Rochester Institute of Technology

RIT Scholar Works

Theses

Thesis/Dissertation Collections

4-1-1992

A Procedure to characterize electron-beam resist

using a scanning electron microscope and study of

process optimization of an electron beam imaging

system using experimental design methods

Randall C. Pyles

Follow this and additional works at:

http://scholarworks.rit.edu/theses

This Thesis is brought to you for free and open access by the Thesis/Dissertation Collections at RIT Scholar Works. It has been accepted for inclusion

in Theses by an authorized administrator of RIT Scholar Works. For more information, please contact

ritscholarworks@rit.edu

.

Recommended Citation

A PROCBDURE TO

CHARACTBRIZB BLECTRON-BEAK RESIST

USING A SCANNING BLECTRON MICROSCOPB

STUDY OF PROCBSS OPTIKIZATION

OF AN BLBCTRON BEAK IMAGING SYSTBM

USING BXPBRIMENTAL DBSIGN METHODS

by

Randall C. Pyles

B.S. Temple University

(1983)

A thesis submitted in partial fulfillment

of the requirements for the degree of

Master of Science in the Center for

Imaging Science in the College of

Graphic Arts and Photography of the

Rochester Institute of Technology

April 1992

Signature of the Author

R_a_n_d_a__

l_l__

C_.__

Py~l_e_s

___

COLLEGE OF GRAPHIC ARTS AND PHOTOGRAPHY

ROCHESTER INSTITUTE OF TECHNOLOGY

ROCHESTER, NEW YORK

CERTIFICATE OF APPROVAL

M.S. DEGREE THESIS

The M.S. Degree Thesis of Randall C. Pyles

has been examined and approved

by the thesis committee as satisfactory

for the thesis requirement for the

Master of Science Degree

Dr. Lynn Fuller, Thesis Advisor

Dr. Robert Daly

Dr. Dana Marsh

Date

THESIS RELEASE PERMISSION FORM

ROCHESTER INSTITUTE OF TECHNOLOGY

COLLEGE OF GRAPHIC ARTS AND PHOTOGRAPHY

Title of Thesis

A PROCEDURE TO CHARACTERIZE

ELECTRON-BEAM RESIST USING A SCANNING ELECTRON MICROSCOPE AND STUDY OF

PROCESS OPTIMIZATION OF AN ELECTRON BEAM IMAGING SYSTEM USING

EXPERIMENTAL DESIGN METHODS

I,

Randall

C.

Pvles

,

hereby grant permission to the

Wallace Memorial

Library of RIT to reproduce my thesis

in

whole or in part.

Any reproduction will not be for commercial

use or profit.

:--74~,--...:-'?o~?L-~.L...·'='£~----A

PROCEDURE

TO

CHARACTERIZE

ELECTRON-BEAM RESIST

USING A

SCANNING

ELECTRON

MICROSCOPE

AND

STUDY

OF

PROCESS

OPTIMIZATION

OF

AN

ELECTRON BEAM

IMAGING

SYSTEM

USING

EXPERIMENTAL

DESIGN METHODS

by

Randall

C.

Pyles

Submitted

to

the

Center

for

Imaging

Science

in

partialfulfillment

ofthe

requirements

for

the

Master

ofScience

Degree

at

the

Rochester

Institute

ofTechnology

ABSTRACT

A

procedureis

established whichwill

enable

the study

of

contrast and

sensitivity

characteristicsof

electron-beam

resist materials.

The

imaging

system

includes

an

electron

beam-sensitive

resistcoating

onan

oxidizedsilicon substrate

exposed with a

scanning

electronmicroscope

(SEM)

and

developed

in

a

suitable solvent.The

results

correlate

with

published

data.

A

chemically

amplified

electron-beam

resist

imaging

systemis

studiedusing

a

three

level,

three

factor

Box-Behnken

design.

The

effectsof

postbaketemperature,

postbake

time,

anddevelopment

time

on

contrast

and

ACKNOWLEDGEMENTS

Successful

completion

ofthis thesis

owes recognitionto

support

from

several

sources.Supplies

of electron-beamresist

material

areparticularly

appreciatedfrom

Eastman

Kodak

Research

Laboratories,

Mead

Imaging Technologies,

and

the

Shipley

Company.

Graciously

acknowledgedis

the

use,

during

a portion ofthis project,

of

aNanospec

film thickness

measurementinstrument

in

care ofMr.

John

Guild

ofthe

Eastman Kodak Research Laboratories.

Special thanks

are givento Mr.

Bruce Smith

for

continued supportthroughout the

second

phase

ofthis

project andto

Mr.

Richard

Holscher

for

his

TABLE

OF

CONTENTS

ABSTRACT

i

ACKNOWLEDGMENTS

ii

INTRODUCTION

1

METHODS

34

RESULTS

63

DISCUSSION

81

CONCLUSION

91

APPENDIX A

-Resist Data Sheets

92

APPENDIX B

-SAL-601 Characteristic Curves

100

LIST

OF

FIGURES

Figure

Title

Page

1

Schematic

ofLithography

using

Negative

2

and

Positive

Resists

2

Diazonaphthoquinone-novolac

Exposure

7

Reaction

3

Electron-Beam

Exposure

System

18

4

Scanning

Electron

Microscope

Cross

Section.

.. .275

MEBES

Electron

Optical

Column

30

6

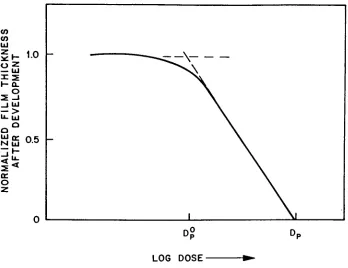

Characteristic

Curve

Example

for

39

Negative

Resist

7

Characteristic

Curve

Example

for

40

Positive

Resist

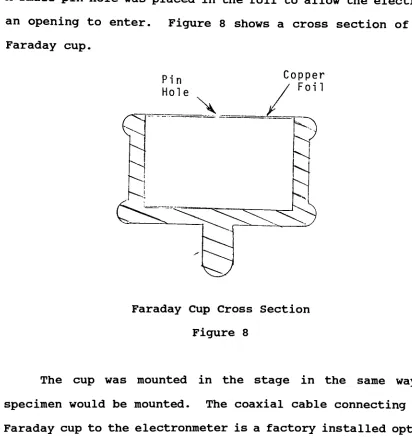

8

Faraday Cup

Cross

Section

41

9

Electronmeter

-Current

to

Voltage

Schematic.

.4210

Three

Factor

Box-Behnken

Design

Geometry

54

11

MEBES

Individual

Exposure

Pattern

60

12

MEBES

Repeat

Exposure

Pattern

61

13

ZX-784

Spin

Curve

65

14

PMMA

Spin

Curve

65

15

COP

Spin

Curve

66

16

ZX-784

Characteristic

Curve

70

17

PMMA

Characteristic

Curve

70

LIST

OF

TABLES

Table

Title

Page

1

Unrandomized

Experimental

Schedule

56

2

ZX-784

Spin

Speed

Data

63

3

PMMA

Spin

Speed

Data

64

4

COP

Spin

Speed

Data

64

5

ZX-784

Exposure

Data

67

6

PMMA

Exposure

Data

68

7

COP

Exposure

Data

69

8

Contrast

andSensitivity Summary

71

9

SAL-601

Data

Summary

75

10

Average

Sensitivity

as aFunction

of74

Factor

Level

11

Average

Contrast

asa

Function

of

76

Factor

Level

12

ANOVA

for

Sensitivity

77

13

Analysis

of

Regression

Variance

for

78

Sensitivity

14

Detailed

Analysis

ofRegression

79

Variance

for

Sensitivity

15

ANOVA

for

Contrast

80

16

Comparison

ofCharacteristic

Data

83

for

ZX-784

17

Comparison

ofCharacteristic

Data

83

for

PMMA

INTRODUCTION

Resist

History

There

has been

exponential

growth

in

the

applications

of

high

technology during

the

pasttwo to three

decades.

Solid-state

devices

andmicroelectronics

have

become

an

integral

part

of

daily

life.

Microelectronic

applications

have

dictated

that

devices

become

faster,

reach

higher

levels

ofperformance,

andincrease

packaging

density

without

raising

costs and

decreasing

reliability.The

accomplishment

of

these

goals requires ever more complex

designs.

These

designs have

evolved

into very

large-scale

integration

(VLSI)

ofelectronic

devices

[Lai,

1985].

The

trend

ofincreased

design

complexity

has

put

severedemands

onthe

fabrication

industry

to

manufactureintegrated

circuit

devices

with submicrondimensions.

"Lithography

is

a

key

technology

for

producing

LSIs

with

increased

speed

and

packing

density"[Sakakibara,

et

al.,

1981,

p.

1279].

The

fabrication

process can nottotally

overcomethe

limitations

of

the

transfer

of patterndefinition

onto

the

semiconductor

material.

The

cornerstone ofthe

lithography

process

is the

resist

material.

The

resist"serves

to

protectportions

of

surfaces

of

the

substrate wafersduring

certainsteps

of

processing.

.image-wise

layer

formed

from

alight-sensitive

material

by

exposure

to

a

master

pattern,

soas

to

produce

aprotective

stencil on a surface

and

allow modification ofthe

surfacein

such

a

way

as

to

givea

complementary

orcorresponding

image"[Hepher,

1964,

p.181].

Generally,

photoresists are polymerswhich

are

sensitivein

the

deep

blue

andultraviolet

regionsof

the

electromagnetic

spectrum.Patterned

areas

ofthe

photoresist

will

change

in

solubility

when

exposed.Insolubility

ofthe

resist materialin

the

exposed areasdescribes

anegative-acting

resist.The

opposite actionis

also possible.

In

apositive-acting resist,

the

exposed areasbecome

soluble anddevelop

away.A

schematicrepresentation

of

patterning

negative and positive resistsis

illustrated in

Figure

1

. EXPOSINGRADIATION

IRRADIATED REGION

\\

\)

THIN FILM SUBSTRATESchematic

of

Lithography

Using

Negative

andPositive

Resists

[image:11.546.174.382.401.620.2]Present-day

lithography

techniques

evolvedfrom

early

photo-etching

processes,

which

were appliedto

the

printing

industry.

This

evolution

was made possibleby

continued

success

in

development

of

resist

chemistry.The

characteristics

of

the

resist

have been

found to be the

most

important

elements

in

alithographic

system."Historically

the

photo-resistis

of

considerablesignificance and

it

is

generally

acceptedthat

the

first

camera picture ever

to

have

been

recorded wasmade

by

Niepce

with

a photo-resist method"[Hepher,

1964,

p.

181].

In

1826

J.N.

Niepce

discovered

that

alayer

ofbitumen,

acomplex

hydro-carbon

preparedfrom asphalt,

coatedon

asilvered

glasssubstrate was photosensitive and capable of

producing

animage

when exposed

to

light

for

severalhours

[Hepher,

1964].

The

bitumen

wasinherently

photosensitivebecause

of acertain

degree

of

unsaturationin

the

molecularbonding.

The

long

exposure

to

short wavelengths oflight

removed

the

saturation

due

to

molecular crosslinking.

The

exposedregions

became

insoluble in

a mixture of oil oflavender

andmineral

spirits.

With

this

technique

he

was ableto

create

the

world's

first

permanent

images

andto

usethese

images

to

etchdesigns

on

several mediums.

In

practice,

he

had

used

to

his

advantage

the

changein

solubility

of

a

materialupon

exposure

to light.

This

is

the

fundamental

characteristicassumed

in

resist

found

wide-spread

acceptance;

however,

the

length

ofthe

exposure

was

unreasonable.

Niepce

sdiscovery

neverreached

the

importance

of

the

development

of aphotoetching

processwhich

used

gelatinsensitized

with

chromium

salts

asthe

resist.

In

1852,

W.H.F.

Talbot

received

aBritish

patent

for

this

process,

which

he

applied

to

etching

copper

[DeForest,

1975].

It

was

found that

many

naturalcolloids

and

resins

could

be

photo-crossl

inked

when

sensitized

with

dichromate

salt.The

availability

ofthe

materials used and

the

decreased

exposure

times

madethis

system much more

practical

than

Niepce's method.

Hence,

it

has

continuedto

receive attention as a useful resistsystem.

It

wasfound,

however,

that

the

coatedlayer

wasunstable

andhad

a

tendency

to become

insoluble in

the

dark,

and

that

only

water-soluble colloids responded

well

to

dichromate

sensitization.

Also,

the

developed

image

wasfound

to

be

poorly

resistantto

etching

chemistry

and notimpermeable

to

water

[Hepher,

1964;

DeForest,

1975;

Pyles,

1985].

Efforts to

overcome

these

drawbacks

continued.Extended

researchspawned an

array

of

alternate

configur

ations.

These

include

resistswith

water-insoluble

resins

to

provide etch-resistant

images

and spectralsensitization with

dyes

to

increase

the

light

sensitivity

ofthe

system

to

include

longer

wavelengths[DeForest,

1975].

Alternate

The

first

"modern"photo-resist

systems werebased

on

cinnamic

acid

derivatives,

which

are

inherently

photosensi

tive.

Cinnamic

acid

derivatives

are

not

ableto

form

uniform

coatings

themselves,

but

areappended

asside

groups onpolymers

to

increase

their

film-forming

capability

[DeForest,

1975].

These

resins act ascarrying

agents anddo

not addmuch

to the

solubility

changes.

However,

very

stable

coatingscan

be

formed.

These

systemswere

found

to

be

several

times

faster

than

the

dichromated

colloids.They

alsohave

a widedevelopment

latitude

and show excellentresistance

to

water-based

etchants[Pyles,

1985].

The

initial

discovery

ofthe

sensitivity

of cinnamicacid

was made at

the

turn

ofthe

century.Research

in

these

systems

increased

in

the

1930s

and1940s

andled

to

the

synthesis of cinnamic acid esters of polyvinyl alcohol.

This

system provides a polymer with photosensitive side groups.

In

the

early

1950s

Kodak

marketedKPR

(Kodak

photoresist)

, apoly-vinyl cinnamate material

based

onthis

system

[Pyles,

1985].

KPR

is

typical

of cinnamate systems withoutstanding

dark

reaction stability.The

release ofthis

system

dramatically

influenced

the

expansion ofmodern

photo-resists.

This

began

an age oflarge

expansionin

the

electronics

industry

witha

corresponding

evolutionof

resist

systems

designed

to

meetit.

resist

systems.

The

most

notable are compoundsbased

onnovolac or

m-cresol

novolac

resins anddiazonaphthoquinone

sensitizer.

"Such

materials

are coatedfrom

an organicsolvent

and,

afterexposure

to

light,

are

treated

in

aqueousalkali which

removes

the

light

struck areasleaving

the

remaining

parts

to

form

apositive

image

with

good resistanceto

acidetching

solutions"[M.

Hepher,

1964,

p.

189].

These

compounds

have

formed the

basis

for the

mostpopular

positiveresist systems.

The

imaging

reaction mechanismis

suchthat

upon exposureto

light

nitrogenis

released and anintermediate

ketene

is

formed.

In

the

presence ofwater,

anindene

carboxylic acidresults

following

a molecular rearrangementby

the

Wolff

mechanism.

The

carboxylic acid exhibitssolubility in

aqueous

base

developers

[Blevins,

etal.,

1987;

Goncher,

etal.,

1988].

These

systems comprisethe

backbone

for

the

microelectronics

industry

in

terms

of

positiveoptical

resist

chemistry.

The

exposure reaction ofthis

nature

is indicated

in

Figure

2

.Electron-Beam

Resists

To

meetthe

demand

for

continuing

miniaturization

of

integrated

circuitry,

resist materialshave

been

designed

to

be

used with non-optical exposuretechnologies.

+

HoC

=O

H+

Base

Insoluble

Sensitizer

OH

OH

>"'ft

NovolakResin

H,0

+

N2

Base

Soluble

Photoproduct

Diazonaphthoquinone-novolac

Exposure

Reaction

Figure

2

polymers of

high

molecular weight.In

general,

both

crosslinking

and chain scission eventsoccur

to

different

degrees

in

the

same polymer.When

both

occurin

relatively

equal

amounts,

the

resisthas

very

poorcharacteristics.

The

early

workin

electron-beamlithography

usedoptical

resist,

but

it

was soondiscovered

that

simplenon-light-sensitive

polymer

and copolymer materials were electron

beam sensitive,

and

the

present electron resists

have

evolvedfrom this

discovery.

Positive

Resists

Electron

beam

exposurethat

causespredominantly

chain

scission

to

occurin

polymer molecules resultsin

apositive

[image:16.546.160.387.14.286.2]to

decrease

andallows

removal

by

a solvent.A

notable

group

ofpositive

resist

materialsis

the

methyl-acrylate

family.

Perhaps

the

best

known

exampleis

poly

(methylmeth-acrylate)

,PMMA,

which

is

a

common

material

known

under

the

trade

namesof

Lucite

and

Plexiglass

[Brewer,

1980]].

PMMA

is

apositive

resist

which

has

received

considerable

attention

in

electron-beamapplications.

It

is

a

singlehomogeneous

material

that

has

excellent

characteristics,

including

resistanceto

wetchemical

etchantsand

excellentfilm

forming

properties.PMMA

has been

studied

by

a number of workers whofound

it

to

be

capable of excellent(ljim)

resolution upon electron-beam exposure[Chandross,

et

al.,

1981].

However,

it

wasfound

that

the

sensitivity

ofPMMA

is

too

low

to

be

used as a productionresist,

andPMMA

has

poordry

etchdurability.

The

other

family

members

ofthis group

are madeby

replacing the

side

radical

or

by

making

a copolymer.

This

has

been

done

to

try

to

increase

sensitivity

while

retaining

the

otherexcellent

properties.

The

search continuedfor

a

more

sensitive

positive

resist.

The

polyolefin sulfonefamily

has

been

found

to

be

highly

sensitiveto

electronbeam

exposure.

Poly

(

1-butene

sulfone)

,PBS,

has

the

best

resist

properties

ofthe

group.

PBS

is

muchfaster

than

PMMA

and

sensitive

enough

to

be

commercialized as an electron-beam

mask-making

resist.

As

a

on

the

market

today

[Gozdz,

1987].

The

biggest

disadvantage

of

PBS

is

that

the

resolution

and

dry

etch

resistance

is

poorer

than

PMMA.

Negative

Resists

Until

1981

there

wasgreat

emphasis

on

the

searchfor

and

study

of positiveworking

electron

resists,

but

in

1982

this

changed,

and

moreattention

wasdirected to

negative

working

resists

[Roberts,

1984].

Crosslinking

occursin

the

exposed

areas of a negative

resist

material.

This

resultsin

anincrease

in

molecular weight and acorresponding

decrease

in

solubility.

"Intense

investigation

in

this

field

led

to

the

conclusion

that

polystyrenehas

outstanding

characteristics

when compared

to

otherpolymers;

and sothis

polymer

gainedprominence and

took

a position similarto

that

taken

by

PMMA

among

positive resists.A

seriousdisadvantage

affixed

to

polystyrene refers

to

its

ratherlow

radiationsensitivity

andmany

attempts weretaken

to

improve

radiation susceptibility"[Schnabel

&

Sotobayashi,

1983,

p.331].

Several

derivatives

of polystyrenehave

been

investigated

in

the

searchfor

increased

sensitivity.Poly

(chlorme

thy

1-styrene)

has

emerged as ahighly

sensitiveresist

with

excellent etch resistance and resolution

compared

to

PMMA.

This

has

led

to

its

increased

usethroughout

the

industry.

and

related

copolymershave

also

been

found

to

have

superiornegative resist

characteristicsand

therefore have

gained wide

acceptance

[Blevins,

etal.,

1987],

Monomers

with

other

desirable

resist

properties,

particularly adhesion,

have

been

joined

with

the

high

sensitivity

of

the

glycidyl

monomer

to

form

goodresists.

The

copolymer

of

glycidyl

methacrylate

and

ethyl acrylate

(COP)

has

been

found to be

highly

sensitiveto

electron

exposure

and

have

good

film

forming

properties.

The

problem with

these

systemshas

been

the

need

for

postcuring

and poor

resistance

to

dry

etching.Other

polymers wereformed

with

glycidyl methacrylate andallyl

methacrylate,

another monomerthat

is

sensitiveto

electron

beam

exposure.This

polymer was studied atthe

Eastman

Kodak

Research Laboratories

andis

one resist materialthat

was also studiedin

this

research

project[Tan,

etal.,

1984].

This

copolymer showshigh

sensitivity

andresolution,

good resist

properties,

and gooddry

andchemical

etchresistance.

In

general,

the

negativeresist

systemsdo

not

exhibit

the

resolution ofPBS

orthe

numerousacrylate

based

positive resists.

Chemically

Amplified

Resists

The

resist materialspreviously discussed

each

have their

advantages,

but there

is

not one whichhas

properties

of

high

etching.

Researchers

at

the Rohm

andHaas

Company

stated

that

it

was

their

intent

to

develop

a

resist material

that had

good

performance

characteristics

in

all

of

these

areas.

[Liu,

et

al,

1988]

The

result was

the development

of

a

three-component

negative

resist

with

chemical

amplification.

The

chemical

amplification

of

this

material

results

from

aformation

of anacid

upon

electron-beam

exposure.

During

the

postexposure

baking

the

acid

catalyzes

the

bonding

between

the

resin

base

and

the

crosslinking

material.

Each

catalyst

molecule canreact more

than

once

and

contributeto

many

crosslinking

reactions,

hence

amplification occurs.[deGrandpre,

etal,

1988;

Lamola,

et

al,

1991]

The Rohm

and

Haas

and

Shipley

Companies

have

succeeded

in

marketing

aversion

ofthis

resist underthe

trade

nameMicroposit SAL

601-ER7.

The

chemistry

of

this

resist

includes

a novolac

based

polymerresin,

an

aminoplast

acid

activated

crosslinking component,

and a

photoacid generator.

They

claim

that

this

material providesthe

high

performance

they

sought

in

contrast,

sensitivity,

and

dry

etch

resistance properties.

The

Shipley

has

alsodeveloped

andmarkets

the

SAL

605

electron

beam

resist material.This

is

an

improved

version

of

SAL

601-ER7,

whichis

formulated

for

increased sensitivity

and

Negative

vs.

Positive

Resist

The

decision

to

use

negative

or

positive

resist

will

depend

on

the

application

and

an

analysis

of

the

advantages

and

disadvantages

of

both.

In

general,

the

advantages

of

negative

resists

are

higher

sensitivity,

spectral

sensi

tization,

good

adherence

and

coating,

andlower

cost.However,

negative

resists

aresensitive

to

oxidation,

they

require

organic

developers

which

cause

pollution,

and

their

resolution

is

limited

because

they

tend

to

swell

during

development.

Positive

resists providebetter resolution,

less

pollution

and

better

step

coverageof

wafer

topology.

The

disadvantages

ofusing

apositive

resist

arepoor

adhesion

andslower

speed.Exposure

Technology

Originally

it

wasthought

that

performance

levels

and

density

requirementsof

the

new

generation

of

devices

could

not

be

achievedby

using photolithography for

pattern

defini

tion.

Therefore,

investigation

of alternatepatterning

tech-niques

began

to

take

place.Alternate

techniques

include

short wavelength

lithography,

X-ray

lithography,

ion-beam

lithography,

and

electron-beamlithography.

Recently

it

has

been

shownthat

certain opticaltechniques

surpass

the

resolution

that

wasoriginally

thought

possible

[Fuller,

1987;

resist

technology,

higher

numerical

aperturelenses,

excimerlaser

sources,

and

advances

in

process

techniques.

Although

optical

lithography

continues

to

advance

beyond

original

expectations,

it

is

important

to

continueresearch

into

alternate

techniques.

These

alternatetechniques

arealso

advancing

and

finding

roles

in

integrated

circuit

manufacturing

.Through

extended research

andadvancements,

electron-beamlithography

has

found

a nichein

the

production ofintegrated

circuits.

During

its

infancy,

the

process waslooked

upon

asa

potential

replacementfor

opticallithography

techniques.

Since

then,

its

limitations have been

recognizedand

electron-beam

techniques

emergedto

fill

specificroles.

"The

basis

of

this

technology

is

a

finely

focused

electron

beam

that

is

both

deflected

over a surface andblanked

on

andoff

under computer control.The

electron

beam

exposes

the

resist whereit

strikes..."[Brewer,

1980,

p.

13].

The

resist willthen

be

developed

asin

photolithography

to

leave

a

patternedimage.

Both

positiveand

negative

resist

materials

have been developed

with electronbeam

sensitivity.

The

applicationof

electron-beamtechnology

to

lithog

raphy

techniques

stemmedfrom

the

apparentlimitations

of

photolithography.

One

ofthese

limitations

is

the

minimum

resolution obtainable

through

exposure.Typically,

resolution

R

=NA

where:

k

=0.8for

production

resolution

limits

X

=wavelength

oflight

used

for

exposure

NA

=numerical

aperture

of

the

lens

system

"...When

higher

resolution

is

demanded

andthe

linewidth

is

reduced

to

the

point

that

it

is

comparableto

the

wavelengthof

the

light

used

for

exposure,

diffraction

effects

from

the

mask openings and

reflection

effectswithin

the

resist

degrade

the

quality

ofthe

replicatedimage

ofthe

mask"[Brewer,

1980,

p.7].

"Electrons,

like

photons,

possessparticle

and

wavelength

properties;

however,

their

wavelength

is

onthe

order of a

few

tenths

of anangstrom,

andtherefore

the

resolution

is

notlimited

by

diffraction

considerations.

Therefore,

minimumlinewidths

with electron-beam areless than

photolithography"

[Thompson,

etal.,

1983].

This

theory

is

logical,

but

it is

moredifficult to

apply

in

practical situations."Due

to

the

serial

nature

of

writing,

reductionsin image

size andincreases

in

wafer

size

have

tended

to decrease the throughput

in

terms

ofwafers

per

hour.

. . .Not

-withstanding

the

limited

throughput,

electron-beam

technology

has

been

the

critical

technology

in

mask

writing,

early development

devices,

and now morethan

ever

in

application-specific

integrated

circuits (ASIC)"[A.S.

Oberai,

photolithography,

the

technique

is

too

slowfor

most

production

applications.

Electron-beam

techniques

have

been

given

anactive

role

in

making

masksused

in

optical

lithography,

direct

-writespecialty

applications,

device

prototype

development,

and

proximity

flood

exposure

techniques.

Electron-Beam

Exposure

Systems

True

electron-beam exposure systems aredescendants

ofscanning

electron microscopes(SEM)

, which wereintroduced in

the

1960s.

Along

with

the

developing

acceptance ofelectron-beam

lithography

camethe

needfor

exposure systemsspecifically designed for this

application.Since

the

1960s,

the

SEM

technology

has

been

expandedand

refined

to

permit

high

precision electron-beamimage

"writing" ratherthan

specimen

"reading".

However,

the basic

building

blocks

ofthe

system

have

remainedthe

same.There

aretwo

main exposure philosophieswhich

have been

investigated

during

the

development

ofelectron-beam

imaging

systems as

lithography

tools.

These

categoriescould

be

used

to describe the

mainbranches

of

a

"family

tree"of

electron-beam

exposure systems[Thompson,

etal.,

1983].

These

categories can

be

separatedinto

those

systemswhich

rely

on

a

"projection" of electrons ora

direct

"scanning"

of

the

Exposure

Strategies

Projection

The

development

of projection systems

wasexplored

mainly

to

solve

the low

throughput

problem

that

plagueselectron-beam

systems.

In

this

approach,

the

whole

wafer

is

exposed

at onetime,

rather

than

drawing

anindividual

feature

with

a scannedelectron

beam.

One

type

ofprojection

system employsultra

violet

irradiation

of a masked photocathodeto

create

the

electrons

which exposethe

substrate.

Another

reported

projection system

is

designed

to

reducethe

image

oflarge

metal masks

by

demagnification

ofthe

electronbeam

with electromagneticlenses

[Elliott,

1982].

There

areinherent

problems withthese

systems whichlimits

their

practical

applications,

but

these

continueto

be

addressed.Scanning

The

most mature electronbeam

exposuretechnologies

involve

the

scanning

of an electronbeam

over asensitized

substrate.

The

design

ofthese

unitsmost

closely

resembles

a

SEM.

There

aretwo

primary writing

strategieswhich

are

in

use withscanning

imaging

systems.These

strategiesdiffer

in

the

way

the

substrateis

addressedby

the beam.

The

electron

beam

canbe

controlledby

rasteror

vectormethods.

In

the

raster

method,

the

electronbeam

scansthe

entire

substrate.

The

beam

is

then

turned

on or off atdifferent

positions

in

less

complex

addressing

control

than

the

vectoring

systems.However,

the

exposuretimes

are

limited

by

the

fact

that

the

entire

substrate

needs

to

be

scanned.

In

the

vectoring

method,

the

beam

is

directed

only

atthe

particular areaswhich

needto be

exposed andis blanked

asit

travels

from

onearea

to

another.This

requires more complexbeam

controlsystems,

but

the

exposuretimes

can

be

reducedbecause

little

time

is

lost

asthe beam travels

over areas whichdo

notneed

to

be

addressed.In

additionto

the

scanning

method,

there

is

also anoption

to

adjustthe

shape ofthe

electronbeam.

This

is

particularly

usefulin

the

vectorscanning

systems.This

allows

for

several optionsto

be

usedto

expose orfill

in

agiven area.

The

beam

canbe

programmedto

outline a givenfeature.

Then

the

shape canbe

optimizedin

orderto

expediteexposing

the

entire structure.This

increases

the

speed ofthe

system sincefewer

addresses are neededto

completethe

image

.Equipment

An

electron-beamimaging

system canbe

described

as

acombination

of

four

main subsystems:1)

a

computer

that

provides a means

for

data

input

and patterncontrol,

2)

the

electron-optical column

including

the

electronsource,

3)

the

elements

that

providethe beam

controland

patternexecution,

and power

supplies

for

the

system[Brewer,

1980;

Thompson,

etal.,

1983],

Figure

3

shows

a

simplediagram

of

an

electron-beam

exposure

system

based

on

the

main

subsystems.

X-Y MASK

DATA

COMPUTER

CONTROL

TABLE

POSITION

MONITOR

ELECTRON

GUNBEAM

BLANKING

.

DEFLECTION COILS

VACUUM CHAMBER

ELECTRON

RESIST

METAL FILM

SUBSTRATE

TABLE

MECHANICAL

DRIVE

Electron

Beam

Exposure

System

Figure

3

Computer

The

computerthat

servicesthe

electron-beamimaging

hardware

is

typically

very

powerful.High

speed

computing

power and

large

amounts ofmemory

are neededto

process

and

store

the

quantities ofdata

necessary

to

expose

a

wafer

ormask.

The

wafer and maskdesigns

aretypically

developed

using

computer-aided-design(CAD)

software.One

of

the

computer's

functions

is

to decode the CAD

files

which

control

[image:27.546.60.470.88.455.2]tasks

that

the

computer

performs

as partof

this

function.

The

computer

transfers

the

pattern

data from the CAD format to

a

decoded

format

which

the

computer

can

process.It

alsocontrols

the

hardware-exposure-control

activitiessuch

asbeam

deflection

and

blanking,

stage

movement,

and

loading

andunloading

substrates.

As

a

part

of

the

exposure-control

tasks,

the

computermay

correct

for proximity

effects.

Proximity

effects

result

from

the

distribution

of electrons asthey

scatter whentraveling

through

the

resist andbackscatter

whenthey

enterthe

substrate.

These

scattered electrons areundesirable,

since

they

tend

to

expose areas outsidethe

areaintended.

Therefore,

the total

energy

absorbedby

an areain

the

resist

is

dependent

on

the

"proximity"of adjacent

exposures

[Brewer,

1980].

Compensation

for proximity

effectsmay

be

executed

by

prior

programming to

adjustthe

exposure.This

correction

can

also

be

performedin

the

CAD

systemprior

to

decoding

the

pattern

data.

In

additionto

exposurecontrol,

the

computer

also

processes

the

registrationdata

neededto

align

the

substrates

to

the

successive masklevels

in

direct

-writeapplications.

Fiducial

marks are placed onthe

substratesor

stage

aspoints

of

reference sothat

adjustmentscan

be

madeto

account

for

beam

drift

causedby

process-induceddistortion,

vibration,

Elliott,

1985]

.At

the

alignment

-mark areasthe

electron

beam

is

used

more as ananalytical

tool

ratherthan

an exposuredevice.

Detection

ofthe

registration

markscan

be

achievedby

creating

a

difference

in

the

signal-to-noise ratioby

increasing

the

amount

ofbackscattered

electrons.This

canbe

done

by

etching

an areaof

the

substrate

ordepositing

a

material

with

adifferent

atomic

weight.

Once

the

fiducial

marks are

located,

the

beam

deflection

parameters arecorrected

through

variousalgorithms.

A

computer

is

well

suited

to

monitor signalchanges,

performthe

beam

correctionalgorithms,

andimplement

the

necessary

mechanical

adjustments.

Electron

Optical

Column

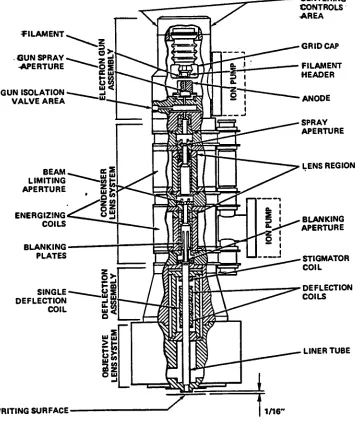

The

heart

ofany

electron-beamlithographic

systemis

the

electron optical column.

The

components ofthe

column

include

the

electronsource,

which produces aprimary

electron

beam;

the

electromagneticlenses

andapertures,

which

focus

the

primary

beam

onthe

target

and provide ameans

ofbeam

blanking;

and abeam

deflection

unit,

which

is

used

to

position

the

beam

precisely

andaccurately

overthe

scan

field.

Depending

onthe

purpose anddesign

of

a

particular

system,

it

is

possibleto

configurethese

elements

in

a

variety

of ways.Electron

gunelectrons

which

can

be

focused

onto

atarget

by

the

remaining

elements

of

the

electron

optical

column.

The

gun consists ofan

electron

source andelectrodes

usedto

acceleratethe

electrons

to

the

desired

beam

energy.

An

electricalpotential,

established

between

a cathodeand

anode,

attractsnegatively

charged

source electronsto

the

anode.This

voltage

difference

is

known

asthe

"accelerating

voltage".The

electrode

arrangementis

designed

sothat

the

traveling

electrons pass

through

an aperturein

the

anode andinto

the

lens

system.Electron

sources canbe

classifiedinto

two

groups,

depending

onthe

method usedto

emitthe

electrons.Thermionic

sourcesrely

onheating

amaterial

above atemperature

beyond

which

electrons areemitted

from

the

surface.

[Thompson,

etal.,

1983]

A

field

emitter

sourceconsists of a

high

electricalfield

surrounding

avery

sharp

tip

of material.The

electricalfield

extractselectrons

off

the

source material.There

arethree

materials which arepredominately

used

asthermionic

sources.These

aretungsten,

lanthanum hexaboride

(LaB6)

, andthoriated

tungsten.

The

tungsten

material

is

typically

bent

to

form

atight

radiusin

order

to

create

asmall

emitting

area atthe

tip.

The

tungsten

hairpin

is

popular

for

usein

electron microscopesbecause

of

its

ease of

fabrication,

andmaintainability.

However,

the

life

and

relative

brightness

of

these

sourcesis

lower

than

the

other

materials.

[Elliott,

1985]

The

work

function

of

the

LaB6

material

is

muchlower than

tungsten.

Therefore,

the

brightness

is

an order of magnitudegreater

at

lower

operating

temperatures.

[Brewer,

1980;

Thompson,

etal.,

1983]

These

sources mustbe

used

under

higher

and more stable vacuum pressuresto

achievelonger life

potential.

A

tungsten

surface whichhas

been

carburizedat

high

temperatures

becomes

thoriated

tungsten.

These

sourcesalso

have

alower

workfunction

than tungsten.

The

brightness

andlife

increase

underlower

operating

temperatures.

These

materials require more stable vacuums

and,

because

of

the

additional

processing,

are moredifficult

to

manufacture.

A

field

emitter sourceis

typically

atungsten

rod

with

a

very

precisely

polishedtip.

The

relativebrightness

andlife

ofthis

sourceis

considerably

higher

than

thermionic

sources.

However,

these

sources are morecomplicated

to

fabricate

andthey

requirevery

high

vacuumconditions.

Lenses

Because

electrons are chargedparticles,

their

traveling

path can

be

altered asthey

passthrough

magnetic

fields.

The

electromagnetic

lenses.

The

lenses

arebasically

alength

of

wire

wound

around

an

iron

core.

The

magnitude

of

an

electrical

current

applied

to

the

wire

is

proportional

to

the

magnetic

field

strength

of

the

lens.

The

amount

that

the

electron

beam

is

effected

by

the

lenses

is

related

to

the

field

strength

ofthe

lens,

the

velocity

ofthe electrons,

andthe

relative

anglebetween

the

electron

path

and

the

magnetic

field

lines.

[Postek,

etal.,

1980]

The

lens

section

of

the

electron opticalcolumn

consists

of a series of electromagnetic

lenses

and apertures whichshape,

demagnify,

andfocus

the

electronbeam.

There

areseveral sections of

the

lens

systemwhich

can

be

groupedby

task.

The

condenserlens

follows

the

electron

gun

andis

the

first

to

effectthe

beam.

This

lens

may

be

madeof

several

lenses

whichdemagnify

the

beam

through

afocal

point.

There

is

usually

an aperturein

this

area whichblocks

stray

electrons and

thereby

homogenizes

the

beam.

Following

the

condenserlens

seriesis

an

assembly

of

deflection

lenses.

The

function

ofthis

group

is

to

deflect

the beam

overthe

scanfield

onthe target.

This

assembly may

also

include

a

mechanism usedto

blank

the

beam

and

lenses

which correct

for

aberrations and astigmatismcreated

in

the

entire

lens

system.Finally,

there

is

an objectivelens that

demagnifies the

Beam

Control

The

exposure

systemmust

employ

a mechanical stage systemin

addition

to

the

deflection

lens

assembly

in

orderto

control

the

beam

and

expose

the

entire

substrate.The

stageuses either

roller

bearings

or

an externalair

bearing

to

enable

x-y

motion.

The

stage

should

be

madefrom

non

magneticmaterials,

since

distortion

of

the

beam

patterncould

resultotherwise.

Typically,

astep

and repeat modeis

usedto

expose aportion of

the

substratein

the

target

area whilethe

stageremains stationary.

The

stageis

steppedto

an

adjacent

area

so

that

the

next

section ofthe

substrate canbe

exposed.

This

processis

continually

repeateduntil

the

entire

substrate

is

exposed.An

alternate method wouldbe to

expose

the

substrate whilethe

stageis

under continuousmotion.

In

eithermethod,

a registration systemis

used

to

repeatedly locate the

stageaccurately

in

the

proper position.

The

registration system must provide a meansfor

detection

andfeedback

of aknown

reference pointeither

on

the

stage

or

the

substrate.

There

aretwo

popular methodsto

perform

this

task.

As

described

previously,

the

signal-to-noise

ratio

changes

of

the

electronbackscatter

atthe

substrate

surface

can

be

detected.

Also,

alaser

interferometry

technique

can

Support

Equipment

There

are

several

reason

why

an electron-beam system mustbe

operated

under

ahigh

vacuum.

The

column mustbe

kept

extremely

clean.

Dirt that

has been

deposited

onthe

wallsof

the

column

or

that

is

suspended

in

the

beam

path

can

become

charged

and

deflect

or

block

the

beam.

Air

present

in

the

system

will

cause

fast

oxidation

of

the

filament

which

wouldresult

in

extremely

low

life.

Also,

air

molecules

will

scatter

the

beam

electrons.A

pumping

systemis

used

to

createthe

vacuumnecessary

in

the

exposureinstrument.

More

than

onepump

is

usedin

order

to

attain

the

high

vacuumsrequired.

A

mechanical,

orroughing,

pump is

usedinitially

during

the pump down

cycleto

reach

the

range of 10"2torr.

These

pumpscould

be

used

to

reduce

the

pressurefurther,

but their

efficiency is

decreased

as

the

vacuumincreases.

This

would

require

avery

long

time

to

reachthe working

pressure.Therefore,

a

diffusion pump

is

used

in

combination withthe

roughing

pump.Once

the roughing

pump

decreases

the

vacuumto

a

specific pressurethe diffusion

pump

will activate and continueto

reduce

the

pressure

to the

required point.

Electron-beam

systems require capablepower

supplies.

The

supply

usedto

powerthe

computer mustbe

filtered

and

highly

regulatedin

orderto

reducethe

chances

of

inaccurate

surges or

irregularities.

The

high

voltage powersupply

usedfor

the

electron

gunmust

be

stableand

capable

of

the

required

current

to

alleviate

any

beam

fluctuations.

Because

of

the

high

resolutions andtolerances

expected

in

electron-beam

systems,

they

mustbe

usedin

tightly

controlled

environments.

Normally

these

units areoperated

in

a

clean-room

atmospherewhere

the

cleanliness,

temperature,

and

humidity

levels

are monitored and maintained.Other

environmental

considerations wouldbe

vibrationisolation

and

suppression of electromagnetic

interference.

Scanning

Electron

Microscope

The

exposure system usedfor

Phase

I

ofthis

experiment

is

aStereoscan

S600

Scanning

Electron Microscope

manufactured

by

Cambridge

Instruments.

It

is

designed

as a stand-aloneanalytical

instrument

withaccompanying

supportequipment

andis

notinterfaced

to

any

computersystem.

A

crosssection

of

this

SEM

is

found

in

Figure

4.

The

electron gun ofthis

systemuses

a

fixed

hairpin

tungsten

filament

asthe

electron source.The

potential

of

the

electron gun canbe

selected at either1.5,

7.5,

15,

or25KeV.

The

gunassembly

also contains alignmentcoils

which

are

usedto

adjustthe

beam

relativeto

the

optical

axis.

A

double

condenserlens

and anobjective

lens

ElectronGun

Alignment Coll

CondenserLeneec

Aperture

SecondaryElectron Detector

StlgmatorColl

AirLock Valve

DeflectionColli

Specimen

Scanning

Electron

Microscope

Figure

4

condenser

lens tube

containsthe

spray

apertures

used

to

clean

up

the

beam.

The

scanning

coilassembly

is

located

in

the

objectivelens

tube.

This

assembly

includes

the

stigmator,

micro-shift,

anddeflection

coils.The

chosen

final

aperture

is

alsolocated

in

the

objectivelens

tube.

Just

below

this

final

lens

assembly

is

the

specimen

chamber.

Access

to

this

chamber

is

obtained

through

arectangular

opening

atthe

side

of

the

electron

optical

column.

The

specimen stageis

acomplex mechanical

device

and

is

an

integral

part ofthe

column.The

stage

provides

[image:36.546.143.410.61.318.2]is

capable

ofX,

Y,

Z,

rotation,

and

tilt

movement

of

the

specimen.

External

controls

used

to

execute

these

movementsare

located

on afront

platewhich

also providesa

meansto

seal

the

column

once

the

stage

is

inserted

into the

specimen

chamber

.The

main

beam

control

is

available

by

manually adjusting

the

specimen

relative

to

the

beam.

There

is

also

a

meansof

providing

slightadjustment

to

the

electronbeam

using

the

micro-shift

controls.This

SEM

has

an

automatically

controlledvacuum

system.

The

vacuum systemincludes

a

rotary

roughing

pump,

diffusion

pump,

and associated control units.The

controlassemblies

contain various

valves,

gauges,

and controllogic

with

feedback to

enablethe

vacuum systemto

operateautomatically.

The

SEM

is

also equipped with an optionaldry

nitrogen

back

filling

systemto

help

protectthe

vacuum systemfrom

dirt

andmoisture.

Power

is

suppliedto

the

instrument

through

a

standard

domestic

socket.However,

the

SEM

has

powersupplies

to

provide power

levels

necessary

to

operateall

internal

systems.

For

a moredetailed description

ofthis SEM

instrument it

is

recommendedthat

the

reader referencethe

Stereoscan

S600

Mask

Making

Electron-Beam Exposure System

A

mask

making

electron-beam

exposure

system

(MEBES)

wasused

as

the

exposure

source

for

the

study

of

chemically

amplified

resist

material

in

Phase

II

of

this

project.

The

unit

was

designed

and

built

by

ETEC

specifically

for

mask

making

.This

unit

is

interfaced

to

a

Data

General

Nova

computer

system.

The

computer

system

runs

with

RDOS

operating

language.

It

is

supported

with

several

software

packages

androutines.

These

packagesinclude

"MEBES

"which

interprets

ajob

for

the

hardware,

"CHECKSPEC"and "CHECKPAT"

which

are

used

to verify the

job

deck

and

pattern

being

exposed.

"ASOP"is

used

to

set

the

operation

parametersof

components

in

the

electron

optical

column.A

cross sectionof

the

MEBES

electron

optical

column

is

depicted

in

Figure

5.

The

electronoptical

column

is

composed

of

the

electron gunassembly,

the

condenserlens

system,

the

deflection

assembly,

andthe

objectivelens

system.

The

gun

assembly

usesa

thermionic

tungsten

hairpin

filament

as

the

electron source.

The

potential

of

the

electron

gun

is

set

to

lOKeV.

This

gun

outputsapproximately

3xl05A/cm2sr

source

brightness.

The

gun

has centering

coil

control

used

to

adjust

the beam.

A

spray

apertureis

included

to

assist

in

cleanin