Author for correspondence:

1ME Thermal scholar, Department of Mechanical Engineering, Jayam college of Engineering and Technology,

Dharmapuri, Tamil nadu, India 636 810.

Volume-5 Issue-3

International Journal of Intellectual Advancements

and Research in Engineering Computations

Refrigerators energy conservation

Manojkumar S,

Vetrivel P

ABSTRACT

Investigations are under way to conserve energy in refrigeration and air conditioning system which alone contributes around 15% of total world’s energy consumption. Application of energy efficient compressors, air handling units (AHUs), condensers and evaporators of high effectiveness are the some of the measures towards energy conservation in refrigeration systems. Cooling of compressor shell with the defrost drips is an energy saving measure which is explored in this paper. The quantity of defrost water formation depends upon the types of stuffs preserved, methods of packing and preservation, frequency of door opening, duration of door opening and the relative humidity (RH) and dry bulb temperature (DBT) of ambient. In tropical countries which have 70 to 80% RH year round, the quantity of defrost formation is significant while refrigeration systems are on. This defrost water is dripped on the compressor’s shell, which in turn cools the compressor oil and hence reduces the friction losses and winding temperature of the motor. Once winding temperature is reduced the compressor’s ampere rating is reduced which ultimately reduces the energy consumption of the compressor. For given conditions of refrigerator function, the compressor shell temperature and ampere rating of compressor are tabulated and investigated before and after compressor shell cooling. The investigation reveals that around 8-10% energy savings are achieved for the given conditions.

Keywords:

Defrost drip, Shell cooling, Indirect Cool Refrigerator, Direct cool refrigerator.INTRODUCTION

This paper aims to improve the energy efficiency of refrigerator by using the defrost drips for shell cooling to reduce ampere rate. Therefore, any reduction in energy consumption will result in reduced CO2 emissions as well as reduced power bills for the end user of the refrigerator.

In order to justify the decision to focus on reducing the energy usage of the refrigerator this paper needs to consider the whole life cycle of a refrigerator, including resources, raw materials, manufacturing, use and end-of life. A comprehensive LCA (Life Cycle Analysis) will take a considerable amount of time and resources which is beyond the scope of this paper. Yuhta Alan Horie [1], from Centre of Sustainable Systems at University of Michigan report states that

according LCA studies conducted in Europe, Japan and the U.S; 88% to 97% of total refrigerator life cycle energy is consumed in the use phase regardless of the product size or lifetime (Foley; JEMAI 1995).Hence, this study is restricted only on use phase and tries to enhance its useful life with optimal energy consumption. Arroyo-Cabanas et al. [2] carried out an investigation to save electrical energy by replacing the aged and inefficient refrigerators in Canada in a phased manner over five years. They have reported energy savings of 4.7 TWh/year, 33% of total energy consumption upon substituting the low efficient machines.

Implementation of energy efficiency standard GBI 2021.2-2003, for refrigerators were explored by Wei Lu [3] to save large amount of energy in China annually. With a mathematical modeling, he

estimated the quantum of energy savings and environmental benefits. A steady state simulation was carried out by Christian J.H. Hermes et al. [4] for the purpose of prediction of energy consumption of household refrigerators and freezers. Employing sophisticated dynamic simulation codes, they simulated thermal performance results of a test refrigerator and compared the results with the experimental data and reported 5% deviation band. They also studied about the sensitivity analysis on the test refrigerator’s components viz. the number of coils in the condenser, the number of fins in the evaporator and stroke length of compressor. A dynamic simulation on energy performance assessment was also carried out by Christian J.H. Hermes et al.[5] to assess the influence of refrigerator components such as capillary tube-suction line heat exchanger geometry, compressor capacity , internal air flow rate and thermostat settings. It was found that the system’s simulated energy consumption results were within 10% deviation from the experimental data..

Standards and labeling programme for refrigerators of India was compared with other countries like China, European Union and USA by Aditya Chunekar [6]. He reports that refrigerators alone consume about 14% of total residential

energy consumption in India. A normalization method proposed by International Energy Agency was used as bench mark to compare India’s programmes with other countries in this connection. Performance enhancement of domestic refrigerators with thermal storage was proposed by A.C.Marques et al. [7]. He proposes a method to store the excess cooling capacity in a Phase Change Material and reducing the number of on-off cycles of compressors. Depending upon the ambient conditions and the PCM material volume the refrigerator could go without power supply for 3-5 hours. He reports 5% deviation between simulated and experimental data

All the above papers explore the options of energy efficiency in refrigerator in one way or other. As about 15% of the world’s electricity is used to drive refrigerating and air conditioning systems, inefficient use of energy is a waste of valuable resource and contributes to global warming. Most of the Global warming effect of refrigerating systems comes from generating energy to drive them. In our experimental study, defrost drips from the refrigerator are allowed to flow over the shell of the compressor and the compressor shell temperature is reduced to enhance the energy efficiency. Table.1 gives the COP of different refrigerating systems.

COP of different refrigerating systems

Table1. COP of different refrigerating systems System COP

Vapour compression 1.3

Absorption system 0.2‐0.3 Thermoelectric system 0.1‐0.2

The high-pressure refrigerant liquid is reduced to a low pressure at the expansion valve. At low pressure, the refrigerant will evaporate at a low temperature enabling it to extract heat from the substance to be cooled. To complete the cycle, the low pressure refrigerant vapor exiting the evaporator is compressed to high pressure by the compressor. The total heat rejected in the condenser is the sum of the heat extracted plus the compressor energy use.

EXPERIMENTAL DESCRIPTION

Figure.1.Schematic diagram of the experimental apparatus.

1: Air circulating fan,2: Fin and tube evaporator cooling coil, 3: Defrost heater (Nikrome filament-80 W), 4: Drain channel,5: Drain pipe, 6: Defrost timer (Electro mechanical 6 Hrs), 7: Drain cup, 8: Compressor shell, 9: Drain tray ,10: Water proof motor terminals, 11: Ammeter (0-10 A), 12: Watt meter (0-500w), 13: Energy meter (5-20A), 14: AC supply mains, 15: Voltmeter (0-240V),T1: Thermometer at point 1,T2: Thermometer at point 2,T3:Thermometer at point 3,T4 Thermometer at point 4.

Data on energy consumption (E), ampere rating (i) and compressor shell temp Tavg of the test

refrigerator are obtained before and after shell cooling for different dates, keeping the refrigerator load at 50%, 75% and 100%. The graphs are plotted based on data collected and the conclusions drawn based on results.

RESULTS AND DISCUSSIONS

The test refrigerator is loaded 50% of its capacity and readings are taken before and after activating the drip cooling system. The variables (Tb), (Ta), (ib), (ia), (Eb), (Ea),(Pb) and (Pa) are recorded and tabulated for 30 days trial.

Effects of defrost cooling on compressor energy consumption 50% loading

Figure 3.1 Effects of defrost cooling on compressor energy consumption 50% loading

1

2 3

4

5

6 7

8

9

10

A V

14 13 15 12 11

W

E

T1

T2

T3 T4

Effects of defrost cooling on compressor energy consumption 75% loading

Figure 3.2 Effects of defrost cooling on compressor energy consumption 75% loading

Effects of defrost cooling on compressor energy consumption 100% loading

Figure 3.3 Effects of defrost cooling on compressor energy consumption 100% loading

Effects of defrost current on compressor energy consumption 50% loading

Figure 3.4 Effects of defrost current on compressor energy consumption 50% loading

Effects of defrost current on compressor energy consumption 75% loading

Figure 3.5 Effects of defrost current on compressor energy consumption 75% loading

Effects of defrost current on compressor energy consumption 100% loading

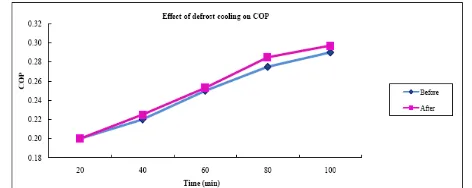

Effects of defrost COP consumption 50% loading

Figure 3.7 Effects of defrost COP consumption 50% loading

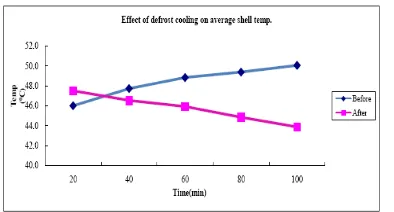

Effects of defrost COP consumption 75% loading

Figure 3.8 Effects of defrost COP consumption 75% loading

Effects of defrost COP consumption 100% loading

Figure 3.9 Effects of defrost COP consumption 100% loading

CONCLUSIONS

In this research, an experimental case study was carried out to explore the effects of drip cooling on energy consumption in a indirect cool refrigerator. Upon employing drip cooling system for the given conditions the heat removal rate from the compressor shell is increased and due to which the average shell temperature of the compressor falls by 4.2°C, a 6.5% reduction in shell temperature.

1. The reduced shell temperature results in enhanced heat transfer from the lubricating oil

and hence the reduced winding temperature which results in reduction of current consumption from 1.075A to 0.85A, reduction of 21%.

2. Reduced power consumption results in improvement of COP by 10.3% for the given operating conditions.

REFERENCES

[1]. Yuhta Alan Horie. Life Cycle Optimization of Household Refrigerator-Freezer Replacement, A thesis Submitted in partial fulfillment of the requirements for the degree of Master of Science in the University of Michigan, 2004 [2]. F.G. Arryo-Cabanas, J.E. Aguillon- Martinez,J.J.Ambriz-Garcia,G.Canizal. Electri energy saving potential by

substitution of domestic refrigerators in Maxico, Energy Policy 37, 2009, 4737-4742.

[3]. Wei Lu. Potential energy savings and environmental impact by implementing energy efficiency standard for household refrigerators in China, Energy Policy 34, 2006, 1583-1589

[4]. Chrisitian J.L.Herms, Claudio Melo, Fernando T.Knabben, Joaquim M. Goncalves. Prediction of the energy consumption of household refrigerators and freezers via steady- state simulation, Applied Energy 86, 2009, 1311-1319

[5]. Chrisitian J.L.Herms, Claudio Melo. Assessment of the energy performance of household refrigerators Via dynamic simulation, Applied Thermal Engineering 29, 2009, 1153-1165

[6]. Aditya Chunekar, Standards and Labeling for refrigerators: Comparing India with others, Energy Policy 65(2014) 626-630