Full Length Research Paper

Effect of aggregate size and proportion on strength

properties of palm kernel shell concrete

U. Johnson Alengaram*, Hilmi Mahmud, Mohd Zamin Jumaat and S. M. Shirazi

Department of Civil Engineering, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia.

Accepted 31 August, 2010

This paper presents information on the physical and mechanical properties of different sizes of palm kernel shells (PKS) used here as lightweight aggregates (LWA) and their influence on mechanical properties of palm kernel shell concrete (PKSC). Silica fume and fly ash were used as cementitious materials and all mixes had 1% superplasticizer on cement weight. It has been found that PKS consists of about 65 to 70% of medium size particles in the range of 5 to 10 mm. The other two sizes, namely, small (0-5 mm) and large (10-15 mm) sizes were found to influence the mechanical properties of PKSC. The 28-day compressive strengths were found in the range of 21 to 26 MPa. The concrete mix that was made with medium size PKS only produced lower compressive strength of about 11% compared to the mix that contained all sizes of PKS. However, the exclusion of medium size particles didn’t cause any segregation in the gap-graded aggregate concrete. The strength of PKS and bond governed the failure of PKSC. The flexural and splitting tensile strengths were found respectively 12 and 7% of the compressive strength. PKSC with about 70% of PKS of large size produced the highest modulus of elasticity of about 11 GPa.

Key words: Palm kernel shells, fly ash, silica fume, mechanical properties.

INTRODUCTION

Palm kernel shells (PKS) or oil palm shells (OPS) are organic waste materials obtained from crude palm oil producing factories in Asia and Africa. In recent years, many research works on the use of palm kernel shells (PKS) as lightweight aggregate (LWA) to produce lightweight aggregate concrete (LWAC) have been carried out (Abdullah, 1984; Okafor, 1988; Mannan and Ganapathy, 2002; Mannan et al., 2004; Olanipekun et al., 2006; Alengaram et al., 2008; Mahmud et al., 2009; Jumaat et al, 2009). Most of the above researchers used PKS of all sizes after removing the dust and fibres. The maximum size of PKS is found about 15 mm. Though the sizes of PKS may vary depending upon the type of machinery used to crack the palm nuts, generally the size of the shells are in the range of 2 to 15 mm. The shells are flaky, parabolic, angular, and posses smooth concave

*Corresponding author. E-mail: ujohnrose@yahoo.com. Tel: +603 7967 7632. Fax: +6 03 7967 5318.

and convex surfaces. The thicknesses of PKS vary in the range of 1.5 - 3 mm. Past research works carried out on PKS focussed on using the shells of different sizes above 3 mm after removing smaller particles less than 3 mm. The results showed that using PKS as LWA, structural grade concrete of compressive strength of about 15 to 25 MPa could be produced (Mannan et al., 2002). Generally, the strength properties of LWAC are influenced by aggregate parameters such as size, shape, roughness and stiffness. In addition, the LWA-cement matrix bond plays a very important role in strength development (FIP Manual, 1983).

Table 1. Chemical composition of cement, fly ash and silica fume.

Oxide composition (%) Materials

SiO2 Al2O3 Fe2O3 CaO MgO SO3 K2O Na2O LOI TiO2 P2O5

Cement 19.8 5.10 3.10 63.4 2.50 2.40 1.00 0.19 1.80 NA NA

Fly ash 64.6 20.9 4.00 1.00 0.66 0.30 1.20 0.32 5.10 1.10 0.07 Silica fume 94.6 0.14 0.11 0.01 0.01 0.01 0.62 0.01 4.10 0.01 0.22

al. (2008a) and Teo et al. (2006), respectively. They reported that the performance of PKSC was superior with respect to ductility. Later, Jumaat et al. (2009) reported shear behaviour of palm kernel shell foamed concrete and found out that aggregate interlock behaviour of PKS contributes significantly to shear strength.

In the past research works, all sizes of PKS have been used as a complete or as a partial replacement for gravel aggregates. However, there are no literatures available on the physical and mechanical properties of different sizes of PKS and their influence on mechanical properties of PKSC. It has been reported by the researchers (Okafor, 1988; Mannan et al., 2002; Jumaat et al., 2009) that a poor bond between the PKS and the cement matrix resulted in bond failure. This contributed to lower mechanical properties in PKSC. The bond failure may be attributed to the smooth and convex surface of PKS (Mahmud et al., 2009). Silica fume (SF) has the ability to localize at the surface of the aggregates (Neville, 1995) to enhance the bond between an aggregate and the cement matrix. The extremely fine SF particles react with liberated calcium hydroxide to produce calcium silicate and aluminate hydrates in concrete. These increase strength and reduce permeability by making the matrix of the concrete more dense (Robert et al., 2003). Thus, the zone between the aggregate and the cement paste interface, which is called the zone of weakness, is strengthened.

The objective of the work described herein was to provide some basic information on the properties of different sizes of PKS and their influence on mechanical properties of PKSC. The PKS obtained from factory have been sieved, grouped under different sizes and concrete mixes were prepared. In all the concrete mixes, 5% fly ash (FA) as cement replacement and 10% of silica fume (SF) as additional cementitious material, both on weight of cement have been incorporated. The effect of different particle sizes on workability and compressive strength under four different curing regimes has been investigated and reported. Its effect on other mechanical properties such as flexural and splitting tensile strengths and elastic modulus is also reported.

EXPERIMENTAL WORKS

Materials and mix details

Ordinary Portland cement (OPC) that confirms to MS 522: Part-

1:2003 was used (MS 522, 2003). Class F fly ash and SF supplied by Lafarge Malayan cement and ELKEM materials, respectively were used as cementitious materials. The chemical composition of OPC, FA and SF are shown in Table 1. Mining sand with specific gravity and fineness modulus of 2.7 and 2.81 respectively was used as fine aggregate. The PKS obtained from the factory were washed, dried and divided into three groups, namely small (0 to 5 mm), medium (5 to10 mm) and large (10 to15 mm). The diverse sizes of PKS are shown in Figure 1. The water to binder (w/b), sand to cement (s/c) and aggregate to cement (a/c) ratios for all the mixes were kept at 0.35, 1.0 and 0.8, respectively. The binder content includes FA and SF in addition to cement. All mixes had 1% of naphthalene based superplasticizer by weight of cement.

Table 2 shows details of five concrete mixes that were prepared using different sizes and proportions of PKS to study the effect of size and proportions. The samples were cured in different curing conditions as detailed in Table 3. The specimens prepared include 100 mm cubes for compression test, 150 mm x 300 mm diameter specimens for modulus of elasticity and splitting tensile tests and prisms of 100 x 100 x 500 mm size for flexural tensile tests. The specimens prepared include 100 mm cubes for compression test, 150 mm x 300 mm diameter specimens for modulus of elasticity and splitting tensile tests and prisms of 100 x 100 x 500 mm size for flexural tensile tests. The cement content for all mixes was about 550 kg/m3. Firstly, the PKS and sand were added in the mixer,

followed by cement and cementitious materials. Water and superplasticizer were then added and the mixing was done for about 5 min.

The fresh density of the concrete was measured immediately after mixing (ASTM C 138, 2003). After demoulding at 24 h, the specimens were cured in four curing environments as specified in Table 3. The samples were wrapped in two layers of plastic film on demoulding and stored in a controlled environment for samples cured under P1 type of curing. For P2 type cured samples, on demoulding, the samples were cured in water for 6 days and then wrapped in plastic film. Then both P1 and P2 type cured samples were stored in sealed conditions at 23º C and at a relative humidity of 60 ± 5 % until the day of testing.

Testing

a) PKS of all sizes b) PKS of 2.36 to 5 mm sizes

c)PKS of size between 5 to 10 mm d) PKS of size 10 mm and above

[image:3.612.139.480.72.302.2]Figure 1. Palm kernel shells of different sizes.

Table 2. Aggregate proportion, fresh concrete properties and densities.

Mix description Aggregate size (mm) and proportion∗∗∗∗ (%)

A1 2 -15 (100)

A2 2 -10 (100)

A3 5 -10 (100)

A4 5 -10 (60) : 10 -15 (40)

A5 0 -5 (30) :10 -15 (70)

[image:3.612.169.451.379.464.2]∗ Proportion in percentages is given in brackets.

Table 3. Curing environment (26°C).

Symbol Mould (days) Water (days) Room∗∗∗∗ (days) Uncontrolled environment (Days)

W 1 364 - -

P1 1 - 364 -

P2 1 6 358 -

AC 1 - - 364

∗Temperature: 23°C and Relative humidity: 60 ± 5%.

water cured specimens.

DISCUSSION OF EXPERIMENTAL RESULTS

Physical and mechanical properties of PKS

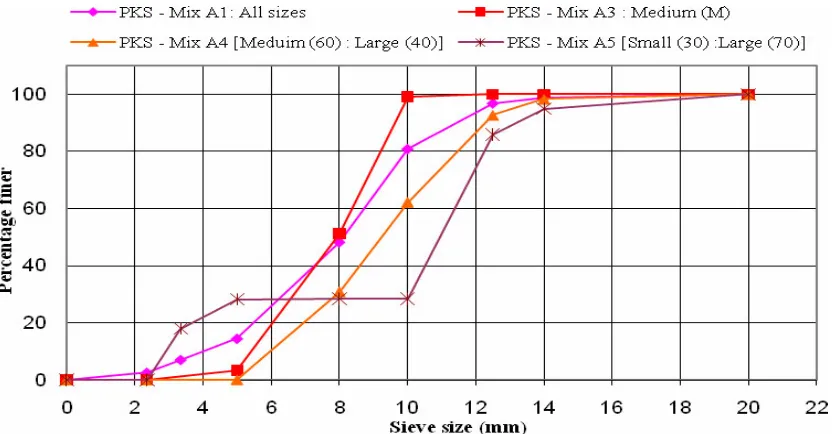

Figure 2 shows particle size distributions of PKS of different proportions. It can be seen that for PKS of

all sizes, about 65 to 70% of the particles is of medium size (M) that vary between 5 to 10 mm in size. The medium sized particles are flaky and angular; some of the bigger particles are parabolic with convex and concave surfaces. About 15 to 20% is above 10 mm size, classified here as large size (B) and mostly these particles have smooth convex and concave surfaces.

[image:3.612.87.537.524.590.2]Figure 2. Particle size analyses of palm kernel shells of different sizes.

Table 4. Aggregate proportion, fresh concrete properties and densities.

Aggregate sizes (mm)

Properties 0-5

(Small-S) (Medium-M) 5-10 (Large-B) 10-15 5 -15 2-10

Dry loose bulk density (kg/m3) 565 569 542 566 562

Dry compacted bulk density (kg/m3) 644 639 608 651 646

Relative density (saturated surface dry) 1.42 1.38 1.35 1.37 1.39

Fineness modulus - 6.10 6.97 6.39 5.97

Aggregate impact value (%) 15.4 3.51 2.45 3.91 4.50

Aggregate abrasion value, Los Angeles (%) - 8.42 5.58 8.02 8.85

1-h water absorption (%) 14.38 9.49 8.56 9.14 8.42

24-h water absorption (%) 24.86 22.38 22.69 22.59 21.8

rounded and angular. Thus, most of the particles of PKS obtained from palm crude oil producing plants are of medium size. Also, the curve for PKS: Mix A1 shows that about 50% of particles are above 8 mm. The curve PKS: Mix A3 shows that for medium size particles, the distribution is narrow. The particle size distribution curves for particles combined in different proportions for mixes A4 and A5 are shown in curves PKS: Mix A4 and A5. Table 4 shows the test results of physical and mechanical properties of PKS of different sizes. The relative densities of different sizes were found to vary between 1.35 and 1.42. The smaller particles (S) have higher relative density compared to other sizes. The higher water absorption of smaller size particles compared to other sizes may be attributed to large number of pores in the small particles. The bulk densities, fineness moduli, Los Angeles abrasion and aggregate impact values (AIV) of

different sizes are given in Table 4. The AIV of smaller particles is nearly 50% higher compared to other particles and this is due to brittle nature as they are scales from the larger particles. And hence these smaller particles get crushed due to impact compared to larger particle. The lower impact and abrasion values obtained for particles of size 10 mm and above show that they are harder and tougher than other sizes.

Density and fresh concrete properties

Table 5. Fresh concrete properties.

Cured density (kg/m3)

(as on 28 days) Workability (mm)

Mix designation Fresh density (kg/m3)

W P1 P2 AC

Oven dry density

(kg/m3)

Slump Flow

A1 1721 1750 1690 1710 1671 1525 90 220-400

A2 1790 1810 1727 1737 1685 1597 120 220-410

A3 1763 1775 1680 1700 1680 1572 80 210-360

A4 1759 1774 1667 1680 1660 1544 50 200-300

A5 1703 1735 1690 1728 1653 1525 90 200-380

Figure 3. Development of compressive strength of mix A1.

1790 kg/m3. The lower fresh densities of the mixes may be attributed to low fine aggregate content that has higher relative density than PKS. The lowest fresh density obtained for mix A5 may be due to more voids created as large size particles produce low compacted bulk density.

The air and oven dry densities were 50 to 100 and 175 to 215 kg/m3 respectively lower than the fresh densities. If air dry density is taken into consideration in design, then there is a reduction of about 25 to 30% in dead load compared to NWC. The densities of P1 and P2 cured samples were 1 to 5% lesser than the fresh densities. As can be seen from Table 5, all concrete mixes produced high workability, except the mix A4 that produced medium workability. It can be seen from the results that mix A2 that contained particles of sizes 2 to10 mm has the highest slump of about 120 mm. Abang (1984) reported that the workability of PKS concrete is influenced by proportion of PKS used, w/c ratio and sand content; higher proportion of PKS content reduces the workability and compressive strength. The mix A4 containing 60% of medium and 40% of bigger particles

produced the lowest slump of about 50 mm. However, the mix A5 with 70% proportion of particles above 10 mm and 30% of particles less than 5 mm produced high workability. Thus, it can be concluded that in mix A4 the absence of smaller particles that are rounded in shape produced inadequate compaction that reduced workabi-lity. The gap-graded aggregates in mix A5 didn’t cause segregation as generally happen in the case of normal weight concrete. It was evident that the addition of silica fume produced cohesive mix that prevented segregation. The flow table tests showed that the concrete mixes were uniform and cohesive and the flow values ranged between 200 to 410 mm as given in Table 5. It can be concluded that different sizes and proportions of PKS didn’t cause much variation in workability.

Compressive strength

Figure 4. Development of compressive strength of mix A2.

Figure 5. Development of compressive strength of mix A3.

Figure 7. Development of compressive strength of mix A5.

28-day strength of water cured specimen of about 26 MPa was achieved for mix A1 that contained all ranges of particles. The 7-day strength showed high early strength of about 90% on 28-day strengths. This may be attributed to the high reactivity of SF and its micro filler effect (Malhotra, 1992; Neville, 1995). However later hydration due to the addition of 5% of fly ash was not evident even in water cured specimen.

There was strength gain of about 1 to 6% between 28 and 90 days on 28-day strength for specimens cured in W and P2 curing environments. The P1 cured specimens haven’t shown strength gain between 90 days and 1 year. During the same period for water stored and P2 cured specimens, a slight increase in strength of about 1 to 3% on 90 day strength has been noticed. Since 90% of strength is achieved in 7 days, the P2 cured specimen produced strengths similar to that of water stored specimens. In most of the cases, P2 cured specimens have matched the strength of water cured specimens. However, retrogression in P1 cured specimen strength of about 2 to 4% on 90 day strength was noticed between 90 and 365 days. The ratio between 28 day strength of air and water cured specimens is in the range of 83 to 92%. Between 28 and 365 days, the air cured specimens have shown retrogression of strength of about 3 to 7%.

Particle size effect on compressive strength

Figure 3 shows the development of compressive strength of mix A1 that has been prepared using PKS of all sizes ranging from 2 to 15 mm. The strengths of other mixes are compared against the mix A1 as it contained all sizes as obtained from factory. The mixes A1 and A2 that contained particle sizes with continuous grading

produced similar strength gain. The exclusion of larger particles of sizes more than 10 mm in mix A2 didn’t seem to cause much variation in compressive strength. However, a comparison of Figures 3 and 5 shows that the mix A3 that contained only medium size particles produced about 11% lower on 28-day water cured compressive strength than mix A1. Thus it can be concluded that the exclusion of particles less than 5 mm and larger than 10 mm had influenced the strength. The particles less than 5 mm that amounts to 10 to 15% of total weight have higher particle density, and these smaller particles pack the voids and influence the strength. The compression failure of specimens of mixes A1 to A4 was governed by the strength of PKS as indicated by the examination of the broken cubes.

Table 6. Splitting tensile, modulus of rupture and static modulus of elasticity of PKSC.

Splitting tensile strength (MPa) Modulus of rupture (MPa) Static modulus of elasticity (GPa)

Mix no

28-day 56-day 90-day 28-day 56-day 90-day 28-day 56-day 90-day

A1 1.80 1.86 1.92 2.96 3.12 3.20 7.63 7.68 7.72

A2 1.84 1.86 1.91 3.00 3.17 3.21 8.80 8.84 8.90

A3 1.71 1.76 1.80 2.81 2.86 3.02 7.24 7.35 7.98

A4 1.50 1.53 1.55 2.51 2.63 2.65 7.01 7.04 7.15

A5 1.64 1.67 1.74 2.21 2.38 2.42 11.18 12.00 12.31

addition to fracture of PKS, the bond failure occurred between these large size particles and cement matrix. The bond failure was evident in most of the specimens along the smooth convex surfaces of larger particles. Thus it can be concluded that the compression failure of specimens of mix A5 is governed by both the strength of PKS and bond between PKS and cement matrix.

Tensile strength

Table 6 shows the splitting tensile, flexural strengths and modulus of elasticity of concrete of water cured specimens measured at 28-, 56-, and 90 days. The trends of the tensile strengths are similar to those for compressive strength. The mixes A1 and A2 produced the highest tensile 28-day flexural strengths of about 3 MPa. However the mixes A4 and A5 produced lower strengths, which may be attributed to the factors already discussed. The failure of the flexural and splitting tensile specimens is governed by both the strength of PKS and bond between PKS and cement matrix. The ratio of 28-day splitting tensile strength to respective compressive strength is about 7% for all mixes, and the corresponding ratio for flexural strength, was about 12%. The Building Research Station (Short and Kinniburgh, 1978) gives the following relationship for LWAC between cylinder splitting strengths to cube strengths:

fct = K fc1/2 (1)

Where K is a factor varies from 0.37 - 0.5; fct and fc are splitting tensile strength and cube compressive strength respectively in MPa.

The results obtained from the tests for mixes A1 to A3 are closer to the tensile strengths obtained using a value of K = 0.37 in equation (1). However, the results for mixes A4 and A5 are lower than the values obtained by equation (1) by about 12 and 8% respectively. Overall the results obtained from the experiments are in agreement with the limit for splitting tensile strengths of 1.4 to 2 MPa as stipulated in FIP manual (1983) for grade 20 LWAC. FIP manual gives the following equation for calculating flexural tensile strengths for LWAC:

f cmr = c fcu2/3 (2)

Where fcmr and fcu are the flexural tensile strength and cube compressive strengths respectively in MPa. The value of constant c is 0.3 for rounded aggregates.

The flexural strengths summarized in Table 6 are found to be higher than the values calculated using the abovementioned equation. The flexural strength of mixes A1 to A3 was found to be higher by about 14%. As mentioned, the smaller particles with flaky and angular surfaces are well bonded into the concrete and produce higher flexural strengths and the failure is governed by the fracture of PKS. However the mix A5 showed about 3% less value than the value shown calculated by the equation 2. From the examination at the failure surface of flexural specimens, it was evident that the fracture of medium size PKS combined with bond failure of particles larger than 10 mm govern the failure. The bond failure along the convex surfaces of PKS more than 10 mm sizes was visible in specimens of the mix A5 and it produced 28% lower modulus of rupture than mix A1. And hence it can be concluded that exclusion of medium size particles produce lower flexural strength.

Modulus of elasticity

E-values compared to mixes that contain large fraction of smaller and medium size particles.

Conclusions

Based on the experimental results on PKS and PKSC that contained different sizes and proportion of PKS, the following can be concluded:

1. The medium size particles of size ranging from 5 to 10 mm account for about 65 to 70% of the total mass; the small size (S) PKS particles have higher relative density, while the particles of 10 mm and above are tougher and harder as seen from their low abrasion and impact values.

2. The size and proportions of PKS have slight influence on the fresh and hardened densities of PKSC and an increase in density of about 4% was noticed in concrete containing smaller particles owing to higher particle density. The air and oven dry densities were 50 to 100 and 175 to 215 kg/m3 respectively lower than the fresh densities.

3. The mix that contained all particle sizes produced the highest compressive strength. The exclusion of less than 5 mm and more than 10 mm has negative influence on the strength and a strength reduction of about 11% was noticed. Hence it is suggested that the particles of all sizes can be used to produce PKSC.

4. The compression failure of specimens with smaller and medium size PKS was governed by the strength of PKS, while both fracture of PKS and bond failure governed the failure of specimens made with PKS of medium and bigger sizes. The convex smooth surfaces of bigger PKS particles produce weaker bond.

5. The particle size affects the flexural strength as a reduction of about 28% was noticed in specimens that contained 70% of particles of size more than 10 mm. The 28-day splitting tensile and flexural strengths were about 7 and 12 % of their respective compressive strengths. 6. The inclusion of about 70% of PKS of tougher and harder shells of more than 10 mm produced the highest modulus of elasticity of about 11 GPa. However, the use of large size particles in large quantity has negative influence on compressive strength due to bond failure and hence the use of all particles sizes is suggested for the production of PKSC.

ACKNOWLEDGEMENT

This research work is funded by University of Malaya under University of Malaya Research Grant (UMRG) no. RG085/10AET.

REFERENCES

Abdullah AAA (1984). Basic Strength Properties of Lightweight Concrete Using Agricultural Wastes as Aggregates, Proceedings of International Conference on Low-cost Housing for Developing

Countries, Roorkee, India.

Alengaram UJ, Jumaat MZ, Mahmud H (2008). Ductility Behaviour of Reinforced Palm Kernel Shell Concrete Beams. Eur. J. Scientific Res., 23: 406-420.

Alengaram UJ, Jumaat MZ, Mahmud H (2008a). Influence of cementitious materials and aggregate content on compressive strength of palm kernel shell concrete. J. Appl. Sci., 8: 3207-3213. ASTM C 127 (2003). Standard Test Method for Density, Relative

Density and Absorption of Coarse Aggregate. Annual Book of ASTM Standards.

ASTM C 136 (2003). Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. Annual Book of ASTM Standards.

ASTM C 138 (2003). Standard Test Method for Density, Yield and Air Content. Annual Book of ASTM Standards.

ASTM C 29/C29M (2003). Standard Test Method for Bulk Density and Voids in Aggregate. Annual Book of ASTM Standards.

ASTM C 535 (2003). Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. Annual Book of ASTM Standards. BS 812-112:1990 (2000). Testing aggregates. Method for determination

of aggregate impact value (AIV) British Standards Institution. BS EN 12350-2 (2000). Testing fresh concrete-Part-2: Slump test,

British Standards Institution 2000.

BS EN 12350-5 (2000). Testing fresh concrete-Part-5: Flow table test, British Standards Institution 2000.

BS EN 12390-3 (2002). Testing hardened concrete-Part-3: Compressive strength of test specimens, British Standards Institution. BS EN 12390-5 (2000). Testing hardened concrete-Part-5: Flexural

strength of test specimens, British Standards Institution.

BS EN 12390-6 (2000). Testing hardened concrete-Part-6: Tensile Splitting strength of test specimens, British Standards Institution. BS EN 1352 (1997). Determination of static modulus of elasticity under

compression of autoclaved aerated concrete or lightweight aggregate concrete with open structure, British Standards Institution.

FIP Manual of Lightweight Aggregate Concrete (1983). 2nd ed. London: Surrey University Press. Glasgow, London.

Clarke JL (1993). Structural lightweight aggregate concrete, 1st ed., Glasgow: Chapman Hall, London.

Jumaat MZ, Alengaram UJ, Mahmud H (2009). Shear Strength of Oil Palm Shell Foamed Concrete Beams. Mater. Design, 30: 2227-2236. Mahmud H, Jumaat MZ, Alengaram UJ (2009). Influence of

sand/cement ratio on mechanical properties of palm kernel shell concrete. J. Appl. Sci., 9: 1764-1769.

Malhotra VM, Carette CG, Sivasundaram V (1992). Role of silica fume in concrete: A review, Advances in Concrete Technology, CANMET-Energy, Mines and Resources, Ottawa, Canada, pp. 925-991. Mannan MA, Basri HB, Zain MFM, Islam MN (2002). Effect of curing

conditions on the properties of OPS-concrete. Build. Environ., 37: 1167-1171.

Mannan MA, Ganapathy C (2002). Engineering properties of concrete with oil palm shell as coarse aggregate. Cons. Build. Mater., 16: 29-34.

Mannan MA, Ganapathy C (2004). Concrete from an agricultural waste-oil palm shell (OPS). Build. Environ., 39: 441-448.

MS 522: Part (2003). Portland Cement (Ordinary and rapid-hardening): Part 1: Specification, Standards Malaysia. Cyberjaya, Malaysia. Neville AM (1995). Properties of concrete, 4th ed. London, Longman

Group Limited; 1995.

Okafor FO (1988). Palm kernel shell as aggregate for concrete. Cement and Concrete Research, 18: 901-910.

Olanipekun EA, Oluola KO, Ata O (2006). A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ., 41: 297-301.

Robert L, Lindon S, Peter W, Ray R (2003). Cementitious additions. In: John N, Ban SC, editors. Advanced Concrete Technology, Elsevier publications, Amsterdam.

Short A, Kinniburgh W (1978). Lightweight Concrete, third ed., Applied Science Publication, London.