASTM D5404/D540M-. After the extraction and recovery of asphalt binders was done, a full performance grading was done following AASHTO M 320 and AASHTO MP19-10.

The objective asphalt execution grade for Minnesota test segment with 25% RAP by weight of blend was 70– 22. In this way, because of the high RAP content, virgin asphalt evaluation was

brought by one dimension down to PG 64-28. The separated asphalt covers from both HMA and PE-Pellet blends of Minnesota test area were tried and evaluated as PG76-22 for a standard traffic ''S" level.

Asphalt binder PG70-22 was utilized for Ohio test segment with 20% RAP by weight of blend. The removed asphalt binders from both HMA and PE-Liquid blends of Ohio test segments were tried and reviewed as PG82-16 for a Stan the separated asphalt cover from the SDPE-Liquid blend was tried and evaluated as PG70-28 for an overwhelming traffic ''H" level. The SDPE-Liquid added substance diminished the effect of maturing on the asphalt folio amid development and improved the high and low temperature evaluations of the removed asphalt binder. Further, the SDPE-Liquid added substance upgraded the asphalt cover attributes amid the MSCR test by diminishing the non-recoverable jerk consistence, which brought about a higher qualified asphalt folio for a higher traffic level „„H” instead of a standard traffic level „„S” obtained for the extracted asphalt PG82-16 from the HMA mixture.

Asphalt bond strength test results

Overlapping of the standard deviation suggests the closeness in the deliberate ABS between the asphalt sorts. For both HMA and PE-Pellet tests from Minnesota test segment, dampness adapted examples displayed somewhat lower ABS esteems than the un-conditioned examples. Dampness conditioned PE-Pellet tests showed marginally lower ABS esteems than dampness adapted HMA tests. Dampness conditioned HMA and PE-Pellet tests from Minnesota test segment showed higher ABS esteems than tests from Iowa and Ohio test segments, which demonstrates a high protection from dampness harm

Dampness adapted HMA and SDPE-Liquid examples from Iowa test segment displayed essentially lower ABS esteems than un-conditioned examples. The dampness un-conditioned SDPE-Liquid examples showed essentially higher ABS esteems than HMA tests. Both HMA and SDPE-Liquid blends are defenceless to dampness harm. In any case, the SDPE-Liquid demonstrated a superior protection from dampness harm, which can be ascribed to the SDPE-Liquid added substance's capacity to enhance the rheological properties of the asphalt cover.

CONCLUSION

By concentrating the test aftereffects of basic research centre tests on plain bitumen and piece rubber changed bitumen it is presumed that the example arranged utilizing morsel rubber size (0.3-0.15mm) give the most noteworthy solidness estimation of 1597.64 kg, least stream esteem, greatest unit weight, greatest air voids and least VMA and VFB % qualities and best size to be utilized for scrap rubber adjustment can be recommended as size for business generation of CRMB.

After an extensive assessment of testing results, exhausted scopes of generation parameters are given: the shear and improvement time ought to be inside 35– 60 min, the shear rate ought to be inside 5000– 7000 r/min, and the shear temperature ought to be inside 155 C– 175 C. High substance of desulfurized rubber powder implies low asphalt substance, which possibly can decrease the grip between the total and the binder.

The ABS test can be directed utilizing another bond testing gadget with an adjusted 0.0 mm (no edge) haul out stub. The adjusted ABS test technique was effectively connected to assess extricated and recouped asphalt binders from three different test areas. Furthermore, it was discovered that the SDPE-fluid WMA added substance fundamentally enhanced both high and low temperature evaluations of asphalt. The MSCR test results demonstrated that the SDPE-fluid added substance essentially upgraded the non-recoverable jerk consistence and the percent recuperation of the asphalt binder. Moreover, the examples arranged utilizing the SDPE-fluid added substance displayed a superior dampness obstruction than HMA tests.

REFERENCES

[1]. "National Highways Development Project: An Overview" (PDF). Government of India. 7(1), 2014. [2]. Roadways (CIA Factbook)". CIA, United States. Retrieved 3, 2013.

[3]. The study of Souza and Weissman using a binder with15% rubber content (size of 0.2, 0.4 and 0.6mm) in dense- graded bitumen. 1994

[4]. Ministry of Road Transport & Highways (MORT&H), “Specifications for road and bridge works”. [5]. Mix design methods for asphalt concrete and other hot-mix types, asphalt institute manual series. NO2

(MS-2), 6.

[6]. S.K. Khanna and C.E.G Justo “highway engineering”2008.