COMPARISON STUDY ON

PERFORMANCE AND EMISSIONS

CHARACTERISTICS OF LPG AND

GASOLINE IN A TWO STROKE SI

ENGINE

V. GOPALAKRISHNANDepartment of Mechanical Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalainagar – 608 002. Tamil Nadu, India

gobu.krish.v@gmail.com M.LOGANATHAN

Department of Mechanical Engineering, Faculty of Engineering and Technology, Annamalai University, Annamalainagar – 608 002. Tamil Nadu, India

Abstract:

In this work a single cylinder two stroke three wheeler SI engine(199.3cc, 6.2 kW and 4500 rpm) was used for the test. The engine manifold was altered to run in LPG mode. The gas carburetor was used here to mix the air and LPG thoroughly. Initially the engine was operated with gasoline in carburetor mode for the constant speed of 3000 rpm at different load. Then the engine was operated with LPG mode at the same speed. The performance and emission parameters were compared with gasoline carburetion mode. The maximum brake thermal efficiency with LPG was 22.3% and that with gasoline was 20.3%. The engine could generally operate with lean mixtures with LPG due to its good mixture formation capability. The brake specific fuel consumption decreased for LPG compared to gasoline. The HC and CO levels were lower considerably at LPG mode compared to gasoline operation. High NO and exhaust gas temperature levels were the main problems with LPG.

Keywords: LPG; gasoline; S.I Engine.

1. Introduction

The ever-increasing energy demand is a prime concern of entire world. As gasoline prices sour and concerns over harmful emissions mount, vehicles which run on alternate fuel sources like LPG. The LPG is one of the most promising alternate fuels mainly because of its low exhaust emissions and better engine performance. Due to high fuel losses during the scavenging process the pollution emitted by these two stroke vehicles is significant.

It is well known that conventional carburetor two stroke engine have high exhaust emission and poor fuel efficiency. The advantages of LPG fuel have a higher content of hydrogen than gasoline and results a low emissions of HC and CO. The literature survey of some of the work done in LPG mode in petrol engines are given below.

report. The main benefits of LPG are that it yields 50% less CO, 40% less HC, 35% less NOx and has 50% less OFP (ozone forming potential) compared to gasoline. Holger Menrad et al [5]developed a LPG optimized vehicle and proved LPG’s best adaptation as a vehicle fuel. They have also studied the effect of various propane-butane ratios in LPG. They reported a reduction in CO and HC levels. But, a NOx emission is slightly higher in LPG vehicle. The lean limit was stretched up to 35 % without any suffering in the driving characteristics when LPG was used.

Lee et al. [6] compared the LPG development of internally comparable data on fuel consumption and exhaust emission. The hydrocarbon emission from the exhaust of LPG engine can be less than 13% of the minimum value obtainable with a gasoline fueled engine, LPG engines should have substantially no carbon monoxide in the exhaust and only 40-50% as much nitric oxide as a gasoline engine.

Baxter [7] obtained 70% less the LPG exhaust hydrocarbons reactive than those in gasoline exhaust. Oxides of nitrogen were significantly higher with LPG because of operation at maximum economy mixtures and maximum power spark advance.

Campbell et al [8] studied the LPG fuel burning rate, lean mixture limit, anti-knock performance and pollutant emissions and compared the lean limit of a homogeneous mixture of gasoline and LPG at gaseous phase. The results showed that the lean limit of LPG is better than gasoline.

Lai et al [9] the conventional LPG fueled vehicles can considerably reduce greenhouse gases (GHGs), particle mass (PM) as well as PN concentrations, and unregulated harmful emissions.

Adams et al [10]studied the effect of compression rations on a LPG fuelled vehicle. They have reported a 3.5 to 5 % reduction in peak brake power. Compared to gasoline, LPG reduced fuel consumption by 9-12 %. First they tested the engine at a compression ratio of 7.5. At this compression ratio, the LPG anti-knock values were for in excess. At a compression ratio of 11.5, they observed a 12 % increase in power output and 11 % decrease in specific fuel consumption. There was no need of spark advance for best torque. LPG antiknock quality needed to satisfy the engines at best power air fuel ratio and various ignition timings. Karim et al [11] did a review of the combustion characteristics of methane and propane as engine fuels for spark ignition and compression ignition engines. Results of comparative test involving spark ignition engines over a wide range of operating conditions were tested. Some of the performance characteristics considered were those relating to power output, brake thermal efficiency, tendency towards knock, cyclic variations, optimum spark requirements and exhaust emissions. Both of these fuels have in general performed well when compared to the gasoline. They have concluded that among these two fuels, methane has some excellent physical, chemical and combustion characteristics.

Khan et al [12] compared the exhaust emission of new European driving cycle between gasoline and LPG the results showed that the HC and CO emission of LPG is better than gasoline. Bayraktar et al [13] has developed and validated an engine simulator to compare performance and emission characteristics of an engine working on LPG and gasoline. LPG is a clean-burning fuel that can be used to internal combustion engines. LPG fueled vehicles produce fewer toxic and smog-forming air pollutants.LPG is usually less expensive than gasoline. From the literature it is concluded that the gaseous fuels still hold an advantage over liquid fuels. On the whole it is seen that LPG fuel reduces HC and CO emission, improvement in brake thermal efficiency in a two-stroke engine.

2. Present Work

In this work the two-stroke three-wheeler SI engine was modified to use LPG as the fuel. A gas carburetor in the form of a venturi was installed in place of the conventional gasoline carburetor. A special throttle body was made to house this venturi and other controls. A commercial LPG kit gas pressure, regulator and solenoid valve was used. LPG was supplied from a small cylinder that was placed on a precision weighing machine. The LPG cylinder was kept at constant temperature in a hot water bath to avoid reduction in temperature and hence in supply pressure as it vaporizes from the cylinder. A throttle with a potentiometric position sensor was used to regulate the flow of the LPG air mixture.

in the following graphs between the results obtained with gasoline and LPG under the power that gave the best brake thermal efficiency with LPG.

3. Experimental Setup

The experimental setup consists of a two stroke single cylinder SI engine (Make-TVS king) whose specifications are shown in Table.1 was connected to an eddy current dynamometer for loading. The fuel flow is measured using an electronic weighing machine. Air flow is measured by means of a turbine flow meter. In order to reduce the fluctuation of the incoming air, a surge tank is fitted. The engine lubrication was achieved by adding lubrication oil with inlet air stream.

Table 1. Engine Specifications

Type of engine Air cooled, single cylinder Two-stroke, S.I engine

Bore x Stroke 61 mm x 68.2 mm

Make TVS-king

Compression Ratio 7.7:1

Displacement volume 199.3cc

Power 3.4 @ 3000 rpm,

Mixture induction Reed valve Scavenging system Loop scavenging

An NDIR gas analyzer (Make: HORIBA, Japan) was used to measure exhaust gas emissions of HC, CO, and NOx concentrations. The schematic of the test setup is shown in Fig.1. The properties of gasoline and LPG are given in table.2

Fig. 1. Schematic of experimental setup.

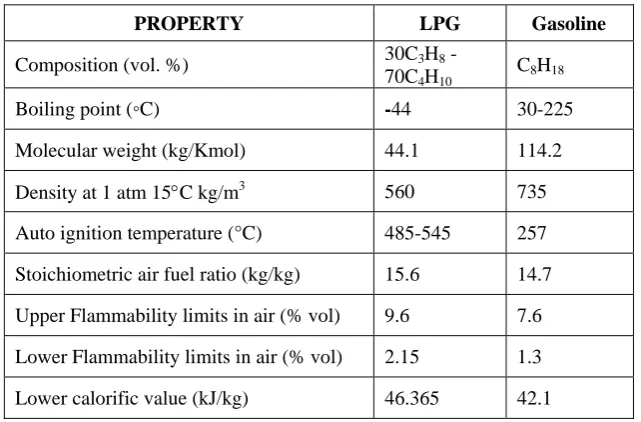

Table 2. Properties of LPG and gasoline

PROPERTY LPG Gasoline

Composition (vol. %) 30C3H8

-70C4H10 C8H18

Boiling point (◦C) -44 30-225

Molecular weight (kg/Kmol) 44.1 114.2

Density at 1 atm 15C kg/m3 560 735

Auto ignition temperature (°C) 485-545 257

Stoichiometric air fuel ratio (kg/kg) 15.6 14.7

Upper Flammability limits in air (% vol) 9.6 7.6

Lower Flammability limits in air (% vol) 2.15 1.3

Lower calorific value (kJ/kg) 46.365 42.1

4. Results and Discussion

Here the experimental results obtained under LPG operation of engine have been presented and compared with the gasoline operation mode.

Experiments were conducted at a constant speed of 3000 rpm at six throttle positions with LPG as the fuel. At each throttle position, changing the LPG flow rate through a manually adjustable control valve varied the air fuel ratio. The best air fuel ratio based on the brake thermal efficiency was obtained at each throttle condition and these results have been compared with gasoline operation.

From Fig. 2 It is found that the brake thermal efficiency increases for LPG mode as compared to gasoline. This is due to better mixing of LPG with air and improved combustion efficiency. In addition the calorific value of LPG is higher than the gasoline. The maximum brake thermal efficiency with gasoline is 20.3% at BP 2.6 kW and with LPG it is 22.3%

Fig. 3. Comparison of Air fuel ratio

The Fig.3 shows the variation of air fuel ratio with engine power for LPG and gasoline mode. In the case of gasoline the air fuel ratio is in the range of 12 to 14:1 where as it is in the range of 16:1 to 18.5:1 with LPG. It is confirmed that in LPG mode the engine is running in lean air fuel mode.

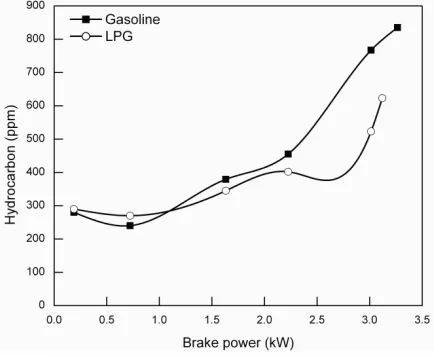

Fig. 4. Comparison of HC emissions

The HC emissions for LPG and gasoline operated mode are shown in fig.4. At low loads HC emission is higher for LPG compared gasoline. At full load the HC emission is 20% lower than gasoline. It is due to the mixture is vey learn and hence insufficient burning taking place. However at middle load and maximum load the HC emission is lower for LPG compared to gasoline. This is due to better air fuel mixture and hence better combustion taking place.

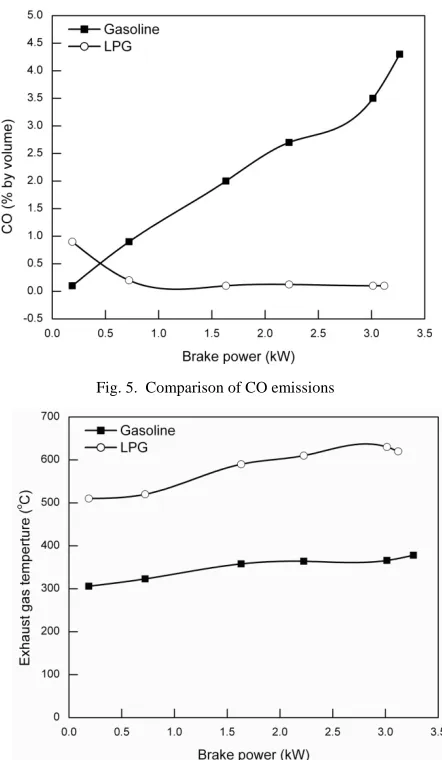

Fig. 5. Comparison of CO emissions

Fig. 6. Comparison of Exhaust gas temperature

Fig. 8. Comparison of Brake specific fuel consumption

The NO levels with LPG are always higher than gasoline carburetion due to the use of leaner mixture as shown in Fig 7. Further the temperature in the combustion chamber is higher due to absence of the cooling effect of the charge due to vaporization of the fuel in this case of LPG. At full load the NO level is 2010 ppm with LPG and 1515ppm for gasoline.

The Brake Specific fuel consumption is comparatively higher for gasoline than that of LPG as shown in Fig.8. This is due to better mixing of LPG with air results in more efficient burning process. At a full load the brake specific fuel consumption for LPG is 0.21 kg/kW-hr and gasoline is 0.43 kg/kW-hr. This is attributed mainly to increased thermal efficiency and higher calorific value of LPG.

5. Conclusion

The brake thermal efficiency is increased for LPG mode, compared to gasoline mode at middle load. Because the calorific value of Gasoline is (43MJ/Kg) less than the LPG (46.1MJ/Kg).

The air fuel ratio is higher for LPG, compared gasoline mode.

The NOx emission and exhaust temperatures are higher for LPG, compared to gasoline.

The reduction in the CO and HC levels were observed when LPG is used as a fuel. This reduction is due to the better combustion as well as the leaning of mixture.

The brake specific fuel consumption on LPG was lower than gasoline operated engine

On the whole it is concluded that the LPG has an advantages over gasoline for a two stroke spark ignition engines.

References

[1] Steve Seldlitz, “Converting a Gasoline Air -Cooled Engine to Propane,” SAE paper No.740746, 1974.

[2] Pourkhesalian AM, Shamekhi AH, Salimi F “Alternative fuel and gasoline in an SI engine: a comparative study of performance and emissions characteristics”, Fuel 2010; 89:1056-63.

[3] Stanley L.Genslak, “Evaluation of Gaseous Fuels for Automobiles,”SAE paper No.720125, 1972.

[4] Adam TW, Astorga C, Clairotte M, Duane M, Elsasser M, Krasenbrink A “Chemical analysis and ozone formation potential of exhaust from dual-fuel (LPG/gasoline) light duty vehicles”, Atmos Environ 2011; 45(17):2842-8.

[5] Holger Menrad, Rainer Wagener and Herald Loeck, “An LPG Optimized Engine- Vehicle Design,” SAE paper No. 852071, 1985. [6] Lee R.C and Wimmer D.B, “Exhaust emission abatement by fuel variations to produce lean combustion,” SAE paper No.680769,

1968.

[7] Baxter M.C, “Total Emission control possible with LPG vehicular,” SAE paper No.680529, 1968.

[8] Campbell M, Wyszynski L.P and Stone R “Combustion of LPG in a spark-ignition engine,” SAE paper 2004-01-0974.

[9] Lai CH, Chang CC, Wang CH, Shao M, Zhang YH, Wang JL, “ Emissions of liquefied petroleum gas from motor vehicles,” Atoms Environ 2009;43(7):1456-63.

[10] Adams W.E and Kenneth Boldt, “What Engines Say about propane fuel mixtures,” SAE paper No.640833, 1964.

[11] Karim G.A and Wierzba I, “Comparative studies of methane and propane as fuels for spark ignition and compression ignition engines,” SAE paper No.831196, 1983.

[12]Khan MA, Watson HC, Baker P, Liew G “SI Engine Lean-Limit Extension through LPG Throttle-Body injection for low CO2 and

NOx”,SAE paper No 2006-01-0495.