74

Available online at www.ijiere.com

International Journal of Innovative and Emerging

Research in Engineering

e-ISSN: 2394 – 3343 p-ISSN: 2394 – 5494

A Review on Study of Optimization of Operating Parameters

of Diesel Engine using Biodiesel

Chaitanya Godbole

1a, Karishma Chavan

2a, Pratik Deshmukh

3a, Pushkar Khasnis

4a,

Assit.Prof.Suryavanshi A.R

5babZeal College Of Engineering &Research 1, Narhe, Pune-411041,Maharashtra, India

ABSTRACT:

The motorization and the industrialization in the global market is increasing day by day. The demand of the petroleum products is increasing as well. This is the undesired phenomenon. There are only limited reserves of the conventional diesel minerals. These petroleum products are needed to be extracted from these reserves. This massive decrease causes the serious problem for the environment. Air pollution, global warming and green house crisis are the problems arising from these issues. It makes the use of alternative fuels important and makes us look for the same. Renewable energy sources are taken in the account. Hence, this paper completes the overall consideration of the schematic study of the reports about biodiesel engine performances with brake specific fuel consumption and specific fuel consumption. It includes optimization of the single cylinder four stroke diesel engine operating parameters and the performance using different software methods. The untouched areas where the optimization technique should be applied are concluded in the paper.

Keywords:Optimization technique, C.I. Engine performance, brake specific fuel consumption, specific fuel

consumption, Bio-diesel

I. INTRODUCTION

Bio diesel, a spectacularly divine form of the energy source and form of a fuel which is obtained from the vegetable oils, tree based oils, animals fat, waste cooking oils, etc. It is the best alternative form of the fuels other than the conventional fuels. The problems on the global radar such as, the depletion of the fossil fuels and the degradation of the environment are increasing in the apprehensive way.

The important and effective pollutants from C. I. Engines are hydrocarbons, carbon monoxide, Smoke levels and nitrogen oxides. The problem of rising requirements for efficiencies, high brake power and the fast depletion of the fuels demand total control on power and a fuel economy. So to overcome these problems the combustion of the motor engines and the overall use of the petroleum should be optimized. The optimization can be done with several methods which are overviewed in this review paper.

Biodiesel is the effective source for replacement of fossil fuel, which will decrease the necessity of procuring these oils at the expense of huge amount of money. Conventional resources are not everlasting so it is important to search for alternative fuel. Depletion of crude reserves, increasing prices of petroleum and the increasing demands of the efficiency have necessitated the replacement of the conventional sources with the alternative sources.

The factors taken into the consideration were the effective ones. The utilized blends required as fuels in an operational C. I. Engine were B10, B20, B30 and the neat diesel. The biodiesel to be selected (moringa oil) cannot be used entirely and necessarily needed to be added to the diesel count. The blend contains specific amount of the biodiesel which varies the efficiency, performance and exhaust emissions status of the single cylinder four strokes C. I. Engine. So does the compression ratio. The variation in the CR factorizes the optimization process.

Load alterations vary the performance as well.

75 II. LITERATURE REVIEW

K. Sivaramakrishnan et al[1], studied that the combustion of fossil fuels produces large amount of emission, so to reduce this emission biodiesel are the best alternatives instead of diesel oil. Since they are renewable and have similar properties. In this paper biodiesel (10, 20, 30, and 50 %) blended fuel, different compression ratios (17.5, 17.7, 17.9 and 18.1), and power (3.64, 4.16, 4.68, 5.2) were used as input parameter, whereas brake specific fuel consumption, brake thermal efficiency, carbon monoxide, hydrocarbon and nitrogen oxides are the response parameter. A compression ratio 17.9, 10 % of fuel blend and 3.81 kW of power could be considered as the optimum parameters for the test engine. Vegetable oils or biodiesel are the same power output, with slightly lower thermal efficiency when used in diesel engines. Biodiesel such as Jatropha, Mahua, Palm Oil, Karanja, sunflower, and rapeseed are some of the popular biodiesel currently considered as substitutes for diesel. These are clean burning, renewable, non-toxic, biodegradable, and also environmentally friendly transportation fuels as compared to diesel oil. It is clear from this research that CO and HC emissions have been reduced when biodiesel is fueled instead of diesel. Advancing the CR from 17.5 to 18.1 helped to decrease the CO and HC emissions. Decreasing the fuel blend ratios contributed for better BTHE with lesser BSFC with lower CO, HC and NOx values. However, when too low was the blend ratio, the results were good. The maximum BTHE for B10 (35.42 %) was higher than that of diesel at full load.. A high desirability of 0.97 was obtained at the optimum engine parameters of CR of 17.9, fuel blend B10, and 3.81 kW power, where the values of the BTHE, BSFC, CO, HC, and NOx were found to be 33.65 %, 0.2718 kg/kW-1 h-1, 0.109 %, 158, and 938 ppm, respectively.

A. K. Azad [2], found that Moringa oleifera is the crop which is cultivated in any areas. It contains 6 to10 seeds. The well developed seeds of moringa contain 38 - 40% vegetable oil which are colourless and 25-30% of moister. It requires rainfall about 250-2000 mm depending on soil condition. It grows best in dry sandy soil .The height range of the moringa tree is of 10-12 mand the main stem diameter of tree is of 30-45 cm. A good tree can yield 1000 pods or more. Transesterification method is used to produce the biodiesel. The flashpoint temperature of the moringa oil is 162ºC. This value is higher than the minimum requirements. The high flash point temperature is useful for safety purpose, as this fuel can safely be stored at room temperature. When moringa biodiesel is used instead of pure diesel, the brake power decreases, brake specific fuel consumption slightly increases and brake thermal efficiency goes down. Only the emission of NOx is Increases and other emissions such as CO, CO2, PM and HC are decreased..

Dhruv V. Patel [3], stated that according to statistical review of world energy published by British Petroleum the increase of oil reserves in world from 2012 to 2013 is 0.60% whereas oil consumption increases from 2012 to 2013 is 1.40%. Due to the increasing take care of fossil fuels and environmental issues, biodiesel are more used in recent years. In this experimental study has been carried out for Jatropha biodiesel blended with diesel used in single cylinder diesel engine. Consumption of diesel fuel is reduced when jatropha biodiesel is blended with diesel engine with high proportion. In this study, the input parameter are taken as blends, load and compression ratio for optimize the diesel engine parameter. The results of the taguchi experiment identifies that 0% blend ratio, compression ratio 18 and engine load 10kg are optimum parameter setting for lowest bsfc. Blending means to form the biodiesel by using the diesel and vegetable oil. We used 50% blend and pure biodiesel. A method called ‘Taguchi’ was used in the experiment for simultaneous optimization of engine such as compression ratio, blend composition and load condition. The taguchi method is the simplest method of optimization. Engine load is greatly affected and compression ratio are least affected on engine performance.

Salem et al.[4] (1998) had investigated the effect of different injection pressures, injection advance angles and different fuel-hole diameter (orifice) on the NOx emissions. In this analysis it was concluded that reducing the NOx emission level without noticeable loss of power was achieved by related adjustment of injection parameters. Injection timing, injection pressure, intake gas temperature, engine speed and load were taken as parameters for the optimization study. The effect of the above parameters – injection pressure, fuel injection timing, intake gas temperature and engine speed on NOx emissions and smoke were investigated and a strong correlation between the injection timing and NOx emissions was reported. An increase in an injection pressure leads to fuel economy by improved mixing. Simultaneous reduction of NOx and particulate emissions were reported by combining the retarded injection timing and EGA. Optimal combination of design and operating parameters was identified, which regulate the emissions and improve brake specific fuel consumption. For identifying the optimal combination of injection timing and fuel spray cone angle. Genetic algorithm process was used. The effect of changes in the operating parameters like nozzle spray holes, piston to head clearance, nozzle protrusion, injection pressure, start of injection timing and swirl level on emissions were studied using Taguchi design of experiment methods. This method was found to be useful for simultaneous optimization.

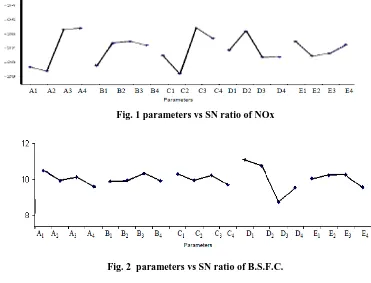

76 Vincent H.wilson and udayakumar [6] (2010) had optimized the control parameters of the direct injection (DI) single cylinder diesel engine with respect to NOx (Oxides of Nitrogen) and fuel emissions through experimental investigations and Taguchi method. Five parameters such as clearance volume, valve opening pressure, nozzle-hole diameter, static injection timing and load torque were varied at four levels and the responses such as NOx emissions and fuel economy were recorded. The optimum values of the response variables were predicted using S/N ratio and optimum combination of control parameters were specified. Thus the relationship between the diesel engine operating parameters with NOx and b.s.f.c (brake specific fuel consumption) were understood using Taguchi method of experimental design.

Fig. 1 parameters vs SN ratio of NOx

Fig. 2 parameters vs SN ratio of B.S.F.C.

Table 1. Analysis of variance for NOx emissions

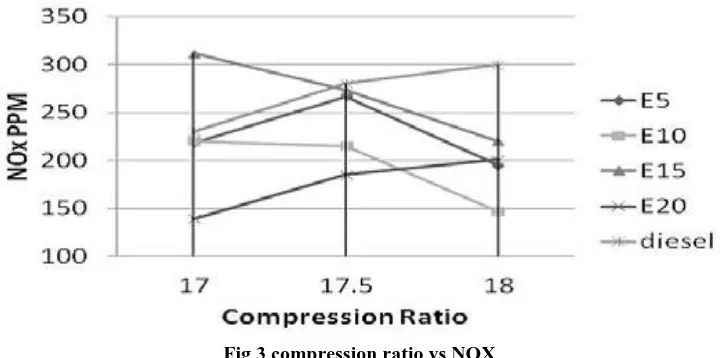

77 Santosh Kumar Kurre, Shyam Pandey, Mukesh Saxena [7] had analyzed that, Effect of Compression Ratio on Diesel Engine Performance and Emission with Diesel Ethanol Blends.

Their work was performed on a 3.7kW, 4 –stroke single cylinder, water cooled, variable compression ratio, diesel engine fueled with the different blends of ethanol and diesel fuel on three different compression ratios of 17, 17.5 and 18. When the percentage of ethanol increases with increase in the blend of HC . Smoke reduces as compression ratio increase. When compared with diesel fuel the smoke increases for all blends for lower CR while for higher CR smoke reduces drastically. As compression ratio increases the NOx increases for neat diesel while NOx decreases for lower blends .CO was not changed with compression ratio for all the blend of fuel. Brake specific fuel consumption decreases with the compression ratio increases. Brake thermal efficiency increase with the compression ratio for all fuel. Exhaust gas temperature increases with compression ratio for all blends.

Fig 3 compression ratio vs NOX

Maulik A Modi, Tushar M Patel , Gaurav P Rathod [8] studied Parametric Optimization Of Single Cylinder Diesel Engine For Moringa Oil & Diesel Blend For Brake Thermal Efficiency Using Taguchi Method. In this study, the effects of parameters i.e. load, compression ratio and injection pressure are taken as variable for optimization. As the experiment required simultaneously optimization of three parameters with three levels, Taguchi method is used.

Tamilvendhan D [3], Biodiesel possesses low cetane number and high viscocity which is not sufficient to operate existing diesel engine. However, this could be admissible along with diesel fuel in the form of blends. It involves three parameters such as blend proportion, injection timing and injection pressure, as a input parameter.Brake thermal efficiency and combustion, emission are the response parameter. The results showed that the mixing of Eucalyptus oil with diesel fuel up to 40% increases brake thermal efficiency by 2.5% from the reference fuel; Taguchi method of optimisation predicted optimum level of parameters within 9 trials and the 40Eu blend found working satisfactorily at optimum setting; Comparatively a slighter increment in NOx emission was found while working with 40Eu blend at optimum setting; Approximately 50% smoke reduction was achieved with 40Eu operation; and A smaller on shoot of CO was found with 40Eu operation at full load. The results also proved that the blending of Eucalyptus oil with diesel fuel up to 40% increases the engine performance without much worsening its emission. Taguchi method is a simplest method of optimising experimental parameters in less number of trials. The number of parameters involved in the experiment determines the number of trials required for the experiment. More number of parameters led to more number of trials and consumes more time to complete the experiment. The taguchi method used in the investigation was designed by statistical software called ‘Minitab Release 15’ to simplify the taguchi procedure and results.

III. CONCLUSIONS

78 REFERENCES

[1] K. Sivaramakrishnan “Optimization of operational parameters on performance and emissions of a diesel engine using biodiesel” Int. J. Environ. Sci. Technol. (2014).

[2] A. K. Azad ‘Prospect of Moringa seed oil as a sustainable biodiesel fuel in Australia: A review” 6th BSME International Conference on Thermal Engineering (ICTE 2014).

[3] Dhruv V. Patel “Parametric Optimization of Single Cylinder Diesel Engine for Jatropha Biodiesel and Diesel Blend for Brake Specific Fuel Consumption Using Taguchi Method” Volume 12, Issue 2 Ver. VI (Mar - Apr. 2015).

[4] Maulik A Modi, Tushar M Patel , Gaurav P Rathod, ‘Parametric Optimization Of Single Cylinder Diesel Engine For Palm Seed Oil & Diesel Blend For Brake Thermal Efficiency Using Taguchi Method’, ISSN (e): 2250-3021, ISSN (p): 2278-8719 Vol. 04, Issue 05 (May. 2014), ||V5|| PP 49-54

[5] Vincent H. Wilson, Udayakumar,’ Optimization of Diesel Engine Parameters Using Taguchi Method and Design of Evolution’, J. of the Braz. Soc. of Mech. Sci. & Eng. Copyright Ó 2012 by ABCM October-December 2012, Vol. XXXIV, No. 4’