Effects of Canola Biodiesel on a DI Diesel Engine

Performance and Emissions

Murari Mohon Roy, Majed Alawi and Wilson Wang

Abstract

-

A direct injection (DI) diesel engine is tested with different biodiesel-diesel blends, such as B0 (neat diesel), B5 (i.e., 5 vol. % biodiesel and 95 vol. % diesel), B10 (10 vol. % biodiesel), B20 (20 vol. % biodiesel), B50 (50 vol. % biodiesel), and B100 (neat biodiesel) for performance and emissions under different load conditions. Engine performance is examined by measuring brake specific fuel consumption (bsfc) and fuel conversion efficiency (ηf). The emission of carbon monoxide (CO), hydrocarbon (HC), nitric oxide (NO), nitrogen dioxide (NO2), nitrogen oxides (NOx), carbon dioxide (CO2) and others are measured. Biodiesel shows a significant CO and HC reduction compared to diesel under low load operation; under high load operation, however, CO with biodiesel is increased a little and HC emissions are very similar to that with diesel. On the other hand, under low load operation, NOx emission with biodiesel is significantly increased than diesel; however, under high load operation, there is almost no change in NOx emissions with biodiesel and diesel.Index Term

-

Canola biodiesel, diesel engine, engine performance, exhaust emissions.I.

INTRODUCTIONThe growing concern on environmental pollution caused by the extensive use of conventional fossil fuels has led to search for more environment friendly and renewable fuels. On the other hand, climate change and mitigation of greenhouse gas (GHG) emissions have motivated R&D of biofuels. Biofuels such as alcohols and biodiesel have been proposed as alternatives for internal combustion engines [1], [2]. In particular, biodiesel has received wide attention as a replacement for diesel fuels because it emits less GHG and other pollutants. Biodiesel can reduce net carbon-dioxide emissions by 78% on a lifecycle basis when compared to conventional diesel fuel [3]. United States Environmental Protection Agency (US EPA) has done a comprehensive analysis of biodiesel impacts on exhaust emissions [4] mentioning that pure biodiesel can reduce HC as high as 70% and PM and CO about 50% when compared with conventional diesel fuel.

Murari Mohon Roy is with the Department of Mechanical Engineering, Lakehead University, 955 Oliver Road, Thunder Bay, Ontario, P7B 5E1, Canada, (Corresponding author: Phone 1 807 766 7175, Fax: 1 807 346 7943,

E-mail: mmroy@lakeheadu.ca).

Majed Alawi is with the Control Engineering, Lakehead University, 955 Oliver Road, Thunder Bay, Ontario, P7B 5E1, Canada, (E-mail:

malawi@lakeheadu.ca).

Wilson Wang is with the Department of Mechanical Engineering, Lakehead University, 955 Oliver Road, Thunder Bay, Ontario, P7B 5E1, Canada,

(E-mail: wwang3@lakeheadu.ca).

Several countries including Canada have already begun substituting the conventional diesel by a certain amount of biodiesel. The use of biodiesel is being promoted by European Union countries to partly replace petroleum diesel in order to reduce GHG effect and dependency on foreign oil. Meeting the targets established by the European Parliament for 2020 would lead to a biofuel market share of 10% [5]. Canadian government has launched a new biofuel strategy to use up to 5% biodiesel in diesel for ground transportation and heating by 2015.

Biodiesel is mainly produced from different types of vegetable oils (e.g., rapeseed, soybean, canola, sunflower, palm oil, etc.). Canola oil is one of the leading feedstock for biodiesel production in Canada. Transesterification is regarded as one of the most efficient methods to produce biodiesel from vegetable oils due to its low cost and simplicity [6], [7]. Thus, this study will choose canola oil as feedstock and use transesterification process to produce biodiesel.

Many investigations have indicated that the use of biodiesel can result in a substantial reduction in PM, HC and CO emissions [8]-[13], even though a slight increase in NOx emission is observed by most researchers when biodiesel is used [14]-[16]. Wu et al. [12] investigated the emission performance for five pure biodiesels on a Cummins ISBe6 DI engine with turbocharger and intercooler; it was found that the related biodiesels could reduce PM emission by 53–69% on average compared with the diesel fuel. Lin et al. [13] also observed that there was significant reduction (ranging from 50% to 73%) in the smoke emission for 8 kinds of biodiesels compared with petroleum diesel. On the other hand, a small portion of authors found that there was no difference in PM emissions for biodiesel relative to diesel [17], [18], or even there was a bit increase [19], [20].

According to most of literatures, it was a common trend that CO emissions could be reduced when diesel was replaced by pure biodiesel [8]-[11], [21]-[23]. For example, Krahl et al.

[21] obtained about 50% reduction in CO emissions for biodiesel from rapeseed oil compared to low and ultra-low sulphur diesel. A higher reduction in CO emissions was reported by Raheman and Phadatare (up to 73–94% for the karanja biodiesel and its blends compared to diesel) [22], and by Ozsezen (87% for waste palm oil biodiesel and 73% for canola biodiesel) [23]. However, some literature showed the less reduction; for example, Utlu and Kocak [24] obtained CO reduction of only about 17% than diesel fuel. Some authors found different trend at different load conditions; for example,

An et al. [25] reported that although CO reduced at high load

reported the increase in CO emissions for pure biodiesel [26], [27]; for example, Banapurmatha et al. [26] observed higher CO emissions for jatropha, honge and sesame biodiesel compared to diesel on a single-cylinder, 4-stroke, DI diesel engine at a rated speed of 1500 rpm at 80% load. Macor et al.

[27] reported a slight CO increase with biodiesel than diesel. Most literatures found reductions in HC emissions when pure biodiesel was fuelled instead of diesel [11]-[13], [26], [28]. Ng et al. [11] showed that engine-out HC concentration reduced with increasing biodiesel content in blend and HC concentration of neat palm biodiesel was 26.2% lower than that of fossil diesel. Wu et al. [12] reported that the 5 different biodiesels could reduce HC emission by 45–67% on average compared with diesel fuel. Puhan et al. [28] found that the average reduction in HC emissions was around 63% for biodiesel compared with diesel. But some authors reported the lower decreases, for example, in the range of 22–33% for 8 kinds of biodiesels from Lin et al. [13]. However, Banapurmatha et al. [26] and Macor et al. [27] found higher HC emissions with different biodiesels compared to diesel fuel.

In NOx emissions from biodiesel operation, there is a divided opinion or results in literatures. Many literatures believed that the use of pure biodiesel would cause the increase in NOx emissions [13], [14]-[16], [23], [29]. For example, a maximum of 15% increase in NOx emissions for neat biodiesel was observed at high load condition as the results of 12% oxygen content of biodiesel and higher gas temperature in combustion chamber [29]. Ozsezen et al. [23] found that NOx could increase by 22% and about 6%, respectively, by waste palm and canola biodiesels. Lin et al.

[13] compared 8 kinds of biodiesel mentioned above and found that using biodiesel in the diesel engine could yield higher NOx emissions, ranging from an increase of about 6% to 26% when compared to diesel. Several others [26], [28], [30] reported that NOx emissions would reduce when using biodiesel; for example, Puhan et al. [28] found that the average reduction of NOx in the case of Mohua biodiesel was around 12% compared with the diesel fuel at the whole range of load. Dorado et al. [30] obtained that NOx emissions reduced by over 20% for biodiesel from waste olive oil with 8-mode test cycles. Banapurmatha et al. [26] reported that NOx emission values became less for biodiesels than diesel. Canola oil based biodiesel and its blends with diesel have been investigated in diesel engines for engine performance and emissions [23], [31], [32]. Ozsezen and Canakci [23] studied engine performance and emissions with canola and waste palm biodiesel and compared with diesel’s performance and emissions; they found shorter ignition delay and earlier fuel injection, which affected the start of combustion, combustion duration, peak cylinder pressure and temperature, thus reducing unburned HC, CO and smoke opacity, but increasing NOx formation. Sayin et al. [31] investigated combustion and engine performance at different injection pressures with canola biodiesel and its blends with diesel. They reported higher bsfc and lower thermal efficiency with

canola biodiesel than that of diesel. A DI diesel engine was tested in [32] with pure and used canola biodiesel-diesel blends for performance and emissions at low load-high speed conditions (high idling operations). Biodiesels were blended with petroleum diesel 2-20 volume percent. CO and HC emissions from biodiesel-diesel blends were significantly less than neat diesel fuel. Although there was no increase in bsfc, NO, NO2 and NOx emissions up to 5% biodiesel in the blends, B20 or UCB20 (used canola biodiesel 20 vol. %) had 12-26% NOx increase. NO2 production at high idling operations was found very significant and even higher than NO production and its share in total NOx was more than 50%.

In general, engine parameters have significant effect on performance and emissions of diesel engine when running with biodiesel and its blends with diesel. Hence, a study has already been undertaken at the authors’ research group to gather information on the behavior of a diesel engine when operated with biodiesel-diesel blends. Canola biodiesel percentage in diesel will be extended to 100% (pure biodiesel) in this study than previous study [32] in which 20 vol % biodiesel was investigated. Furthermore, engine tests will be carried out at three loading conditions (low, medium and high) at the rated engine speed of 1800 rpm.

Consequently, the objective of this research is to investigate the effect of canola biodiesel and their blends on performance and emissions of a DI diesel engine at different loading conditions at constant rated speed. NOx has two components, NO and NO2, which cannot be measured separately by most of the exhaust gas analyzers in diesel emission research. Usually NO is measured and NO2 is considered a certain percentage of total NOx (usually 5%). Therefore, there are hardly any separate data of NO and NO2 in diesel emission research. However, this is important to know the actual share of NO and NO2 emissions at different engine conditions. This study measures NO and NO2 individually at different engine conditions and compares the share of NO and NO2 in total NOx.

II. MATERIAL AND METHODS

To produce biodiesel, canola oil was used as feedstock. Pure canola oil was purchased from a local supermarket. Two main ingredients for biodiesel production were methanol and sodium hydroxide that were purchased from Canadawide Scientific Ltd. The quality of produced biodiesel was tested according to ASTM 6751. A DI diesel engine was tested to examine its performance and emissions with different biodiesel-diesel blends (B0, B5, B10, B20, B50 and B100).

A. Biodiesel Production and Properties

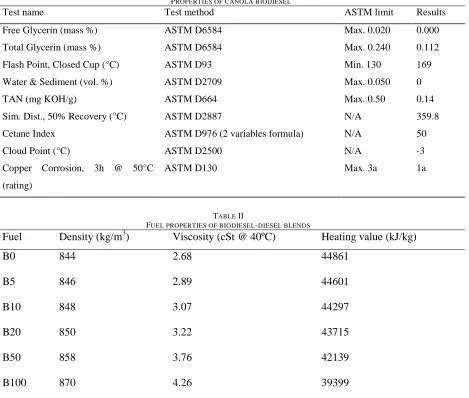

biodiesel followed in this study is from ref. [33]. One liter biodiesel was produced from one liter of canola oil and the final collection efficiency (after washing) was 86%. Table I summarizes the properties of biodiesels tested by Bently Tribology Services. All the properties are satisfactory according to ASTM limit. Furthermore, advanced investigation was performed in this study on density, viscosity and heating value and the results are summarized in Table II.

B. Engine Test

Figure 1 shows the schematic diagram of engine experiment. The engine used in this study is a Peter diesel engine (model PH2W), which is a four-stroke two-cylinder naturally aspirated DI diesel engine and its specifications are summarized in Table III. All experimental data were taken after engine warm-up (about 20 minutes after start). In this condition, there was almost no fluctuation of emissions. Tests were carried out at the warmed up condition of

TABLE I

PROPERTIES OF CANOLA BIODIESEL

Test name Test method ASTM limit Results

Free Glycerin (mass %) ASTM D6584 Max. 0.020 0.000

Total Glycerin (mass %) ASTM D6584 Max. 0.240 0.112

Flash Point, Closed Cup (°C) ASTM D93 Min. 130 169

Water & Sediment (vol. %) ASTM D2709 Max. 0.050 0

TAN (mg KOH/g) ASTM D664 Max. 0.50 0.14

Sim. Dist., 50% Recovery (°C) ASTM D2887 N/A 359.8

Cetane Index ASTM D976 (2 variables formula) N/A 50

Cloud Point (°C) ASTM D2500 N/A -3

Copper Corrosion, 3h @ 50°C (rating)

ASTM D130 Max. 3a 1a

TABLE II

FUEL PROPERTIES OF BIODIESEL-DIESEL BLENDS

Fuel

Density (kg/m

3)

Viscosity (cSt @ 40ºC)

Heating value (kJ/kg)

B0

844

2.68

44861

B5

846

2.89

44601

B10

848

3.07

44297

B20

850

3.22

43715

B50

858

3.76

42139

B100

870

4.26

39399

the engine under three engine loads at the rated speed of 1800 rpm. Table IV shows engine operating conditions for different fuels. Loads were measured by a water brake dynamometer. The fuel supply control system was used to switch between the diesel fuel used as a standard and the test fuels. The engine was started using diesel; once the engine warmed up, it was switched to biodiesel-diesel blends. After concluding the tests, the engine was again switched back to diesel before stopping the engine until the blends were purged from the fuel line, injection pump and injector. Engine load and fuel

consumption were measured to calculate brake specific fuel consumption and fuel conversion efficiency of the engine. A multi-gas analyzer (NOVA Model 7466 PK) and a CO analyzer (Dwyer 1205A) were used to measure the CO, NO, NO2, HC, CO2 and O2 of exhaust gases corresponding to each data point.

Fig. 1. Schematic diagram of engine experiment [ref. 32]

TABLE III ENGINE SPECIFICATIONS

Engine make and model Lister Peter; PH2W

Engine type Four stroke DI diesel engine

Number of cylinder Two

Bore × Stroke 87.3 × 110 mm

Swept volume 1318 cc

Compression ratio 16.5 : 1

Rated power 11.2 kW @ 1800 rpm

Fuel injection timing 24ºBTDC (below 1650 rpm); 28ºBTDC (above 1650 rpm)

Injector nozzle opening pressure 15.5 MPa (below 1100 rpm); 22 MPa (above 1100 rpm)

Diesel burette

Blend Fuel

burette

Control Valves

Test Engine

(DI diesel)

Dynamometer

(Water brake)

Data Acquisition System

(Torque, power, etc.)

CO Analyzer

HC

Multi-Gas Analyzer

Exhaust

O

2NO

CO

2NO

2Diesel burette

Blend Fuel

burette

Control Valves

Test Engine

(DI diesel)

Dynamometer

(Water brake)

Data Acquisition System

(Torque, power, etc.)

CO Analyzer

HC

Multi-Gas Analyzer

Exhaust

O

2NO

CO

2TABLE IV

ENGINE OPERATING CONDITIONS Engine speed

(rpm)

Rated power (kW)

Load Actual power

(kW)

bmep (kPa)

Load (%)

1800 11.2

Low 0.34 16 3

Medium 5.38 272 48

High 10.75 545 96

III. RESULTS AND DISCUSSION

A. Engine Performance

Figure 2 shows the variation of bsfc of the engine with different canola biodiesel-diesel blends at different loads. At all loads, there is an increase in bsfc with higher biodiesel-diesel blends than neat biodiesel-diesel. The bsfc of B100 increases about 4.5% at low load condition and increases to about 8.5% at high load operation. B100 has about 12% less heating value than diesel fuel (Table II), but it shows less bsfc increase (e.g., 4.5-8.5%) at different loads. This indicates that biodiesel has higher fuel conversion efficiency than that of diesel fuel. The variation of fuel conversion efficiency of the engine with various fuels is demonstrated in Figure 3. B100 shows about 8% higher efficiency than diesel at low and medium load conditions and about 5% under high load operation. A higher efficiency with B100 at each engine load supports less bsfc increase of B100 than it should have been according to its calorific value. Other biodiesel-diesel blends show similar trend. Furthermore, the higher efficiency with biodiesel-diesel blends than diesel indicates that blend fuels combustion is better than diesel fuel combustion. This is attributed to oxygen content (about 9%) of biodiesel. Due to better combustion with biodiesel, less emission of CO and HC is expected. The CO and HC emission results will be discussed in the following subsection.

B. Emissions

The emissions of CO, HC, NO, NO2 and NOx are illustrated in Figures 4-6. Figure 4 illustrates CO emissions at different engine

loads

for various fuels. At low load condition, diesel fuel produces the maximum CO (about 200 g/kWh), which decreases gradually with biodiesel-diesel blends and becomes the lowest (about 123 g/kWh) for B100 (which is approximately 39% lower). At medium load, diesel fuel again produces the maximum CO (7.83 g/kWh). With B100, it is approximately 18% lower than that of diesel. At high load, on the other hand, diesel fuel produces 2.67 g/kWh and B100 gives a slight increase in CO (about 5%).Fig. 2. Variation of bsfc of different biodiesel-diesel blends at different engine loads

Fig. 3. Variation of ηf of different biodiesel-diesel blends at different engine

loads

medium load conditions. This is thought to be due to higher O2 concentration in the air-fuel mixture, which can improve combustion and enhance further CO oxidation; 3) at high load operation, biodiesel no longer reduces the CO emissions than diesel. At this condition, the in-cylinder temperature with diesel is higher than that of biodiesel, and this fact is supported by higher exhaust gas temperature of 360ºC for diesel and 304ºC for biodiesel. The mixture is still leaner than stoichiometric for both the fuels (excess oxygen in exhaust gases supports this claim). The higher in-cylinder temperature seems to dominate over fuel-bound O2 effect in biodiesel at high load operation. Therefore, it may be concluded that biodiesel is superior to diesel in terms of CO emissions up to a certain engine load (up to medium load in this study).

Figure 5 demonstrates HC emissions at different engine loads for various fuels. At low load, diesel fuel produces 30.47 g/kWh of HC; it decreases gradually with biodiesel-diesel blends and becomes about 56% lower for B100. At medium load, diesel fuel produces 1.04 g/kWh HC, and then decreases to 0.63 g/kWh for B100 (about 39% reduction). At high load, diesel fuel produces 0.52 g/kWh of HC; B100 shows only about 12% reduction. Similarly, the following observations can be made: 1) the higher the engine load, the lower the HC emissions for all fuels. This phenomenon can be attributed to better mixing of air and fuel due to higher evaporation at higher engine loads for higher in-cylinder temperatures; 2) the higher the biodiesel percentage in biodiesel-diesel blends, the lower the HC emissions. This is due to the fact that higher O2 concentration in the air-fuel mixture can help enhance oxidation of unburned hydrocarbons; 3) at high load, HC reduction with biodiesel is lower than at lower loads. The beneficial effect of the presence of O2 in biodiesel is not very significant at high load operation.

Fig. 4. CO emissions of different biodiesel-diesel blends at different engine loads

Fig. 5. HC emissions of different biodiesel-diesel blends at different engine loads

Fig. 6. NO, NO2 and NOx emissions of different biodiesel-diesel blends at

different engine loads

IV.

CONCLUSIONS

An experimental investigation has been conducted to explore the performance and emissions of biodiesel blends on a small DI diesel engine. The results obtained suggest the following conclusions:

1) There is a little (less than 1%) fuel penalty up to 10% blend of biodiesel in diesel, and B100 shows 4.5%, 5.5% and 8.5% fuel penalty than diesel at low, medium and high loads, respectively. Biodiesel-diesel blends provide higher fuel conversion efficiency than that of neat diesel: 5% higher at high load condition and 8% higher at low to medium load conditions.

2) CO emissions for all fuels are lower at high load condition; the higher the biodiesel percentage in biodiesel-diesel blends, the lower the CO emissions are at low to

medium load conditions. B100 shows about 39% and 18% CO reduction than diesel at low and medium load conditions, respectively, whereas at high load condition B100 generates about 5% increase in CO emissions than that of diesel. 3) HC emissions for all fuels are also lower at higher loads; the higher the biodiesel percentage in biodiesel-diesel blends, the lower the HC emissions are, a similar trend to that of CO emissions. B100 gives about 56%, 40% and 12% HC reduction than diesel at low, medium and high load conditions, respectively.

4) The highest NO is emitted at high load condition for all fuels; however, NO2 emissions are the lowest at high load operation. NOx emissions with different biodiesel-diesel blends are only 1-4% higher at high and medium load conditions, whereas at low load operation, NOx increase is up to 35% for B100 than diesel. The shares of NO2 in total NOx are approximately 8% and 23% at high and medium loads, respectively. NO2 production at low load operation is found very significant and even higher than NO production and its share in total NOx is 68%.

Advanced research is to be undertaken in the following areas:

1) Comparison of particulate matter (PM) of different canola biodiesel-diesel blends at different engine conditions, and 2) Development of a proper biodiesel mix that can be used in cold climate conditions.

ACKNOWLEDGEMENTS

This project was financially supported by Lakehead University and the Natural Sciences and Engineering Research Council of Canada (NSERC). Thanks are also given to Mr. Kailas Bhatia and Mr. Joe Ripku, technologists in the Department of Mechanical Engineering of Lakehead University, for their help in engine tests and measurement.

REFERENCES

[1] Agarwal AK. Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog Energ Combust Sci 2007;33:233–71.

[2] Demirbas A. Progress and recent trends in biofuels. Prog Energ Combust Sci 2007;33:1–18.

[3] Sheehan J, Camobreco JD, Graboski M, Shapouri H. Life cycle inventory of biodiesel and petroleum diesel for use in an urban bus, Final report for U.S. Dept. of Energy’s Office of Fuel Development and the U.S. Dept. of Agriculture’s Office of Energy, by the National Renewable Energy Laboratory, 1998; NERL/SR-580-24089. [4] USEPA. A comprehensive analysis of biodiesel impacts on exhaust

emissions. EPA420-P-02-001; 2002.

[5] Directive 2009/28/EC. On the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC. OJEU 2009; L 140:16-62. [6] Sharma YC, Singh B. Development of biodiesel: current scenario.

Renew Sustain Energy Rev 2009;13(6–7):1646–51.

[7] Balat M, Balat H. Progress in biodiesel processing. Appl Energy 2010;87(6):1815–35.

[8] Kannan GR, Karvembu R, Anand R. Effect of metal based additive on performance emission and combustion characteristics of diesel engine fuelled with biodiesel. Appl Energy 2011;88(11):3694-3703. [9] Di Y, Cheung CS, Huang ZH. Experimental investigation on

[10] Buyukkaya E. Effects of biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2010;89:3099–105. [11] Ng JH, Ng HK, Gan SY. Characterisation of engine-out responses

from a light duty diesel engine fuelled with palm methyl ester (PME). Appl Energy 2012;90:58–67.

[12] Wu F, Wang J, Chen W, Shuai S. A study on emission performance of a diesel engine fueled with five typical methyl ester biodiesels. Atmos Environ 2009;43(7):1481–5.

[13] Lin B-F, Huang J-H, Huang D-Y. Experimental study of the effects of vegetable oil methyl ester on DI diesel engine performance characteristics and pollutant emissions. Fuel 2009;88:1779–85. [14] Hazar H. Cotton methyl ester usage in a diesel engine equipped with

insulated combustion chamber. Appl Energy 2010;87(1):134-40. [15] Sun JF, Caton JA, Jacobs TJ. Oxides of nitrogen emissions from

biodiesel-fuelled diesel engines. Prog Energy Combust 2010;36:677– 95.

[16] Xue JL, Grift TE, Hansen AC. Effect of biodiesel on engine performances and emissions. Renew Sust Energy Rev 2011;15:1098– 116.

[17] Turrio-Baldassarri L, Battistelli CL, Conti L, Crebelli R, De Berardis B, Iamiceli AL, et al. Emission comparison of urban bus engine fuelled with diesel oil and biodiesel blend. Sci Total Environ 2004;327:147–62.

[18] Qi DH, Chen H, Geng LM, Bian YZH. Experimental studies on the combustion characteristics and performance of a direct injection engine fueled with biodiesel/diesel blends. Energ Convers Manage 2010;51:2985–92.

[19] Aydin H, Bayindir H. Performance and emission analysis of cottonseed oil methyl ester in a diesel engine. Renew Energ 2010;35:588–92.

[20] Armas O, Yehliu K, Boehman AL. Effect of alternative fuels on exhaust emissions during diesel engine operation with matched combustion phasing. Fuel 2010;89:438–56.

[21] Krahl J, Munack A, Schroder O, Stein H, Bunger J. Influence of biodiesel and different designed diesel fuels on the exhaust gas emissions and health effects. SAE paper 2003, 2003-01-3199. [22] Raheman H, Phadatare AG. Diesel engine emissions and performance

from blends of karanja methyl ester and diesel. Biomass Bioenerg 2004;27:393–7.

[23] Ozsezen AN, Canakci M, Turkcan A, Sayin C. Performance and combustion characteristics of a DI diesel engine fueled with waste palm oil and canola oil methyl esters. Fuel 2009;88:629–36.

[24] Utlu Z, Kocak MS. The effect of biodiesel fuel obtained from waste frying oil on direct injection diesel engine performance and exhaust emissions. Renew Energ 2008;33:1936–41.

[25] An H, Yang WM, Chou SK, Chua KJ. Combustion and emissions characteristics of diesel engine fueled by biodiesel at partial load conditions. Appl Energy 2012;99:363–71.

[26] Banapurmatha NR, Tewaria PG, Hosmath RS. Performance and emission characteristics of a DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters. Renew Energ 2008;33:1982–8.

[27] Macor A, Avella F, Faedo D. Effects of 30% v/v biodiesel/diesel fuel blend on regulated and unregulated pollutant emissions from diesel engines. Appl Energy 2011;88(12):4989-5001.

[28] Puhan S, Vedaraman N, Sankaranarayanan G, Bharat Ram BV. Performance and emission study of Mahua oil (Madhuca indica oil) ethyl ester in a 4-stroke natural aspirated direct injection diesel engine. Renew Energ 2005;30:1269–78.

[29] Nabi MN, Najmul Hoque SM, Akhter MS. Karanja (Pongamia Pinnata) biodiesel production in Bangladesh, characterization of karanja biodiesel and its effect on diesel emissions. Fuel Process Technol 2009;90:1080–6.

[30] Dorado MP, Ballesteros E, Arnal JM, Gomez J, Lopez FJ. Exhaust emissions form a diesel engine fueled with transesterified waste olive oil. Fuel 2003;82:1311–5.

[31] Sayin C, Gumus M, Canakci M. Effect of fuel injection pressure on the injection, combustion and performance characteristics of a DI

diesel engine fueled with canola oil methyl esters-diesel fuel blends. Biomass Bioenergy 2012;46:435-46.

[32] Roy MM, Wang W, Bujold J. Biodiesel production and comparison of emissions of a DI diesel engine fueled by biodiesel–diesel and canola oil–diesel blends at high idling operations. Appl Energy 2013;106:198-208.

[33] Make your own biodiesel.

http://journeytoforever.org/biodiesel_make.html.

[34] Varatharajana K, M. Cheralathan M. Influence of fuel properties and composition on NOx emissions from biodiesel powered diesel engines: A review. Renew Sustain Energ Rev 2012;16:3702– 10. [35] EPA. Nitrogen oxides (NOx), why and how they are controlled. US

Environmental Protection Agency.

http://www.epa.gov/ttn/catc/dir1/fnoxdoc.pdf.

![Fig. 1. Schematic diagram of engine experiment [ref. 32]](https://thumb-us.123doks.com/thumbv2/123dok_us/1372959.1647357/4.612.55.505.85.632/fig-schematic-diagram-engine-experiment-ref.webp)